Streamlining IoT Project Development

How plug-and-play IoT sensor platforms can speed up product development

Introduction

The Internet of Things (IoT) market has experienced significant growth in the last few years, with a global volume of $384.70 billion in 2021 and projections reaching $2,465.26 billion in 20291. As this market expands, companies are struggling to develop and deploy innovative solutions to stay competitive. However, the time from the proof of concept to having a fully developed IoT product is critical and can be a major challenge for engineering teams.

Plug-and-play IoT solutions help engineers to reduce proof of concept time and enable faster insights and user feedback at a lower cost. This article explores the benefits of plug-and-play IoT solutions. Furthermore, it highlights the technical features and applications of the Infineon XENSIV™ Connected Sensor Kit (CSK), a powerful tool designed to accelerate IoT project development.

Speeding Up IoT Development with Plug-And-Play Solutions

Setting up sensors and wireless connections and analyzing the data can be challenging and time-consuming, especially if you are starting a new project. The IoT product development process delay may seriously impact your project's validation.

Plug-and-play IoT platforms are a new approach to building IoT solutions requiring almost no configuration. The plug-and-play IoT solutions combine various sensors with an MCU and wireless connectivity. In addition, hands-on user guides enable engineers to test and validate IoT solutions in just a few minutes without additional code development. Typically, the only configuration before testing, the Wi-Fi setup, will be performed through a graphical interface. As a result of plug-and-play IoT adoption, developers and engineers can focus on creating IoT products that bring value to the users, making their lives easier, thanks to an easier IoT prototyping process.

How Infineon’s CSK Can Enhance IoT Project Development

Infineon’s XENSIV™ connected sensor kit Overview

Infineon’s XENSIV™ connected sensor kit (CSK) is part of an all-in-one IoT development ecosystem with generic sensors, libraries, and sample application code for sensor and connectivity use cases. It makes the development of new prototypes more straightforward by taking advantage of Infineon sensors. The CSK removes the complexity of prototyping a sensor board Thus, it is a strong development option for customers in the IoT space looking to rapidly design, develop and manufacture products to test sensor-driven IoT products.

