Filament Maker TWO: 3devo's Industrial Grade Extruder for R&D And Material Innovation

3devo's next-generation desktop extruder combines industrial precision with lab-scale simplicity enabling more controlled, higher-performance and data-driven 3D printing material workflows.

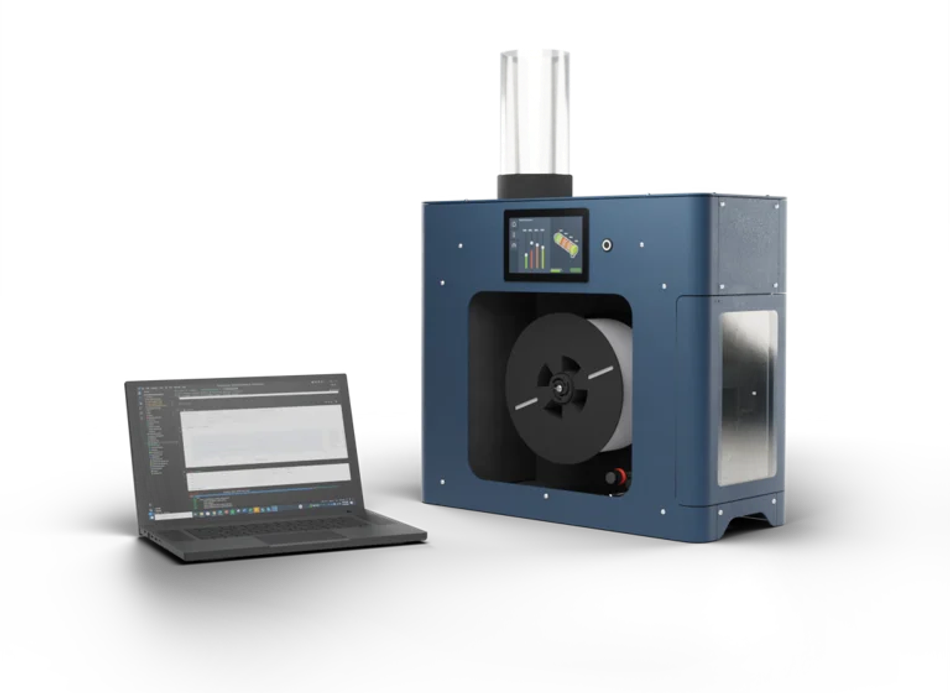

Filament Maker TWO – 3devo’s next-generation extrusion system, designed for R&D and industrial-grade applications.

Since it was founded in 2016, Netherlands-based 3devo has been driven by its goal of facilitating sustainable 3D printing innovation. Today, after almost a decade of operation, 3devo can count many successes on this front, having empowered users all over the globe to develop and manufacture their own thermoplastic filaments with its unique hardware solutions.

Among these solutions is the standard-setting Filament Maker ONE, used by over 1,800 customers, including leading institutions like MIT, Harvard, TU Delft, and companies such as Ford and Google. Feedback from these users has played a key role in shaping 3devo’s latest release: the Filament Maker TWO, an advanced extrusion system designed for material development labs, product designers, recycling initiatives, and print farms. It represents a significant step forward in precision, control, and productivity, making it well-suited for more demanding material workflows.

3devo’s latest product, the Filament Maker TWO, takes its offering to the next level in terms of performance and productivity.

The next generation

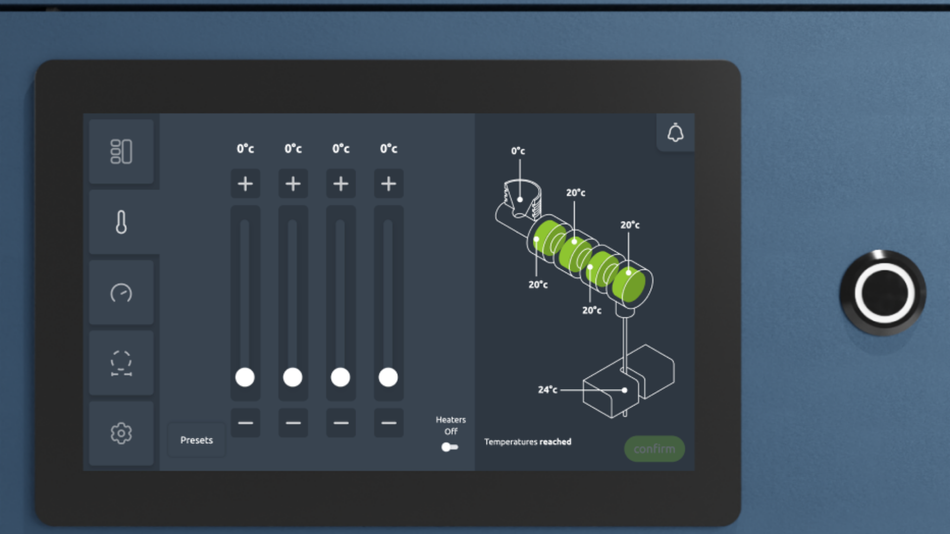

The Filament Maker TWO builds on the successes of the Filament Maker ONE and integrates several upgrades and new functionalities informed by customer feedback. These upgrades—which we’ll look at in more detail—enable Filament Maker TWO users to develop a wider range of 3D printing materials, including engineering-grade thermoplastics like PEEK, PEI, PEKK, traditionally challenging filaments like PA and TPU, as well as materials with additives and fillers like carbon fibers, ceramic and metal powders, and active pharmaceutical ingredients (APIs)—all while benefiting from a workflow that is both simpler and faster. Additionally, the new filament extruder can support not only R&D applications but also industrial-grade filament production, thanks to its plug-and-play nature and new features like its closed-loop smart system and advanced quality control.

