Industry 4.0 Deep Dive. Part 4: Evolving Industrial Robots

Image: KUKA

The developments that took industrial robotics from automation to collaboration.

This series investigates contemporary changes in how we work and manufacture. It’s sponsored by KUKA, developer of industrial robots and solutions for factory automation. As a sponsor, they support spreading of knowledge about the technologies that create our future factories.

The Industry 4.0 series is written as a collaborative effort from experts in the field. After we at Wevolver wrote an outline of the articles we made a call-out in our community for contributors. These contributing experts, with their wide range of backgrounds, crafted these articles and we are grateful for their dedication.

The first article introduced the topic and gave an overview of what exactly Industry 4.0 is composed of. The second article showed you how greater intelligence can revolutionize manufacturing. In the third we focused on the technologies for connecting sensors and machines throughout the factory. This fourth article reports on how industrial robotic arms evolved.

Download the entire e-book here.

About the contributors

Ottawa, Canada

Postdoctoral Fellow, Robotic Manufacturing, at the École Polytechnique de Montréal, Canada.

Professor in Advanced Additive Manufacturing, Materials for Additive Manufacturing, and Smart Structures, at the University of Ottawa.

Ph.D. Mechanical Engineering, University of Ottawa.

Per Sjöborg

Stockholm, Sweden

Founder of Aptomica.

Founder of Flexibility Envelope.

Creator and host of Robots in Depth podcast.

Karlruhe, Germany

Co-founder and CTO of Robodev

Previously leader of the Cognitive Medical Technologies group in the Institute for Anthropomatics and Robotics - Intelligent Process Control and Robotics Lab (IAR-IPR).

Ph.D. in Robotics from Karlsruhe Institute of Technology (KIT).

Adriaan Schiphorst

Amsterdam, the Netherlands

Technology journalist and editor.

MSc Advanced Matter & Energy Physics at University of Amsterdam and the California Institute of Technology.

Previously editor at Amsterdam Science Journal.

Intro

The term Industry 4.0 describes the influence of the Internet of Things on industry and the digitization of industrial processes. This concept is also described as ‘Industrial Internet of Things’ (IIoT) and Smart Manufacturing, but for simplicity we’ll use ‘Industry 4.0.’

In this fourth installment in a series of five, we’ll walk through the history of robotics in the manufacturing industry. We'll explain how electronics and mechatronics come together on the factory floor, and how through technological advancements we move towards collaborative robots.