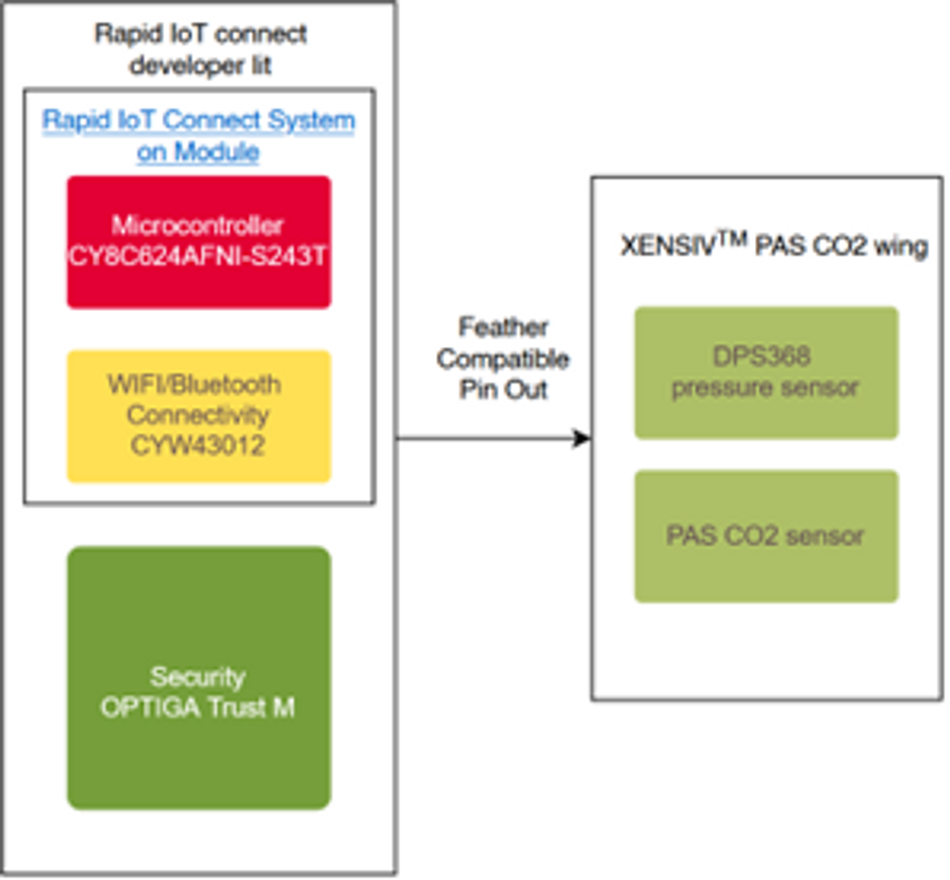

The XENSIV™ connected sensor kit enables low-power consumption and wireless communication. All XENSIV™ CSK models use the PSoC™ 62 low-power dual-core microcontroller to manage sensors and data transmission. It has six power modes for fine-grained power management, consuming 7 μA in the deep sleep mode and 22 μA/MHz in active power mode. Regarding connectivity, the kit uses low-power Wi-Fi (dual band – 2.4 and 5 GHz) and Bluetooth 5.0 combo. The XENSIV™ CSK also has a security layer thanks to Infineon’s OPTIGA™ Trust M, which ensures mutual authentication, secured communication, and data-store protection. In addition, it is FCC and CE pre-certified.

The XENSIV™ connected sensor kit can be used on applications requiring measurement of temperature, pressure, and CO2 levels or motion monitoring. These measurements are based on XENSIV™ 60 GHz radar, PAS CO2, and DPS368 pressure sensors, which results in a compact system with low power consumption. For example, the DPS368 consumes an average of 1.7 μA while measuring pressure with a sampling rate of 1Hz, and its package dimensions are 2.0 x 2.5 x 1.1 mm3.

