A flexible, foldable, highly-integrated "smart fabric" could herald the future of the cuddlier Internet of Things

Featuring "fiber devices" including a large-format display, temperature and ultraviolet sensors, a touch-sensitive input matrix, and even a heart-rate monitor, this foldable fabric is being positioned as a breakthrough for smart homes and the IoT.

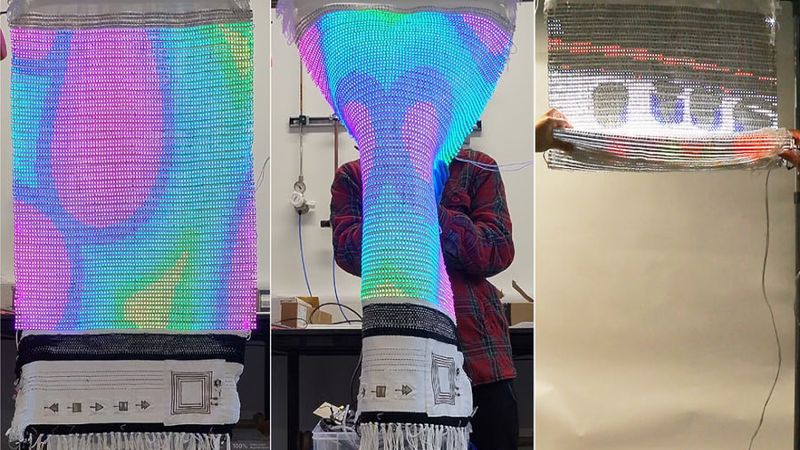

A prototype smart display, fully reproducible using industry-standard looms, is shown here being folded and rolled while retaining its performance.

This article was discussed in our Next Byte podcast.

The full article will continue below.

The idea of the fully-integrated smart home, where the very surfaces themselves boast sensing, display, and control capabilities, is an alluring one which to date has not been realized by available technologies — but a woven smart display, capable of repeated bending folding and with integrated energy storage functionality, could hold the key to changing that.

Developed by a multi-organizational team led by the University of Cambridge, the novel display system’s prototype is a 46" gadget boasting full-color display capabilities alongside wireless power transmission and energy storage, touch sensing, environmental monitoring, biosensing, and photodetection — while remaining fully flexible.

Interwoven technology

The core concept of combining fabric-weaving manufacturing approaches with integrated technology isn’t new, but has thus far struggled to scale beyond small-form-factor devices primarily targeting the wearable sector. This unnamed prototype, by contrast, targets scalability as a primary consideration: Its active display offers a 34" diagonal, with its creators claiming devices of “unlimited size” could be created using existing manual or machine looms.

Featuring a conductive silver-coated polyamide thread developed in-house as a connecting material, the heart of the smart fabric is the full-color LED display panel. Dubbed a Fiber LED (F-LED) display, the output device features a matrix of 84×76 RGB LEDs — while a second prototype boosted the resolution to 120×65, the highest resolution yet achieved in fiber LED displays.

The display is only part of the prototype, however: Designed as a true “smart fabric,” the system also includes a range of additional “fiber devices” designed to act as inputs: A square spiral fiber antenna, which can receive 13.56MHz signals as a mode switch and for power harvesting or communication with external devices; a fiber photodetector for environmental ultraviolet monitoring; a number of fiber touch sensors woven into the weft and warp of the fabric for simultaneous and multi-touch sensing equivalent to a traditional touchpad; a fiber temperature sensor; and a fiber biosensor, capable of monitoring and amplifying the user’s heartbeat for monitoring and display.

The final key feature of the overall fabric system's technology bundle: Fiber supercapacitors, made from gel-electrolyte sandwiched between carbon fiber bundles, capable of storing energy within the fabric itself for later use.

True flexibility

Despite all these functions, the smart fabric prototype remains flexible, capable of being rolled, folded, and gently stretched without damage. In extensive experimentation, all “F-devices” built into the system were subjected to standardized bending tests over 1,000 cycles and a year-long operational lifespan without any notable degradation — bar the temperature sensor, which was noted to drift over time owing to moisture ingress.

