Robotic Welding System to Save the Day For Welding

With the number of skilled welders decreasing and the job being rather dangerous, implementing a robotic welding system is the next step for the industry. Here's an example of such a system.

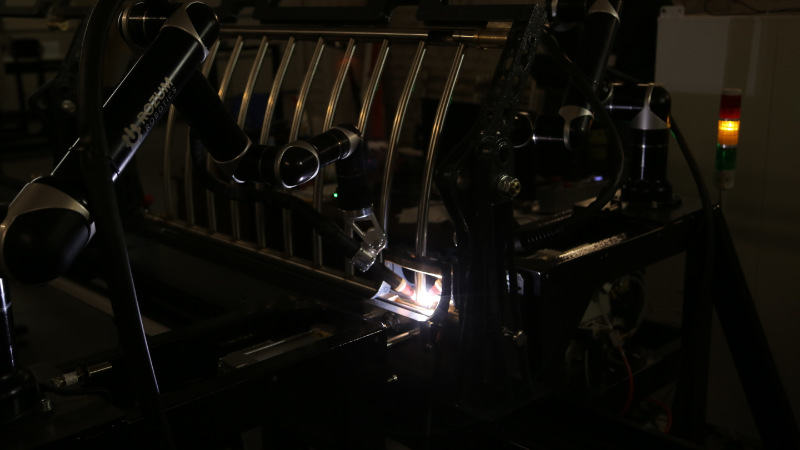

Robotic Welding System by Rozum Robotics

Welding has never been an easy job to perform. It’s repetitive, exhausting, and pretty much dangerous for the people involved. With all the ins and outs, no wonder there is a shortage of qualified welders–the one that’s only about to increase due to the expected wave of retirements and lack of younger talent.

To address the skills gap, Rozum Robotics developed an automated welding system for Tungsten Inert Gas (TIG) welding with argon gas. The scope of application was the welding of towel rail warmers from stainless steel.

The robotic system consists of two manipulators PULSE 75.

PULSE is a 6-axis robotic arm suitable for applications that need high positioning precision and steady performance. They can be used for various repetitive tasks and are pretty lightweight making it easy to integrate them even into a compact work environment. The characteristics of PULSE 75 are as follows:

Payload | 6 kg |

Reach | 750 mm |

Degrees of Freedom | 6 |

Position Repeatability | +/- 0.1 mm |

Ambient Temperature | 0...35 °С |

Weight | 12.6 kg |

Non-Stop Lifetime Cycle | 20 000+ hours |

TCP Velocity (max) | 2 m/s |

End-Effector Mounting Flange | ISO 9409-1-50-4-M6 |

Footprint | 120 mm |

Platform | Web interface. Any device |

Programming | Hand-guiding. REST API. UI |

Here’s a short brief on how the robotic welding system works:

An operator places the soon-to-be-welded towel rail warmer into the fixture. After the workpiece is fixed and a short calibration is performed, the electrode reaches the required position. Then the welding head walks along the preset pathway resulting in neatly welded seams.

The robotic welding system is completely safe for humans. The operators aren’t exposed to possible hard typically associated with the welding job. If a person accidentally moves too close to the robotic welders, they’ll shut down immediately.

The solution keeps humans out of harm's way and allows enterprises to improve both productivity and the final product appearance.