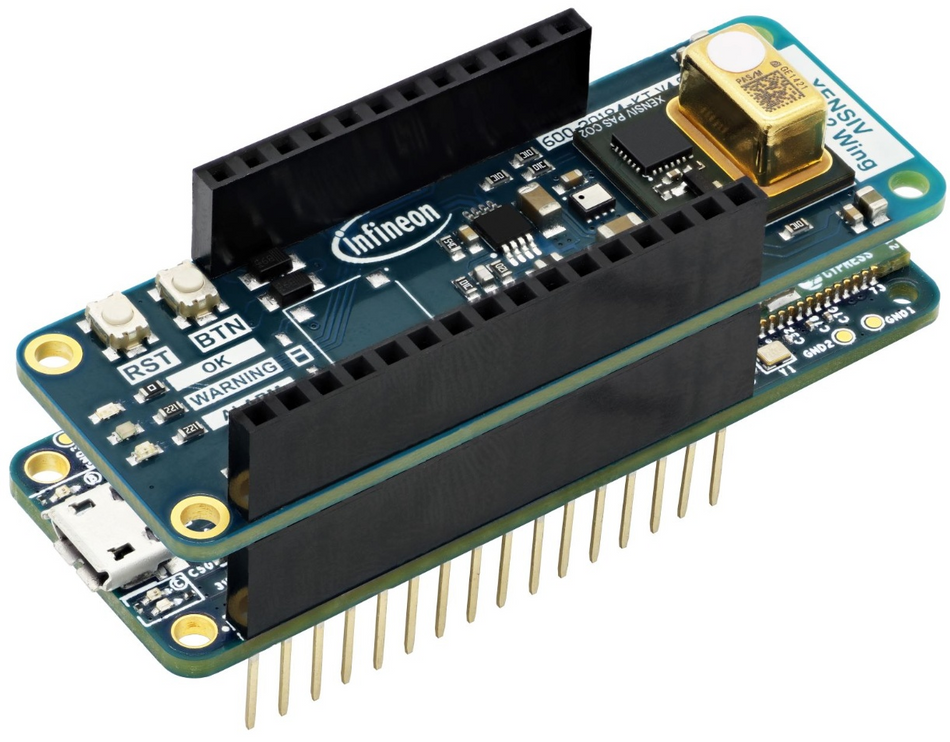

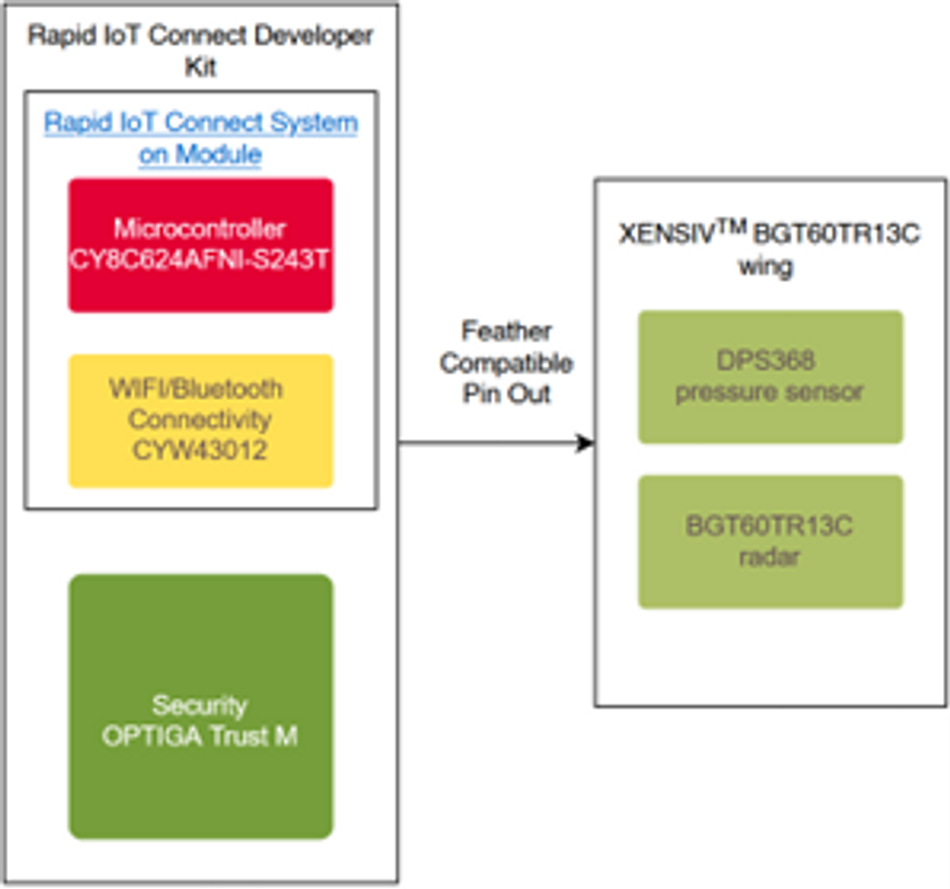

There are two models for Infineon’s XENSIV™ CSK, the CSK PASCO2, and the CSK BGT60TR13C. They are feather compatible, with a baseboard (Rapid IoT Connected Developer Kit) containing the processor and connectivity sensors. The BGT60TR13C was designed to support presence detection projects using a radar and provide temperature and pressure measurements. The KIT CSK PASCO2 also includes these measures, but instead of a radar, it comes with a PAS CO2 sensor, ideal for air quality monitoring applications.

