Join the 3D Printing FGF Engineering Challenge and explore the possibilities of 3D Printing with granulates.

Tagged with

additive manufacturing

ORGANIZATIONS. SHAPING THE INDUSTRY.

polySpectra

Additive Manufacturing

We help innovative engineers 3D print end-use components they can trust usi...

12 Posts

FACTUREE – The Online Manufacturer

Manufacturing | Procurement

The digital all-in-one solution for effortless procurement of custom parts

12 Posts

View more

Latest Posts

Reflecting on the Evolution of Plastics at Kunststoffenbeurs 2023: A Leap Towards Sustainable Innovation

Wevolver attended the recent plastics innovation event. We bring you the highlights.

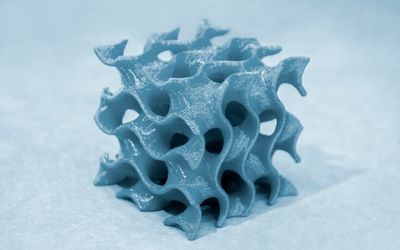

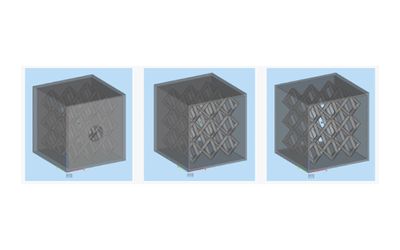

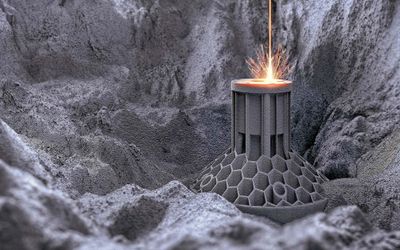

A powerful and versatile tool for engineers and 3D printing projects. Not only do lattice structures help make parts lighter and stronger, but they can also help reduce part volume, leading to fewer surface defects and excessive stress buildup. Learn how to use lattice structures in your 3D-printed parts without making a mesh of things with our design tip!

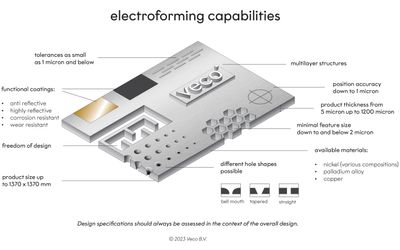

Electroforming is an Additive Manufacturing process specialized for the production of high-precision metal parts. Nickel, due to its expansive range of mechanical properties, aesthetic appeal, and resistance to corrosion, has become the most widely used material for this process. It not only enables the reproduction of extremely fine details but also permits the deposition of materials with high hardness. Electroforming technology allows depositing metal alloys to tailor specific material properties like mechanical or thermal characteristics.