Testing the Durability of 3D Printed Parts

Sintratec, a Swiss startup specializing in Selective Laser Sintering (SLS) 3D printers, is in the process of testing their new machine, the Sintratec S2.

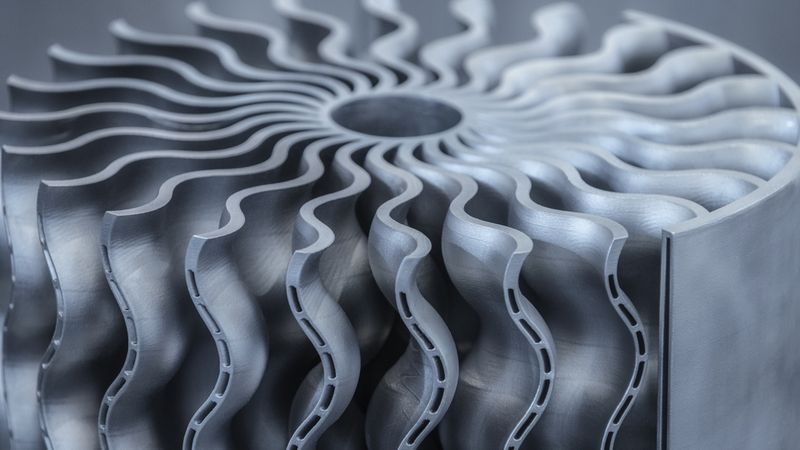

Aircraft turbine wheel printed on metal 3D printer.

When 3D printed parts are used in any application, their failure can result in dangerous situations. If a part isn't durable, it might break under pressure, resulting in equipment malfunction or even injuries. Testing is crucial for manufacturers to determine the suitability of different materials for their specific applications. By subjecting the components printed by the Sintratec S2 to rigorous testing, Sintratec can identify their strengths and weaknesses, ensuring that only durable and high-quality 3D-printed parts are released to the market.

This article explores the robust testing processes and the impressive resilience displayed by the Sintratec S2 components, which highlights the company's unwavering commitment to delivering superior quality products.

Testing 3D prints

Sintratec, a Swiss startup specializing in Selective Laser Sintering (SLS) 3D printers, has shared the process of testing their new machine, the Sintratec S2. The test demonstrates the strength of Sintratec's PA12 powder and the efficiency of the Sintratec S2 machine in producing durable prints. This article explores the rigorous testing processes and the resilience of components printed by the Sintratec S2.

In the comprehensive video produced by Sinatrec, we see Andi, a lead engineer at Sintratec, demonstrating the strength and durability of the parts produced by this new machine. The project involves designing a functional electric ducted fan (EDF) driven by an 800-watt RC brushless in-runner motor to see how much power the part could handle without being damaged.

Once the design was completed, the part was printed using Sintratec's strong PA12 material (EXTERNAL). The next step involved balancing the fan with lead balls around the rotation axis to prepare it for testing 3D prints (BAD). The EDF was then tied to a metal cord, mounted on a rail, and clamped to a table for the testing phase. With proper safety measures in place, the engine was started, and the speed was increased gradually.

However, the test was aborted at around a quarter to full speed due to concerns about powder emission from the front. Upon investigation, it was found that this resulted from a design flaw (GOOD) where a small inner area was not closed. The initial prototype had a hollow shell, which made the EDF too soft and pliable. The interior walls were reinforced with additional structures to address this, and the part was printed again.

Testing round two

In the subsequent test, the EDF was fixed onto a more stable workbench, and the power was increased once again. Although an imbalance in the spinner was noticed, it was removed, and the test continued. Smoke was added to visualize the airflow, and the peak power reached about 1,400 watts, a result considered impressive, especially given the motor's nominal power of 800 watts. The EDF sustained the test without any damage, showcasing the strength of Sintratec's PA12 powder and the efficiency of the Sintratec S2 machine in producing durable prints.

End Thoughts

Testing the durability of 3D printed parts is crucial for multiple reasons such as safety, material understanding, quality control, design optimization, regulatory compliance etc. Moreover, the durability of 3D-printed parts enhances the reputation of the products or services they're associated with.

The commendable performance of the Sintratec S2 system in the tests highlights Sintratec's commitment to giving customers the best and most reliable products, reaffirming its reputation in the world of 3D printing technology.