3D Printing Drives Innovation in Packaging Industry

Introducing the third article in a new series. 3D printing is helping to usher the trillion-dollar packaging industry into the future.

Transforming Production: The Unseen Power of 3D Printing

With the playbook “Transforming Production - The Unseen Power of 3D Printing”, manufacturers and engineers can draw inspiration from experts who are already using 3D printing in their production processes. This free PDF provides high-value application suggestions and detailed case studies of what you can achieve using FDM (Fused Deposition Modeling) 3D printing technology.

Fill in this short form to get your copy directly to your inbox.

Introducing the second article in a new series, making clear the impact of additive manufacturing on Manufacturing, Transport, Packaging, and STEAM. In this article, we're zooming in on Packaging.

The Impact of 3D Printing

Worth over one trillion dollars in 2023, the global packaging industry is a major industrial segment, responsible for making everything from shampoo bottles to the tins that preserve food. And while we take most packaging for granted, quickly discarding it to get the product inside, the industry and its products have evolved tremendously over the years and have been shaped by new ideas and innovations.

Consider the early days of packaging, which used natural resources like wood, leaves, and clay to create containers for food and other goods. Fast forward to the early 19th century, and we see the advent of tinned canning revolutionize food preservation and transport. The next big innovation in the 20th century was plastic, which truly changed the game, as it could be formed into container shapes of various stiffnesses, flexible films, and more.

Today, 3D printing is at the frontier of packaging innovation. The technology, which can produce complex products on demand from a wide range of different materials, is enabling players in the packaging space to realize cutting-edge designs, explore customization, and increase the efficiency of production lines.

In this article—the third in an UltiMaker-supported series exploring the impacts of additive manufacturing in Manufacturing, Packaging, Transport, and STEAM—we’re looking at the various ways that 3D printing is helping to usher the trillion-dollar industry into the future, with a particular emphasis on innovation, production agility, and sustainability.

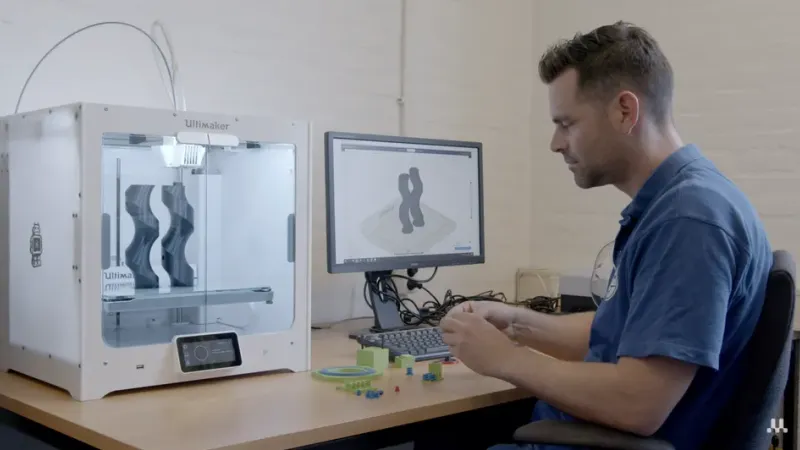

3D Printing for Design and Prototyping

In packaging, as in other industries, 3D printing is now widely used for product design and prototyping. There are several reasons for this. For one, unlike traditional manufacturing processes like injection molding, 3D printing is not bound by the same economies of scale. This means it is cost effective to 3D print a single prototype or multiple different prototypes in a single batch. On top of that, 3D printing has enabled packaging designers and manufacturers to dramatically speed up the product development cycles and time to market. This is because packaging designers can easily print a physical prototype based on a CAD model, test the design, tweak it, and ultimately validate it without having to work with external production partners and without having to invest in costly tooling. The technology also creates wholly new design opportunities for packaging, which can enhance a package’s function, aesthetics, and marketability.

L’Oréal, the world's largest cosmetics company, has successfully been using 3D printing to this end for years now. The company, which printed 14,000 packaging prototypes in 2017 alone, has accelerated its prototyping process from upwards of six months to mere days by using UltiMaker 3D printers to validate new designs, and rapidly iterate prototypes and packaging injection molds. The company says: “3D printing lets us skip steps within the design process. By bringing the technology in-house, we can dramatically reduce the time it takes to produce packaging prototypes. What’s more, by going from concept to prototype more quickly, we drastically reduce time to market, too. In fact, before the 3D printing boom, development for a product launch could take anything up to 18 months. Today, we can validate new designs in just a day or two.” The ability to accelerate packaging design turnaround times a huge boon in the consumer goods space, where staying ahead of the competition and getting products to market in a timely way is key.

