Leveraging cutting-edge inertial sensors to enable true autonomy in extreme conditions

Extreme temperatures, vibrations, and electromagnetic interference can disrupt sensor performance. The Xsens Sirius Series offers a solution with its accuracy and reliability, even in the most demanding conditions.

Introduction

The industrial automation market is experiencing rapid growth. Valued at $188 billion in 2023, it is expected to reach $368 billion by 2031.1 This growth reflects the increasing reliance on automation to enhance precision and efficiency in industrial processes.

As automation is embraced by various industries, autonomous systems that can function reliably in harsh conditions are becoming essential. While operating in extreme conditions, sensors of autonomous systems need to perform in extreme temperatures, humidity, vibrations, shocks, magnetic interferences, and more.

To address these challenges, Xsens has introduced the Sirius Series, a family of inertial measurement units (IMUs) designed to perform in extreme conditions. Comprising of Sirius IMU, Sirius VRU, and Sirius AHRS, this product line delivers true autonomy in marine, mobile robotics, agriculture, and mining applications. The article will explore how the Xsens Sirius Series performs reliably where traditional sensors struggle.

What sets Xsens Sirius Series apart from conventional solutions?

Accurate and reliable sensor data is vital for the dependable operation of autonomous systems. While they function well in normal environments, their shortcomings are exposed in challenging conditions.2 These drawbacks are as follows:

Limited Weather Resistance

Traditional sensors struggle in harsh environments with extreme cold, salt exposure, high humidity, and dust. These conditions speed up wear and lead to frequent failures, driving up maintenance costs and reducing system reliability. Over time, this makes long-term operations more challenging and less efficient.

Prone to Vibration Interference

In industrial settings with heavy machinery, as well as offroading in rough terrain for agriculture and mining, traditional sensors often experience performance degradation. The constant vibrations from large equipment add noise and errors to the sensor data. As a result, orientation data becomes unreliable, which compromises the performance of autonomous systems.

Complex Integration

Integrating new sensors into legacy systems can be a challenging task. It typically requires significant software and hardware adjustments to ensure proper functionality. This often results in costly and time-consuming setup processes to integrate sensors into established workflows.

How The Xsens Sirius Series Gets the Job Done

The Xsens Sirius Series is engineered to address the challenges posed by extreme weather in industrial automation. The company relies on cutting-edge technology and design innovations to deliver performance where traditional sensors fall short.

Unlike technologies that rely on external signals, Xsens' Sirius Series uses internal components such as accelerometers, gyroscopes, and magnetometer to track motion and compute orientation (roll, pitch, and yaw). By processing acceleration, angular velocity, and magnetic field data through advanced sensor fusion algorithms, it accurately determines the device’s position and movement.

At the heart of the Xsens Sirius Series is its dual-processor design, which improves accuracy by efficiently handling sensor fusion, noise filtering, and real-time processing. This enables faster processing, lower latency, and power efficiency, making the IMU well-suited for dynamic real-time applications. Additionally, the rugged housing protects from extreme temperatures, high humidity, and saltwater.

Key features and innovations in Xsens Sirius Series

Precise 3D Orientation Data

The Xsens Sirius Series produces highly accurate 3D orientation data using several advanced technologies. These units feature a precise accelerometer, gyroscope, and magnetometer. The sensor fusion algorithm provides superior orientation estimates. Each sensor is tested in-house and factory calibrated. Analog filtering in the signal chain removes unwanted noise and shocks. This makes the Xsense Sirius sensors ideal for stabilization, motion tracking, and positioning.

Built for Extreme Conditions

The Xsens Sirius Series is engineered to withstand harsh environments. It meets MIL-STD-202 durability standards set by the U.S. Department of Defense, ensuring reliable performance under vibrations, shocks, and extreme temperatures. The sensors also carry an IP68 rating, which indicates they are dustproof and can withstand water immersion. The Xsens Sirius Series operates in temperatures from -40 to +85°C. It works reliably in any region from freezing Arctic conditions to scorching desert heat. This level of protection enhances longevity and minimizes maintenance costs in the long run.

Resistance to Magnetic Disturbances

Environments with a strong electromagnetic field or large ore deposits can throw off the reliability of 3D orientation sensors. The Xsens Sirius Series is designed to resist magnetic disturbances owing to its advanced magnetic models. Using specialized calibration techniques, filtering algorithms, and adaptive profiles, these sensors maintain reliable orientation data even in environments with magnetic interference.

Easy Integration with Existing Systems

Ease of integration is another standout feature of the Xsens Sirius Series. It features a plug-and-play software suite, a user-friendly software development kit (SDK), and APIs along with support for multiple interfaces and communication protocols. These tools allow for quick setup and compatibility with existing systems. The streamlined integration process reduces downtime, improves efficiency, and helps keep project costs under control.

Versatility Across Industries

The Xsens Sirius Series is adaptable for land, air, and underwater applications thanks to its precise inertial sensors and rugged build. Its wide temperature range and resistance to humidity, salt water, shock, vibration, and electromagnetic interference ensure reliability in varied conditions. This makes it a vital tool in various industries, including marine, agriculture, mining, and construction.