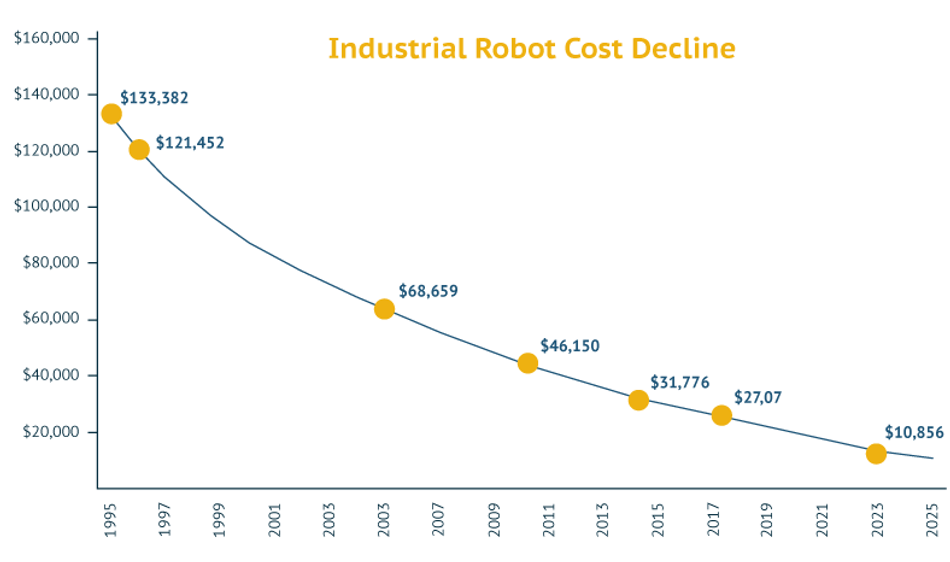

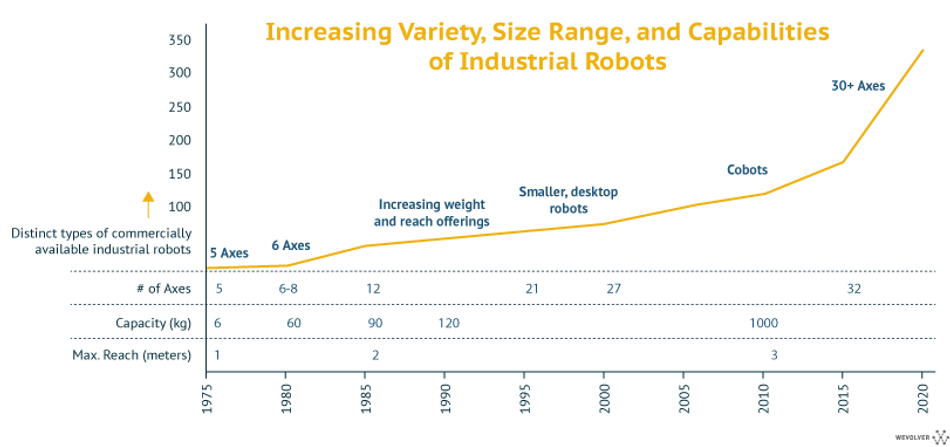

Industrial robotics for a wider audience

Robotics is entering a much wider field of application. Only ten to fifteen years ago, robotics were almost exclusively used in very large factories. But change is happening: Every day, the amount of people applying robotics in manufacturing is increasing. In 2018, global robot installations increased by 6% to 422,271 units, worth USD 16.5 billion (without software and peripherals). The operational stock of robots was computed at 2,439,543 units (+15%).1 There are vastly more engineers specialised in robotics than 20, 30 years ago. The increasing workforce creates a larger demand for different robots, for different applications, and circularly, even more people building these robots. By following Wright’s Law,2 which states that for every cumulative doubling of units produced, costs will consistently decline in percentage terms, it is evident that the cost of industrial robots will keep decreasing in the coming years. Classically, the advantages of industrial robots have been better quality and consistency, maximizing productivity and throughput, greater safety, and lower labor costs. On the other side, disadvantages are their high initial investment, the scarcity of robotic expertise, and maintenance costs.

As robotics and automation moves in new directions, so will demand. New, cheaper, and simpler robots will perform tasks now only suitable for larger industrial setups. New areas of robotics will bring humans and robots closer together, and in many new scenarios, robots and people will collaborate rather than compete. In order to successfully build a highly automated manufacturing operation, your robots have to be more individualized, better tailored, and more flexible than ever before.

To show you how robotics technology is advancing to comply with demands, we’ll first delve into the past.

The early history of robotics

The classic image of robotics in the manufacturing industry is that of the robotic arm. The patent for the mechanical arm design for Unimate, the very first industrial robot, was filed by George Devol in 1954. Joseph Engelberger, one of the founding fathers of robotics, had the chance to meet Devol, and decided to invest in his invention. In 1959, a prototype robot was used on an assembly line at a General Motors die-casting plant. It was used to transport and weld die-castings onto car bodies. The patent3 states: “The present invention relates to the automatic operation of machinery, particularly to automatically operable materials handling apparatus, and to automatic control apparatus suitable for such machinery.”

The evolution of industrial robotics was driven by human needs: The Unimate was built to alleviate human operators from dangerous and harmful tasks. Engelberger started Unimation in 1961, and soon Unimate had become the first mass produced industrial robot, paving the way for automation in the manufacturing industry, and soon beyond.

Technological advances stacked up quickly to assist robotic development. Whereas Unimate was controlled by storing systematic steps in a drum roll (magnetic memory), the 6-jointed Rancho arm became one of the first arms to be controlled by a computer when the project moved to Stanford in 1963. Growing from this prototype, the university created the Stanford arm in 1969. It used a programmable logic controller (PLC), a type of computer adapted for the control of manufacturing processes.4 Its purpose is to monitor an input, and make decisions based on a custom program to control the state of an output device. An example here would be an input from some sort of sensor or encoder sending an electrical signal to a motor, moving by means of an AC drive to a certain point at a programmed speed.

PLCs at the time were designed for specific automotive applications, and it was hard to understand for some engineers that a small box could suddenly replace 50 cabinets full of relays and wiring. The leap in functionality involved a plethora of new techniques. Familiar techniques that were used, according to the display text in Stanfords Artificial Intelligence Laboratory, are: “Computer based modeling, planning, object recognition, vision, tactile and force sensing, collision avoidance, control and manipulation.”

Industrial robotics took off quickly in the 1970s. In Europe, in 1973, KUKA Robotics introduced the FAMULUS, the first commercially available robot to have six electro-mechanically driven axes. A year later, a five axis micro-processor controlled robot was launched by ASEA (which later became ABB). Globally, more and more companies entered the field in the late '70s, especially in the US and Japan.

In 1982, FANUC entered into a joint venture with General Motors, to produce and market robots in the United States, at which time it had already secured half of the world CNC market. At the height of the robotic boom in 1984, Unimation, the company originally founded by Engelberg, was acquired by Westinghouse Electric Corporation for 107 million dollars.