Beyond prototyping, 3D printing is also increasingly being adopted to create packaging designs that would be impossible to achieve using other production methods. This use case for additive technologies is particularly prevalent in the production of luxury packaging, where exclusive, state-of-the-art designs are a priority. In late 2020, for example, L’Oréal and avant-garde luxury fashion house Viktor & Rolf collaborated to design an “haute couture edition” of L’Oréal’s Flowerbomb fragrance. 3D printing was used at various stages of the packaging design process, from prototyping to final product. The elegant and intricate perfume packaging is limited edition: 15 copies were 3D printed, hand polished and assembled, and dipped in rose gold. For consumers, the printed design brings something new to the table, taking the original product to the next level.

L’Oréal isn’t the only company to reap the benefits of using additive manufacturing for packaging design and product development. PepsiCo and Marvel Studios turned to 3D printing to create limited edition Black Panther masks for the film’s promotional canned beverages. The 3D printed can masks were produced in a limited run, which would not have been financially viable using injection molding. The packaging also took advantage of the design freedom afforded by 3D printing, resulting in a unique product for consumers and an effective marketing strategy for the partners.

3D Printing for Manufacturing and Supply Chain Efficiency

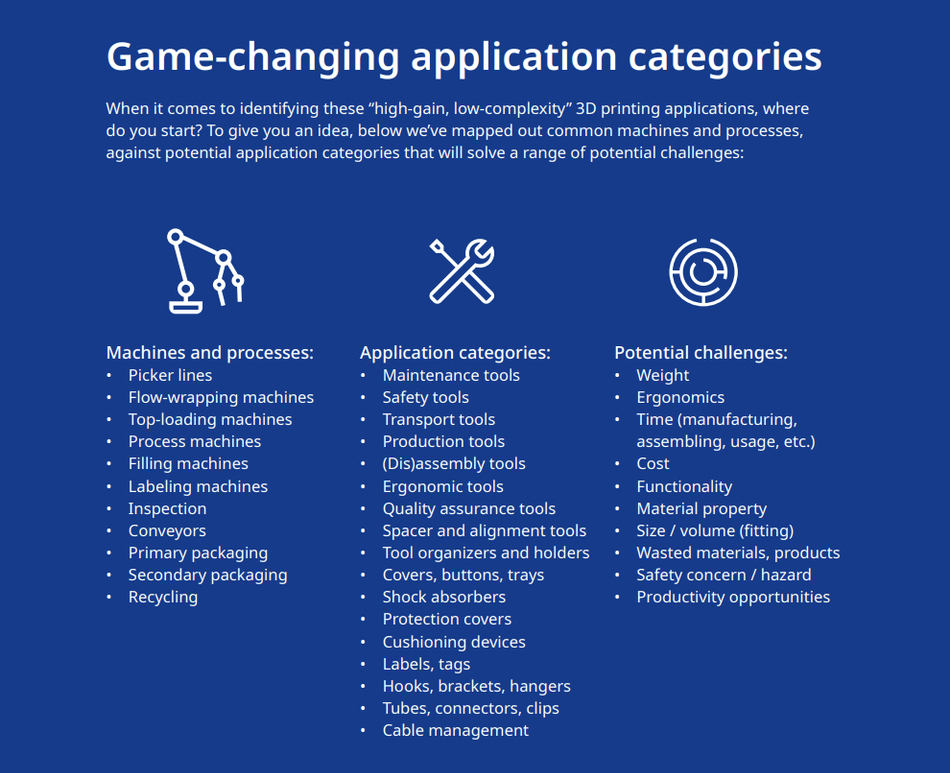

3D printing also has a role to play after product development: packaging manufacturers are enthusiastically adopting the technology to enhance their production lines and achieve greater resiliency against supply chain weaknesses. With in-house 3D printing, it’s possible to design and rapidly create various components that support existing mass production lines, including custom grippers, tools, assembly fixtures, and replacement parts, to name but a few. This capability is further reinforced by the ever-growing range of available materials for FFF 3D printing. Thermoplastic filaments engineered for wear resistance and strength meet the requirements of production lines, while increasing availability of certified food-safe plastics are creating even more opportunities for packaging companies working in the food and beverage industries.

