AROL Tops Capping Machines with Smart Maintenance

Seeking a way to make their high-speed production equipment even more reliable and productive, AROL recently decided to develop an innovative solution to enable data monitoring and predictive maintenance, upgrading their offering with an Industry 4.0 approach.

AROL's advanced capping machine

Capping lines in modern factories are machines of incredible speed and precision, capable of installing thousands of caps on bottles and containers every hour. Based in Canelli, Italy, AROL is a leading provider of innovative and custom capping and closure system machines, with over 25,000 pieces of equipment currently installed around the world. With production lines processing up to 100,000 bottles per hour, maintaining their machines’ speed and ongoing reliability is critical to operations. In other words, any outage or unplanned downtime would be detrimental to meeting production quotas and costly to their clients.

Adding Brains to Speed for Improved Productivity

To support diagnostic, prognostic and predictive maintenance, they decided to draw on their experience to develop a smart solution able to gather data from industrial equipment and the surrounding environment, creating a machine monitoring system based on remote wireless sensors that could be powered by battery or 24 V.

The project faced specific challenges in the fact sensor nodes had to be mounted in rotating capping turrets, fitting in a small space and yet always remaining connected to a communication unit at the base of the line. What’s more, they had to perform part of the data processing on the edge, in order to not overload the central system. And of course, the upgraded capping machine had to be made smart without costing sensibly more.

An Innovative System for Predictive Maintenance

To accelerate the process, AROL relied on a cost-effective, open-source system based on a combination of Arduino Pro’s Nicla Sense ME and Portenta Machine Control. This allowed their engineers to work with advanced sensors and high computational power, while still leveraging the ease of off-the-shelf components. With the support of a problem-solving and forward-thinking partner, the company quickly developed and tested a working solution: “The Arduino team was very proactive in understanding our requirements and providing a business-oriented solution with a customer-focus approach,” commented Denis Ruffino, R&D technical director at AROL.

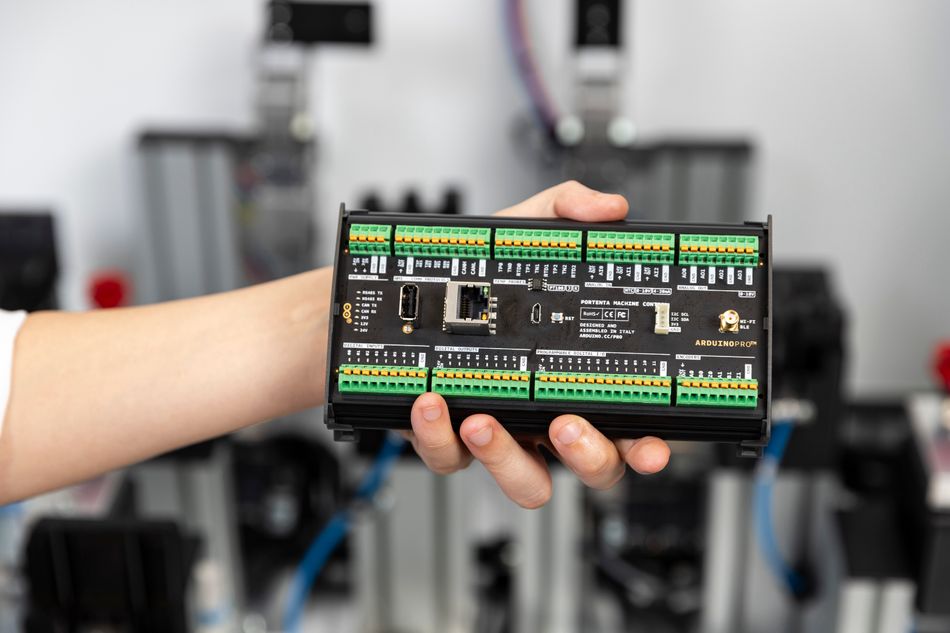

AROL fitted each of the 15 capping turrets in one of their machines with a compact Nicla Sense ME, providing vibration and temperature detection thanks to state-of-the-art, onboard Bosch Sensortec sensors – as well as the computational power to process part of the data directly at the level of the sensing nodes. At the base of the machine, one Portenta Machine Control was easily mounted on DIN rail to concentrate communication with all the sensors via Bluetooth®.

Having chosen an open-source solution, AROL is poised to scale up the idea with limited refactoring – and further upgrade their advanced capping machines, raising the bar of innovation for their industry.