Research trends driven by the needs of industry

The development of robotics in manufacturing was originally driven by the needs of the automotive industry. The predominant areas of research were kinematic calibration, motion planning and control law.

Kinematic calibration research was, and still is, aimed at improving the accuracy of a robot across its work volume.5 Based on a mathematical model, the process of calibrating is performed in four steps: After the model is made (1), sensors look for the discrepancies between math and reality (2), parameters that differ from their nominal values are identified (3) and the model is updated (4). This is often an iterative method, and fine-tuning kinematic calibration remains an open research question.

Next is the topic of motion planning. Motion planning is the calculation of sub-goals to control the completion of a robot’s spatial goal. The algorithms governing motion control for robotics have been in development since the first robot was built, but literature generally splits between two types of algorithms: implicit and explicit. Implicit algorithms specify the behaviour of the robot. In order to solve motion planning problems, the state of the robot and the state of the environment (e.g., obstacles or moving targets) are mapped to a set of inputs to control the robot. Explicit methods on the contrary provide a path or trajectory for the robot from some initial configuration to a target configuration.6

Last, the motion needs to be controlled by control laws. The motion of a robot, called a trajectory, in its essence consists of a series of desired positions, velocities and accelerations. ‘Standard’ techniques, like proportional derivative control, originated in the late 18th century, but were further developed. Here a control output based on the difference between a set point and a measured process variable is used to continuously apply corrections. Other more experimental control techniques were developed as well, like applied nonlinear control,7 a method in which nonlinear forces could be taken into control (e.g., Coriolis or centripetal forces varying with the square of the speed of the robots motion). Another more recent control method is adaptive control,8 in which adapting control laws could regulate changing variables, to account for situations where, for example, the weight of a carried object might decrease.

As robots evolved, the ability to self-adapt to product and environment became more and more important. An example of adaptation is the automation of logistics in postal services. In order to adapt to the size and shape of packages, robots had to be more intelligent so they could change their trajectories based on incoming sensor data.9

Birth of the Cobot: A trifecta of technological development

The increasing variety and capabilities of robots drive the growth of the industrial robotics market. Multiple technological developments support more widespread implementation: The adoption of wireless sensing networks (which you can read more about in article 3) provides solutions for previous extensive and expensive wiring throughout factories. As sensor and machine are further digitized, data streams start growing. Different AI techniques applied to industrial manufacturing provided robots the ability to operate in more dynamic environments, filled with more uncertain tasks. Intelligence and flexibility are provided through machine learning algorithms, using the larger availability of data, allowing robots to learn from previous selected examples and historical behaviour.

A separate revolution is taking place to allow remote control of robots. By introducing a remote human operator in the control loop through teleoperation, capabilities are extended. The success of such a system is dependent on communication. Direct control is not possible when signal delays are too high, demanding a robot to take charge when commands are absent. Wireless, remote, and smarter robots are needed and thus developed.

At the same time the first collaborative robot (cobot) is born. The patent10 from 1997 filed by James Colgate and Michael Peshkin (Northwestern University) states that a cobot is “an apparatus and method for direct physical interaction between a person and a general purpose manipulator controlled by a computer.” This technology arises from a research grant from General Motors that was set up to make robots safe enough to team up with people, to develop ‘operator-assisted’ devices. Traditional industrial robots know little to nothing about their environment, so they can hurt people close to them.

Exploiting the strengths of humans and robots

With the arrival of the new millennium, cobots start gaining traction. A typical manufacturing plant, for example an automotive assembly facility, has been transformed by the developments in robotics. The traditional body shop has become a sheet metal pressing, joint-welding automaton. Further on, the outside vehicle structure is painted by robots. However, in contrast to this, the general assembly area has not changed much. The engine, seats, tires and more are all still handled by workers. These varied, complex tasks that require a high degree of dexterity, are where cobots can make an impact.

Automation so far had mostly eliminated dangerous or repetitive tasks, and in the process it also decreased the need for human workers. The rise of the cobot addresses these sectors differently. Or, as Henry Ford II famously said: “Machines alone do not give us mass production. Mass production is achieved by both machines and men.”