There are countless applications for FFF 3D printing in packaging production lines that can enhance efficiency. What the best of them have in common is that they are both high gain and low complexity. A high-gain application is defined as one that will help to maintain productivity, and will enhance operator safety while simplifying their job. A low-complexity application is one that is characterized by a simple geometry (i.e. easy to design and optimize for AM), that does not have to meet safety requirements (minimizing validation time), and which is used in a normal production environment (for greater material options). Applications that meet these criteria typically result in a rapid return on investment (ROI). Below are some examples of effective 3D printing applications in packaging manufacturing.

Trivium infeed worm

Trivium, a global company specializing in sustainable metal packaging, has integrated 3D printing in its workflow to keep its production lines running smoothly. UltiMaker’s 3D printing platform has proven to be a cost-effective solution for making replacement components, such as an infeed worm used in its conveyor belt system. These parts function as precision-engineered timing screws and are essential in conveyor systems. In some cases, conventionally manufactured infeed worms can cost as much as EUR 10,000. At Trivium, the company turned to UltiMaker 3D printing when an original infeed worm wore out. Using UltiMaker’s industrial-ready ecosystem, the team remodeled the component, sliced it using Cura software, and printed it in two pieces using a carbon fiber-reinforced nylon. This material, which offers enhanced toughness compared to non-composite nylon, was viable thanks to UltiMaker’s open materials platform, which enables the use of third party materials, including fiber-filled filaments.

Now assembled, the part fits seamlessly into the conveyor system, keeping the legacy system up and running. In the end, by printing the parts on-demand, the company was able to replace the part at a minimal cost and keep its production line active.

Heineken fixtures and safety equipment

Globally recognized brewer Heineken has also turned to 3D printing to keep its manufacturing lines running smoothly. At its facility in Seville, Spain, engineers regularly design and 3D print fixtures, machine parts, and safety equipment on demand. In some cases, the engineers have updated the design of replacement parts for optimized performance, and in others wholly new solutions have been created to boost operator safety. Using 3D printing has not only increased the facility’s safety and production uptime, Heineken has also saved 80% in production costs for the parts they print in-house and achieved 70-90% faster delivery times (compared to outsourcing). Read more about Heinken's use of 3D printing here.

Lonypack food-processing parts

Lonypack Global, a Spanish company specializing in processing and packaging cured meats and dairy, has also optimized its production line with the help of UltiMaker 3D printing. One of the company’s top priorities was to rapidly create cost-efficient replacement parts for its boning, slicing, and packaging lines that met food safety requirements. Due to its precision and reliability, the UltiMaker S5 was ultimately selected by Lonypack in combination with Kimya’s PETG-S, a blue-colored filament certified safe for food contact. To date, the food processing company has successfully 3D printed parts like cutting edges, picker combs, turning mechanisms, cutters, and robotic arm sprockets, all while reducing delivery times and costs by 70%.

This is but a small sample of the companies using 3D printing in their packaging lines, and a fraction of the applications now in use. Other positive impacts of additive manufacturing in this context include being able to access a digital inventory of parts that can be accessed as needed. Gerhard Schubert GmbH, a leader in packaging machines, has developed a digital warehouse of printable tools designed for additive manufacturing (with overhangs of max 45 degrees, droplet shaped holes, minimal supports) that its clients can easily download and print right in their own facility using an UltiMaker 3D printer. Having access to such a digital inventory enables packaging facilities to minimize warehousing and inventory costs associated with storing spare machine parts. Furthermore, the ability to print parts on-demand (and on site) helps establish greater supply chain resilience, since packaging companies are less reliant on external suppliers for essential production line components.

Opportunities for Future Innovation

Advances in packaging are ever evolving, and it’s becoming clear that 3D printing has a role to play in the industry’s latest trends. Chief among these trends is sustainability. In the packaging world, sustainability is on everyone’s minds, as consumers increasingly demand more environmentally friendly products and packaging companies seek to address those demands. In fact, McKinsey names sustainability as one of the top priorities for packaging companies as they invest in new solutions.

3D printing can give the packaging industry a sustainable edge in a couple ways. On the one hand, the 3D printing industry is bringing to market more and more materials made from recycled and bio-based materials. Whether used for a prototype or final product, these materials rank higher on the eco-scale compared to many single use packaging plastics. By enabling in-house production, 3D printing can also contribute to simpler supply chains and fewer logistics. This ultimately translates to fewer transport emissions for the shipping of replacement parts.

