Be the first to know.

Get our arduino weekly email digest.

Tagged with

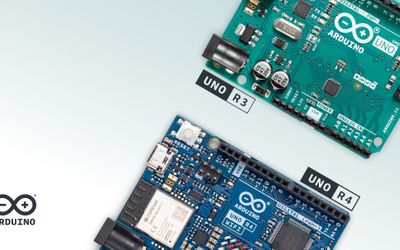

arduino

ORGANIZATIONS. SHAPING THE INDUSTRY.

Arduino Pro

Electrical & Electronic Manufacturing

Arduino is a global leader in open-source hardware and software, with over ...

7 Posts