Marine Industry

The 3D orientation tracking offered by the Xsens Sirius Series delivers performance and reliability in both surface and sub-surface applications. These sensors provide precise navigation and stabilization for surface vessels, buoys, platforms, and sub-surface robotics such as ROVs (Remotely Operated Vehicles) and AUVs (Autonomous Underwater Vehicles). The MIL-standard IP68 rating ensures it withstands high humidity, salt spray, and sand. Submerged operations require a waterproof enclosure.

Agriculture

Modern precision agriculture relies heavily on autonomous machinery for tasks such as planting and harvesting. The Xsens Sirius Series offers accurate 3D orientation data, enabling autonomous tractors to navigate and operate efficiently, even in challenging terrains.3 Additionally, its compact design integrates easily into drones for crop monitoring.

Mining

Mining operations take place in environments with high metal concentrations, which can disrupt standard navigation systems.4 The Xsens Sirius Series, equipped with inertial sensor technology and magnetic resistance, overcomes this interference to maintain high accuracy. As a result, mining vehicles and equipment can operate with precision, even deep underground.

Construction

Construction sites are characterized by heavy machinery and high-vibration conditions. The Xsens Sirius Series features a vibration and shock-resistant signal pipeline with analog filtering, providing precise measurements and control for construction equipment, even amidst extreme vibrations.

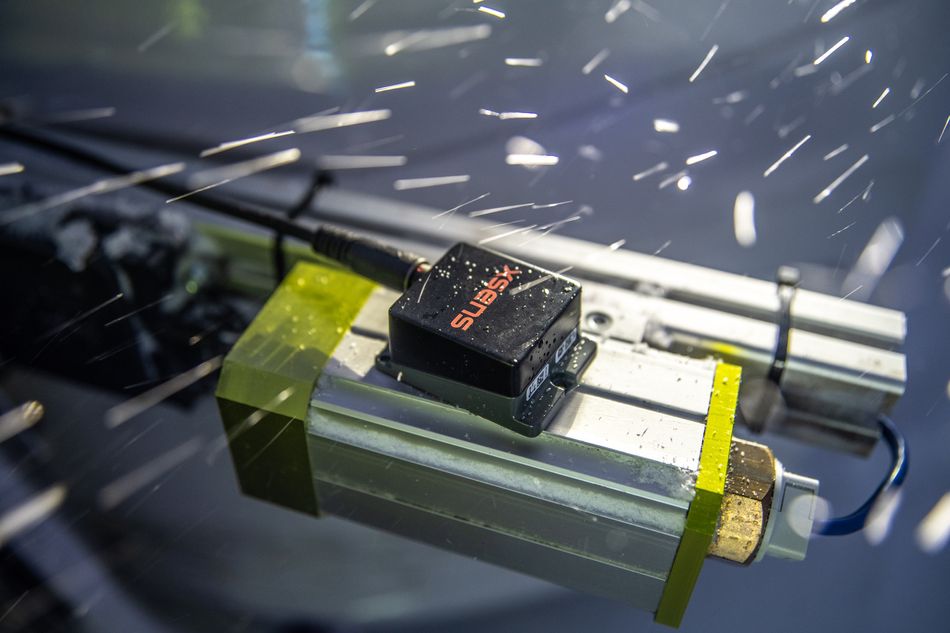

Xsens out its Xsens Sirius series to the test in one of the world’s harshest environments, Lapland, Finland, to showcase its capabilities. Partnering with the Technical Research Centre of Finland (VTT), the company subjected the Xsens Sirius series sensors to extreme Arctic conditions.

The tests were carried out using VTT’s research vehicle, Heluna, with Xsens Sirius devices mounted at multiple points to capture a broad range of motion and orientation data. The data was collected under extreme cold conditions -32 degree C with temperatures close to 0 degree C serving as a reference point for comparison. As Heluna navigated Lapland’s snowy terrain, the sensors demonstrated thermal resilience while maintaining accurate performance in the freezing conditions.

These tests highlight the Xsens Sirius line-up’s capacity to provide reliable orientation data for autonomous systems in harsh environments. To learn more about the test, check out this YouTube video.

Conclusion

The Xsens Sirius Series is designed for industries that require true autonomy in extreme conditions. With high-precision inertial sensors, a dual-processor architecture, and a rugged design, it delivers reliable performance where traditional sensors fall short. Its seamless integration ensures an easy transition into existing systems.

From marine to mining, the Xsens Sirius sensors are powering automation across industries. Their reliability has been proven in real-world tests, including in extreme Arctic conditions in Lapland, Finland.

For companies looking to stay ahead, the Xsens Sirius Series provides the precision and resilience needed to perform in demanding environments. Trusted brands including Leica Geosystems, Aeroprobe, Racelogic, and Kaarta are already leveraging Xsens Sirius technology.

If you are looking to integrate a robust 3D orientation sensor into your industrial automation projects, explore the Xsens Sirius lineup here.

Reference:

1. https://www.meticulousresearch.com/product/industrial-automation-market-5172

2. https://www.monolithicpower.com/en/learning/mpscholar/sensors/sensor-design-interfacing-and-challenges/challenges-in-sensor-deployment

3. https://www.sacaeurope.com/2025/technical/endurance-meets-precision-with-xsens-sirius/

4. https://pmc.ncbi.nlm.nih.gov/articles/PMC9345603/