Advances in FFF material availability will also open up new opportunities for 3D printing in the packaging space. For example, as more materials are certified for food contact, packaging companies in the beverage and food industries will be able to implement 3D printed components for a wider range of use cases. Moreover, as the use of 3D printing materials increases, the cost of filaments will become more accessible, thus enabling even greater adoption. This, paired with UltiMaker’s cost- and user-accessible 3D printing ecosystem, will make it possible for all manufacturing facilities to seamlessly integrate additive manufacturing into their production lines.

Last but not least, 3D printing is well positioned to open the doors for personalized packaging. Packaging manufacturers can take advantage of the technology’s ability to print multiple different designs in a single build to create bespoke packaging for custom or luxury products. Production lines can also be adapted for increasing product customization using 3D printed grippers, fixtures, and more. In the same vein, operator tools in production lines can be customized to the operator for optimized ergonomics and efficiency.

Up next…

Though you might hear less about 3D printing in the packaging industry than say in aerospace or automotive, there are very real benefits to adopting the technology in this context, and huge potential for it down the line. Not only does 3D printing dramatically accelerate the time to market for packaging products through rapid prototyping, it is being used to create innovative packaging designs that captivate consumers.

3D printing is arguably having an even greater impact on the production front: by reducing machine downtimes and streamlining maintenance through in-situ production of space parts, 3D printing is dramatically enhancing the efficiency, productivity, and automation of packaging manufacturing lines and helping manufacturers to overcome supply chain hurdles. In the next installment in this series, we’ll be shifting gears to look at the transportation industry, exploring how additive processes are advancing the production of cars, planes, trains, and more.

References

[1] Market Size Of Packaging Industry [Internet]. Mordor Intelligence. 2023. Available from: https://www.mordorintelligence.com/industry-reports/global-packaging-market/market-size

[2] Transformative beauty: L’Oréal prepares for the future with 3D printing [Internet]. UltiMaker. October 2021. Available from: https://ultimaker.com/learn/transformative-beauty-loreal-prepares-for-the-future-with-3d-printing/

[3] Beauty In The Fast Lane: How 3D Printing Is Transforming The Way L’Oréal Works. Beauty Tomorrow. December 2018. Available from: https://beautytmr.com/loreal3dprinting-19cdc3229a63

[4] Flowerbomb By Viktor&Rolf: 3D Printing To Create The Exceptional [Internet]. L’Oréal. December 2020. Available from: https://www.loreal.com/en/news/brands/flowerbomb-3d-vr/

[5] PepsiCo R&D Team Elevates Packaging Design with 3D Printing [Internet]. ProtoLabs. May 2018. Available from: https://www.protolabs.com/resources/success-stories/pepsico/

[6] Trivium: 3D printing replacement parts for automated packaging lines [Internet]. UltiMaker. February 2021. Available from: https://ultimaker.com/learn/trivium-3d-printing-replacement-parts-for-automated-packaging-lines/

[7] Heineken taps Ultimaker for 3D printed functional parts and tooling for use on the manufacturing line [Internet]. UltiMaker. May 2019. Available from: https://press.ultimaker.com/heineken-taps-ultimaker-for-3d-printed-functional-parts-and-tooling-for-use-on-the-manufacturing-line/

[8] Lonypack: Optimizing food packaging with 3D printing [Internet]. UltiMaker. May 2023. Available from: https://ultimaker.com/learn/lonypack-optimizing-food-packaging-with-3d-printing/

[9] Schubert: A digital warehouse for on-demand manufacturing [Internet]. UltiMaker. November 2019. Available from: https://ultimaker.com/learn/schubert-a-digital-warehouse-for-on-demand-manufacturing/

[10] 2022 and beyond for the packaging industry’s CEOs: The priorities for resilience [Internet]. McKinsey & Company. March 2022. Available from: https://www.mckinsey.com/industries/paper-forest-products-and-packaging/our-insights/2022-and-beyond-for-the-packaging-industrys-ceos-the-priorities-for-resilience

[11] Tracey CT, Predeina AL, Krivoshapkina EF, Kumacheva E. A 3D printing approach to intelligent food packaging. Trends in Food Science & Technology. September 1 2022;127:87-98. Available from: https://www.sciencedirect.com/science/article/abs/pii/S0924224422001637