As a plug-and-play solution, Infineon’s XENSIV™ connected sensor kit should provide users an easy and fast start-up experience. It is achieved through the ModusToolbox™ software ecosystem developed by Infineon. The seamless integration to ModusToolbox™ empowers developers with application code examples and sensor drivers for faster go-to-market. In addition, developers can access all Infineon communities and materials and the development tools supporting Windows, Linux, and macOS to create new embedded applications.

Running an Application with Infineon’s XENSIV™ Connected Sensor Kit

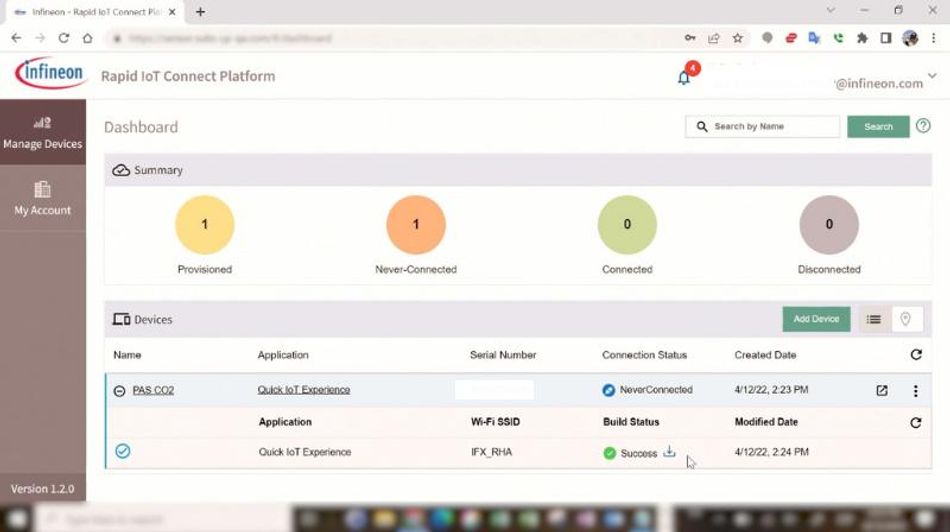

Infineon provides quick guides for KIT CSK BGT60TR13C and KIT CSK PASCO2. These getting started guides show the fast way to get your CSK up and running. The first thing to do is to connect the XENSIV™ connected sensor kit to your computer using a USB cable and access the Rapid IoT Connect Platform. Here you can register your kit and set a username and a password to get started.

After logging in, you will add your device using its serial number. The system will guide you to download and program your development kit with a pre-built example application and all the required credentials to connect to the cloud securely. At this point, you must provide access information to a Wi-Fi network information so the kit can connect to the cloud. After these steps, the cloud will build a project for you, which can be accessed at the devices tab on the Rapid IoT Connect Platform homepage.

With the project successfully built, it is time to download the files and transfer them to the kit. After downloading and extracting the compressed folder, you will find all files required to program the XENSIV™ connected sensor kit. At this point, the only thing that you need to do is run the program_kit file. It will erase everything from the kit’s memory, install the program, and set up the Wi-Fi connection.

