Edge AI: A Paradigm Shift in Quality Control

Revolutionizing Engineering Quality Control: The Transformative Power of Edge AI

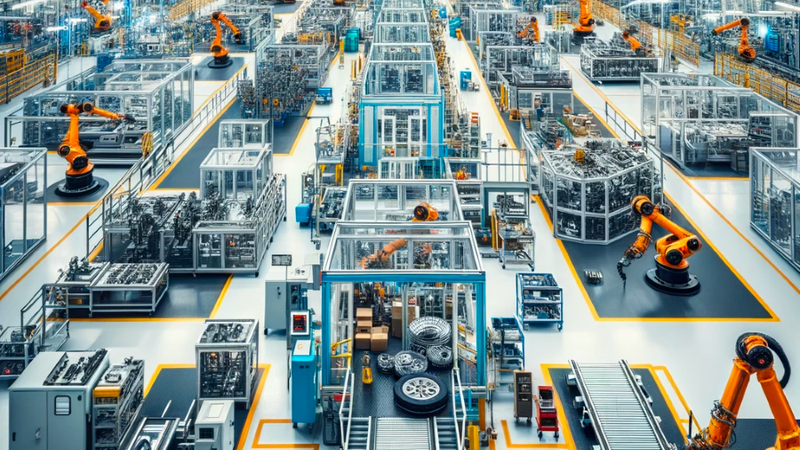

In engineering, quality control ensures the reliability, safety, and consistency of products and processes. As industries evolve, the demand for continual improvement becomes paramount, not just to stay competitive but also to guarantee the highest standards of safety and reliability. In this dynamic landscape, the introduction of Edge AI emerges as a transformative solution, poised to revolutionize quality control mechanisms.

Quality control, especially in engineering environments, is not just about maintaining standards; it's about elevating them. The competitive nature of today's industries necessitates a relentless pursuit of perfection. Traditional methods, while effective, often need more agility and real-time responsiveness than modern manufacturing and production environments require. This is where the need for continual improvement and innovation comes into play.

Edge AI, a technology that emphasizes processing data at its origin rather than relying on a centralized data center, presents a sophisticated advancement in quality control. By integrating AI capabilities directly into devices and systems on the manufacturing floor, Edge AI facilitates real-time analysis, immediate feedback, and rapid decision-making. Such capabilities are not just enhancements; they are transformational, enabling businesses to detect anomalies, predict issues, and ensure optimal quality at unprecedented speeds.

Drawing insights from various industry studies and advancements, it's evident that Edge AI's integration into quality control processes offers a promising avenue for industries to stay ahead, ensuring both competitiveness and unparalleled quality standards.

Let's delve deeper!

The Imperative of Quality Control in Engineering

Quality control has traditionally been a reactive process, heavily reliant on post-production inspections and tests. Traditional methods, while foundational, have their limitations:

Traditional Quality Control Systems: Historically, quality assurance has been downstream-focused, emphasizing production and testing. This approach, often characterized by repetitive design-prototype-test cycles, can be likened to a trial-and-error method. Such methods might only sometimes yield optimal designs, leading to increased costs, extended cycle times, and potential compromises in customer quality.

The traditional system operates on the premise that as long as a product is within specification limits, it meets customer requirements. However, the business implications of a product being "barely within specification limits" and "right on target" are vastly different.

Financial and Operational Implications: Inadequate quality control can have severe financial repercussions. Products that don't meet quality standards can lead to recalls, warranty claims, and loss of customer trust. Operationally, inadequate quality control can result in increased wastage, rework, and delays in production schedules.

Evolving Standards and Expectations: With the rapid advancements in technology and globalization, industry standards are continually evolving. Customers today are more informed and have higher expectations. They demand products that are functional but also safe, durable, and innovative. This drives the need for more robust and proactive quality control processes.

The limitations of traditional quality control methods and the changing landscape of customer expectations underscore the need for innovative solutions. As industries strive for perfection, there's a pressing demand for methods that are reactive but also proactive, predictive, and efficient.

The Advent of Edge AI in Quality Control

As traditional methods have inherent limitations, the industry is turning to innovative solutions such as Edge AI.

Edge AI refers to deploying artificial intelligence algorithms directly on the devices where data is generated rather than processing this data in a centralized cloud-based system. This proximity to the data source facilitates real-time data processing, ensuring swift responses and immediate insights.

Addressing Traditional Limitations

Traditional quality control methods, while foundational, often lag in real-time responsiveness and agility. Edge AI, with its on-device processing capabilities, addresses these gaps. By analyzing data at the source, it eliminates the latency associated with transmitting data to a central server for processing. This not only speeds up the quality control process but also enhances its accuracy and efficiency.

Benefits of Edge AI in Quality Control

Real-time Anomaly Detection: With Edge AI, anomalies in the manufacturing or production process can be detected in real-time, allowing immediate corrective actions.

Predictive Maintenance: Edge AI can predict equipment failures before they occur, ensuring uninterrupted operations and reducing downtime.

Reduced Operational Costs: By processing data locally, Edge AI reduces the need for data transmission and cloud storage, leading to potentially significant cost savings. Additionally, the efficiency gains from real-time insights and predictive maintenance further contribute to operational cost reductions.

Integrating Edge AI into quality control processes signifies a monumental shift from reactive to proactive quality assurance. As industries continue to evolve, technologies like Edge AI will play a pivotal role in ensuring that quality remains at the forefront of all operations.