Among the main upgrades integrated into the Filament Maker TWO are:

A modular split housing structure for easier cleaning, repairs, and maintenance.

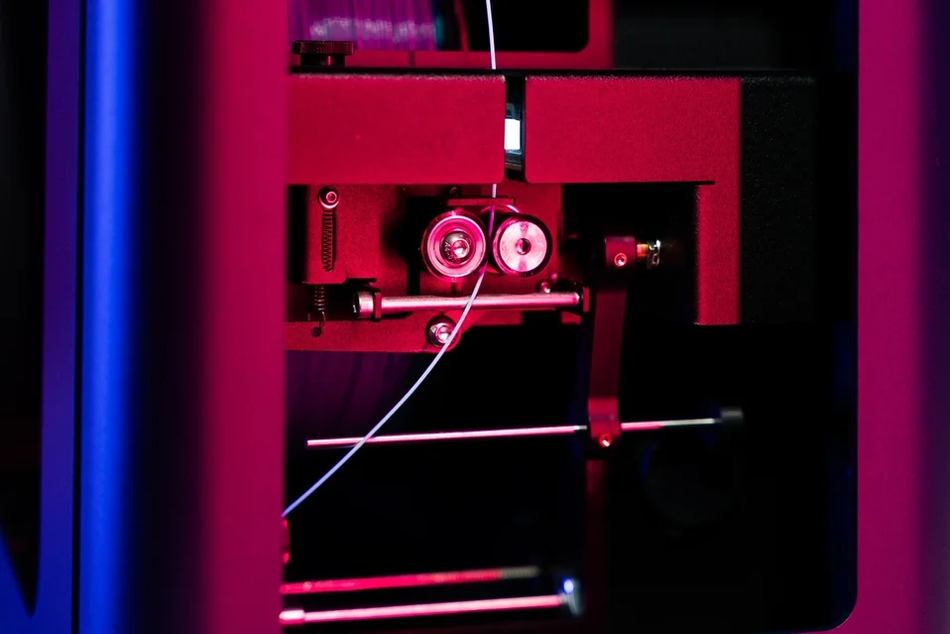

A more powerful (3x the torque) extruder drive system and extended screw for better extrusion and melt control.

A high-speed 3-axis filament sensor (with 10μm resolution) and infrared thermal camera for in-depth data monitoring and superior quality control.

Remote access and monitoring thanks to integration of open-source InfluxDB software.

Ethernet-enabled firmware updates for ongoing platform customization and improvements.

Intuitive touch-screen interface with real-time alerts, pre-set material profiles, and guided support to reduce learning curve.

Fully CE-certified with an interlock system for safety.

“Our Filament Maker TWO is ideal if you want to create custom materials with industrial-grade precision. There’s no other compact machine on the market that delivers such consistent, high-quality filament from advanced polymers and compounds,” says Dr. Janus Barnard, PhD Polymer Science . “Thanks to the 3-axis camera system and remote access, you can monitor quality in real time and even manage multiple units at once, making lab-scale filament production truly scalable.It essentially enables you to create a filament extrusion farm.”

From Lab Tests to Production Runs

With over 700 scientific publications citing its use, the Filament Maker ONE has been a trusted tool in R&D labs worldwide. Projects like the European Space Agency’s Spaceship EAC and Lattice Medical’s biodegradable implant development were powered by this original system—valued for its reliability and hands-on process control.

The Filament Maker TWO, for its part, is not only more than suitable for material development and testing applications, but also opens up more possibilities for scalable filament production. As we’ve touched upon already, features like remote control of the filament extruder, an intuitive interface, and built-in monitoring solutions (that ensure filament temperature and diameter are consistent) enable end users to reliably produce filament at scale.

Greater circularity

Another key priority for 3devo in developing the Filament Maker TWO was to make it easier for its customers to process recycled materials. End users interested in making the most out of 3D printing scrap or plastic waste by turning it into fresh 3D printing filament can do so through the combination of 3devo’s GP20 PlasticShredder, DW14 Desiccant Dryer and the Filament Makers.

In short, plastic waste goes into the two-in-one modular shredder and granulator, and the output—a homogenous regrind of whatever thermoplastic was processed—is dried in the dryer and is then suitable as input material for the filament extruder. This means that users can bring their circular material production in-house and create functional 3D printer filament from plastic waste. Or, in the case of Lattice Medical, which is developing an implant made from a costly bioabsorbable polymer (€5000 per kilogram), the ability to reprocess 3D printer scrap or test parts and turn them into fresh filament is absolutely essential to the development work they do.

Ultimately, 3devo’s latest solution has taken into account much of the feedback the Dutch company has received over the years, delivering a new and improved machine for making high-quality filament. With its sleek, compact profile, the Filament Maker TWO is ushering in a new era of efficiency, sustainability, and autonomy for a broad range of end users. The hardware solution, and 3devo’s other products are all available through its global reseller network. Moreover, through their partnership framework, customers can not only benefit from the quality of the hardware, but also leverage 3devo’s deep material expertise to develop, test, and validate new formulations.