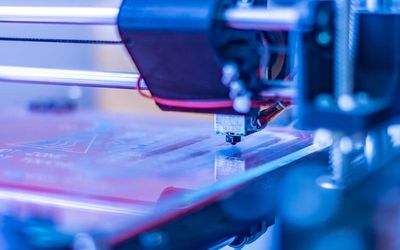

The rapid evolution of 3D printing technology has made it faster, more automated and capable of greater production volumes. Developments have reached a point where the technology offers manufacturers significant production value. It means manufacturing costs can be significantly reduced in all aspects of manufacturing, all the way from R&D to actual production.

Tagged with

3D Printing

ORGANIZATIONS. SHAPING THE INDUSTRY.

The Next Byte

Entertainment

The Next Byte Podcast is hosted by two young engineers - Daniel and Farbod - who select the most interesting tech/engineering cont...

165 Posts

View more

Latest Posts

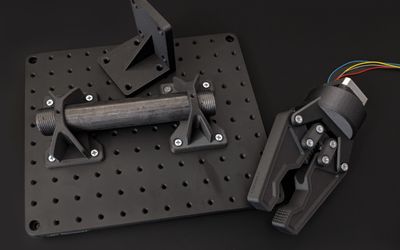

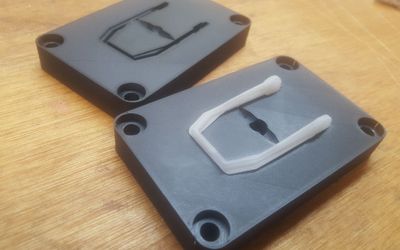

Composites are a category of materials that encompass a large number of different properties and use cases. And even within carbon fiber composites, you can get vastly different results depending on the specific material you choose. In this article, we will take a look at the different UltiMaker carbon fiber composites available and help you decide which one is best for your needs. First, let’s look at which characteristics all the UltiMaker carbon fiber materials share.

It’s hard to believe that 3D printing has only been around since the 1980s. This technique, also called additive manufacturing, has proved so immensely useful that it’s evolving very quickly. The process was originally devised to make prototypes for one-off or small-batch parts. Materials were added progressively to build up a solid object, based on 3D digital models. It was much more cost-efficient than cutting source materials down, as no waste was apparently produced.

Carbon fiber is one of the most powerful materials for anyone trying to get the most out of 3D printing. But when should you use it, and what applications can you use it for? Let’s delve into these questions and discover why 3D printed carbon fiber composites are more accessible and versatile than ever before.

Monitoring and automation systems are enabling factors to enhance productivity of innovative production technologies such as additive manufacturing. In this scenario, Caracol developed the project RAMICoS - Intelligent Control System for Robotic Large Scale Additive Manufacturing System, together with MADE Competence Center and Politecnico di Milano.