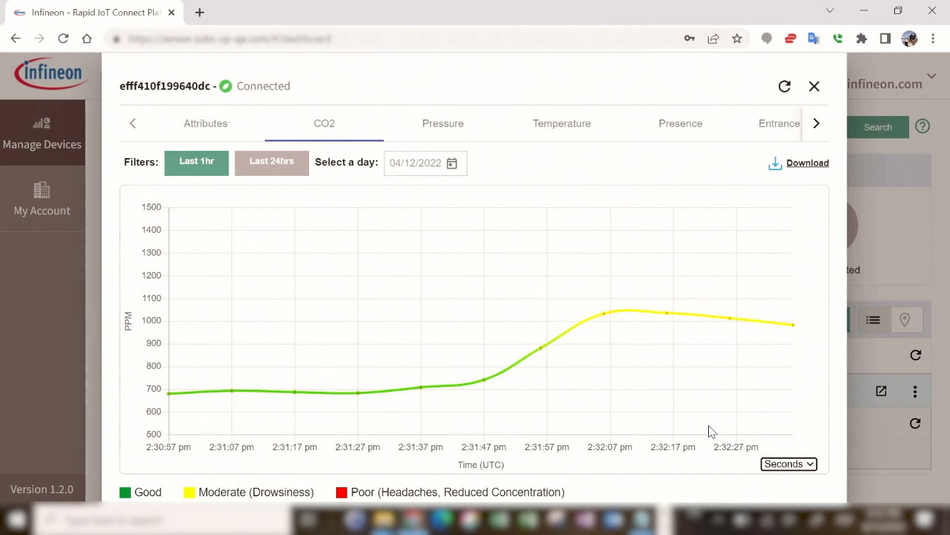

Next, the XENSIV™ connected sensor kit will find and connect to the previously defined network. The cloud application will modify the connection status to connected once the connection with the board is performed. Now you can access the board measurements and configure it through the cloud, adjusting the measurement frequency, for example.

Infineon’s XENSIV™ Connected Sensor Kit Use Cases

Infineon offers a radar-based presence detection example to detect human presence within a configured distance. Applying these systems to smart building projects can significantly improve energy efficiency by activating devices, such as lighting, heating, cooling, and ventilation, only when people are present. The XENSIV™ KIT CSK BGT60TR13C provides the ability to detect not only macro movements but also micro-movements, such as typing on a keyboard or chest movements while breathing. Therefore, you can use a XENSIV™ KIT CSK BGT60TR13C in each room to increase the assertiveness regarding device control, by providing more data about people's presence in each room. The example provides a great introduction to the capabilities of 60 GHz Radar.

Air quality monitoring systems are one application of the XENSIV™ KIT CSK PASCO2. Monitoring indoor CO2 levels is crucial for human health, safety, and building energy efficiency. Thanks to its easy connection, several XENSIV™ KIT CSK PASCO2 can be used to create a network of sensors, covering entire buildings and providing precise data regarding CO2 levels. The acquired data can support the controlling system by regulating the necessary airflow inside the building. This solution ensures air quality and energy efficiency since the ventilation system will only operate when CO2 levels are above acceptable limits.

Conclusion

Plug-and-play IoT solutions can help reduce the proof of concept time, enable faster insights, and provide valuable user feedback at a lower cost. Infineon’s XENSIV™ connected sensor kit solves the three significant challenges of any IoT device’s development and deployment, combining sensors, data processing, and connectivity to the cloud. The XENSIV™ connected sensor kit's technical features make it ideal for applications that require low power consumption and temperature, pressure, and CO2 level measurements or motion monitoring. For those in the IoT sector, the connected sensor kit is a crucial instrument to enable engineers and developers to focus on the data that matters most to their final product.

About the sponsor: Infineon Technologies

Infineon Technologies AG is a world leader in semiconductor solutions that make life easier, safer and greener. Microelectronics from Infineon are the key to a better future. With around 50,280 employees worldwide, Infineon generated revenue of about €11.1 billion in the 2021 fiscal year (ending 30 September) and is one of the ten largest semiconductor companies worldwide. To learn more click here.

References

[1] Fortune Business Insights, “Internet of Things (IoT) Market Size, Share & COVID-19 Impact Analysis, By Component (Platform, Solution & Services), By End-use Industry (BFSI, Retail, Government, Healthcare, Manufacturing, Agriculture, Sustainable Energy, Transportation, IT & Telecom, and Others), and Regional Forecast, 2022-2029”.

[2] Zenatix, “What Plug and Play Mean for IoT?”

[3] Microsoft, “What is IoT Plug and Play?”

[4] Infineon, “From Presence Detection to Vital Sensing: How to Develop Your IoT Solution Quickly”

[5] Bernd Kohler, “How Radar Sensors Significantly Improve the Energy Efficiency of the Smart Home”, EE|Times Europe.