Spotlight on Edge Impulse

In the rapidly evolving domain of Edge AI, Edge Impulse stands out as a pioneering platform, offering a comprehensive suite of tools and capabilities tailored for deploying machine learning models on edge devices.

Edge Impulse is a cutting-edge platform designed to simplify creating and deploying AI models on edge devices. By providing a user-friendly interface, Edge Impulse allows engineers and developers to harness the power of AI without the complexities often associated with traditional machine learning workflows. One of the standout features of Edge Impulse is its ability to streamline the deployment of machine learning models directly on edge devices.

Key Features of Edge Impulse

Data Collection: Edge Impulse Studio offers a data acquisition tool that allows users to upload datasets, facilitating the training and validation of machine learning models.

Model Training: The platform provides various tools and algorithms, including the YOLOv5 object detection model, which can be optimized for resource-constrained devices.

Deployment: After training, Edge Impulse facilitates the deployment of the model on edge devices, such as the Renesas RZ/V2L Evaluation Board, ensuring seamless integration and real-time performance.

Edge Impulse's capabilities extend beyond just quality control in manufacturing. Its versatile platform can be adapted to various applications, making it a valuable tool for industries aiming to leverage the benefits of Edge AI.

Edge Impulse in Action: A Case Study

Quality inspections are pivotal in ascertaining that products meet the required standards and specifications. A case study involving Edge Impulse offers a deep dive into how cutting-edge technology can elevate these inspections, ensuring optimal product quality.

The Challenge: Manufacturers often grapple with establishing a comprehensive inspection procedure encompassing all facets of a product's quality. Traditional methods, while effective, may only sometimes offer the agility and real-time responsiveness required in modern manufacturing environments. The challenge lies in seamlessly integrating the inspection process into the existing workflow without causing disruptions, all while maintaining consistent quality across batches.

The Edge Impulse Solution: Solomon Githu, an engineer, envisioned a solution that would seamlessly integrate into existing processes and autonomously discern product quality. He conceptualized an inspection device employing computer vision and machine learning to inspect products as they traverse an assembly line swiftly.

The objective was clear: the device should autonomously determine product quality in milliseconds.

To bring this vision to life, Githu leveraged the Edge Impulse Studio. The platform's web-based interface replaced the complexities of traditional machine learning with a user-friendly, point-and-click experience. Using an object detection algorithm, the system was trained to inspect products and discern their quality rapidly. The training involved a dataset comprising both high-quality products and those with defects.

To ensure real-time responsiveness, Githu employed the Renesas RZ/V2L Evaluation Board, specifically designed for computer vision and machine learning applications. Paired with a Google Coral camera, the system was equipped to inspect products and make real-time determinations visually.

Outcomes: The system was tested using a custom-built miniature conveyor belt, with printed images of products (in this case, submersible pump impellers) moving along it. The camera, positioned above, relayed real-time visuals to a custom web application, which then displayed the products and maintained a count of the good and defective items it detected. The results were compelling: the system showcased high accuracy, aligning with the impressive performance metrics observed during model training and testing.

Conclusion: This case study underscores the transformative potential of Edge Impulse in the realm of quality control. By harnessing the power of Edge AI, manufacturers can elevate their quality inspection processes, ensuring that products not only meet but exceed the desired quality standards.

The Road Ahead

Integrating Edge AI into quality control processes has showcased transformative results in various engineering domains. As industries continue to evolve and the demand for real-time, efficient, and accurate quality control mechanisms grows, the potential for further integration of Edge AI becomes even more pronounced.

Potential Across Engineering Domains: While the manufacturing sector has been an early adopter of Edge AI for quality control, other engineering domains, such as civil engineering, electronics, and aerospace, could benefit immensely from this technology. The ability to process data in real-time at the source can lead to enhanced structural integrity checks, real-time monitoring of electronic components, and swift anomaly detection in aerospace systems.

Scalability and Adaptability of Edge Impulse: Platforms like Edge Impulse are designed with scalability and adaptability in mind. Whether adapting to different data types, integrating with various edge devices, or scaling to handle vast amounts of data, Edge Impulse ensures that diverse quality control requirements across industries are met precisely. The platform's capabilities, such as data collection, model training, and deployment, can be tailored to suit specific industry needs, making it a versatile tool for quality control.

Meeting Diverse Quality Control Requirements: As industries diversify and products become more complex, the quality control requirements also evolve. Edge AI platforms, with their adaptability, can cater to these diverse needs, ensuring that quality control is not just about meeting standards but setting new benchmarks.

Conclusion

Integrating Edge AI into quality control processes signifies a significant stride in the engineering domain. Platforms like Edge Impulse have showcased the capability to enhance these processes, offering real-time data processing and decision-making at the source. Such advancements are not just about improving efficiency but also about ensuring consistent and high-quality outputs.

Edge Impulse, in particular, has demonstrated its prowess in facilitating the deployment of machine learning models on edge devices. It is a valuable tool for industries aiming to improve quality control mechanisms. Its capabilities, ranging from data collection to model training and deployment, are tailored to meet the specific needs of various industries, ensuring adaptability and scalability.

For engineering firms, the message is clear: the future of quality control lies in harnessing the power of Edge AI. By exploring and adopting solutions like Edge Impulse, firms can position themselves at the forefront of technological advancements, ensuring they meet the evolving standards of quality and efficiency in the industry.