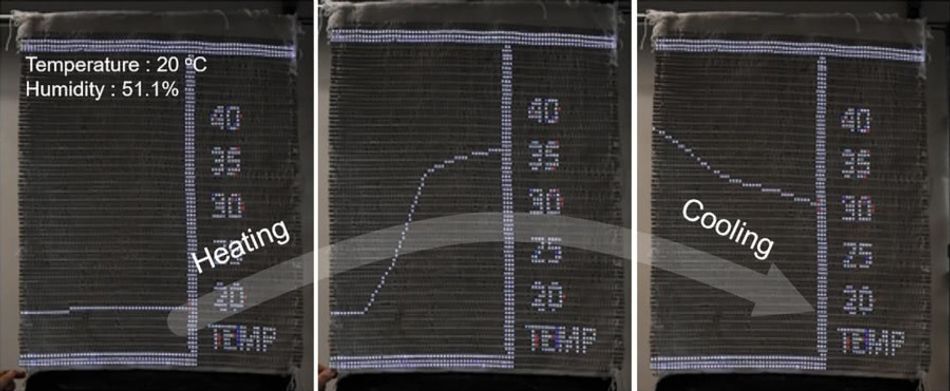

To prove the concept still further, the team tested the prototype for a range of tasks — aiming for at least one useful implementation of every F-device present. Example applications included installation of the smart fabric as a UV monitor on a window, capable of triggering the movement of blinds or activation of heating or ventilation systems via touch control; display of received signal strength from the fiber antenna; live temperature graphing; heart-rate monitoring; and automatic switching between “display mode” and “monitoring mode” depending on its distance to a radio-transmitting device.

“Our approach is built on the convergence of micro and nanotechnology, advanced displays, sensors, energy and technical textile manufacturing,” says Professor Jong min Kim, project co-lead, in a write-up of the work published here on Wevolver. “This is a step towards the full exploitation of sustainable, convenient e-fibers and e-textiles in daily applications. And it’s only the beginning.”

“By integrating fiber-based electronics, photonic, sensing and energy functionalities, we can achieve a whole new class of smart devices and systems,” adds fellow co-lead Dr Luigi Occhipinti. “By unleashing the full potential of textile manufacturing, we could soon see smart and energy-autonomous Internet of Things devices that are seamlessly integrated into everyday objects and many other sector applications.”

The team’s work has been published in the journal Nature Communications under open-access terms; the codes used in the project are available via the University of Cambridge’s Apollo system upon application.

Reference

Hyung Woo Choi, Dong-Wook Shin, Jiajie Yang, Sanghyo Lee, Cátia Figueiredo, Stefano Sinopoli, Kay Ullrich, Petar Jovančić, Alessio Marrani, Roberto Momentè, João Gomes, Rita Branquinho, Umberto Emanuele, Hanleem Lee, Sang Yun Bang, Sung-Min Jung, Soo Deok Han, Shijie Zhan, William Harden-Chaters, Yo-Han Suh, Xiang-Bing Fan, Tae Hoon Lee, Mohamed Chowdhury, Youngjin Choi, Salvatore Nicotera, Andrea Torchia, Francesc Mañosa Moncunill, Virginia Garcia Candel, Nelson Durães, Kiseok Chang, Sunghee Cho, Chul-Hong Kim, Marcel Lucassen, Ahmed Nejim, David Jiménez, Martijn Springer, Young-Woo Lee, SeungNam Cha, Jung Inn Sohn, Rui Igreja, Kyungmin Song, Pedro Barquinha, Rodrigo Martins, Gehan A. J. Amaratunga, Luigi G. Occhipinti, Manish Chhowalla, and Jong Min Kim: Smart textile lighting/display system with multifunctional fibre devices for large scale smart home and IoT applications, Nature Communications 13. DOI 10.1038/s41467-022-28459-6.