Ergonomics define the development of the first passive cobots

The first cobots did not have their own power source, instead a worker provides the force needed to, for example, move a payload. When noticing that the payload is moving in a wrong direction, the cobot guides the object back to its desired trajectory.11,12

Situations where a cobot's guidance and force amplification simplify a complex task and increase the workers’ effectiveness are initially the best use cases for this new form of automation. Hence, ergonomics drive the technological development of collaborative robots, and research trends right before the turn of the millennium focus on:14

- Inertia management - motions are designed to minimize the apparent inertia felt by the operator;

- Power assistance - frictional and acceleration/deceleration forces are partly compensated;

- Force amplification - inertial, gravitational and frictional forces are compensated in a similar manner to power steering systems

Interfaces are developed to be easy to use, and safety is improved by minimizing the energy input to the cobotic systems. Modularity and tooling are developed in tandem to enable more flexible and diverse use of these still relatively more expensive devices. General Motors installs a floor-based cobot to help unload doors; this passive tool helps to control the motion of (de)installing doors, limiting the inertia felt by the operator.

Beyond the passive cobot

The beginning of the new millennium sees a boost in robotic startups. Universal Robots is founded in Denmark in 2005 to develop a light and flexible cobot. Not long after, global robotics manufacturers enter the growing market of collaborative robots and developments accelerate. The state-of-the-art cobot of today is much more than just a weight-compensator.14

Beyond increasing ergonomics, modern cobots strive for increased human-robot collaboration in industrial settings. They aim to merge robotic capabilities, such as high levels of accuracy, speed and repeatability, with the flexibility and cognitive skills of human workers. Modern cobots can check, optimize, and document the results of their own work while being connected to the cloud. Thanks to integrated sensor and communication systems, cobots safely handle sensitive products, and don’t require a protected space. Safety and intuitive control are the guiding principles in the design of cobots, which are programmed to ensure that their behaviour can be tuned or altered as easily as possible by operators. They are also increasingly aware of humans in situations where man and machine are dependent on one another.15

A modern cobot can detect contact immediately to limit its force output. It does this by having joint torque sensors in all axes. Intuitive control is enabled by the ability to program it through simulation, hand-guiding (showing a trajectory by hand) or touch commands on a regular interface.

End-of-arm tooling

We will conclude this article by examining the literal end of robotic arms. End-of-arm tooling, such as grippers, play an instrumental role in the value that a robot can bring to the user. In line with the decreasing costs of robotic arms, end-of-arm tooling options are also decreasing in price, and expanding in usability and variety. Developments include new soft robotic grippers, innovative material depositing tools, inspection tools, and assembly tools.

An example are grippers, which nowadays have to perform under demanding circumstances, and even more important, showcase a wide variability. The variability of the objects a robot needs to handle has led to production of commercially available grippers in innumerable shapes or sizes. Furthermore, because a lower capital threshold exists, there is a significant amount of small and medium-sized enterprises working on them and further pushing the boundaries of possibilities.16 Traditional mechanical grippers are becoming more versatile, modular and lightweight. More exotic are magnetic, suction, soft and vortex- (maintaining an air gap) grippers. Through innovation in contact type, manufacturers can avoid harm to sensitive, oddly shaped or volatile products.

As we've seen throughout the evolutionary history of industrial robotics, technological developments change the market, and vise versa; market developments push the technology further. The decline in costs of industrial robots is likely to continue, as will the increase in their capabilities. A specific role is designated to collaborative robots and innovations in end-of-arm tooling. Wider technological developments in Industry 4.0 that are described in other articles of this series, such as AI and wireless networking (5G), will also impact the capabilities of the robots as well as how they will be implemented in our future factories.

Robotic arms have significantly evolved, from the first Unimate to the smartest cobot, from crude welding tools to intelligent soft robotic grippers, and there is likely much more to come.

Interested in learning more? Follow this five part series on Industry 4.0: The next, final article will deep dive into digital manufacturing software and tools, simulation, and how human-machine interaction enhances human capabilities.

About the sponsor: KUKA

KUKA is a global supplier of intelligent automation solutions. They offer everything from individual components to fully automated systems. KUKA was founded in 1898 in Ausburg, Germany, and currently has roughly 14,000 employees and sales of around 3.2 billion euro. Their mission is "making life and work easier."

On their website, KUKA provides more resources and a brochure about their vision on Industry 4.0 and the solutions they offer.

References

- Executive Summary WR202019 Industrial Robots.

- Wright, T. P. Factors Affecting the Cost of Airplanes. J. Aeronaut. Sci. 3, 122–128 (1936).

doi.org/10.2514/8.155 - Devol, J. G. C. Programmed article transfer. US Patent (1961).

patents.google.com/patent/US2988237A/en - By, V. A. P. The History Of PLCs - Automation Engineer. Automation Engineer

https://www.theautomationengineer.com/education/the-history-of-plcs/ (2017). - Roth, Z. S., Mooring, B. W. & Ravani, B. An Overview of Robot Calibration. IEEE Journal on Robotics and Automation 3, 377–385 (1987).

doi.org/10.1109/jra.1987.1087124 - Lewis, F. L. & Ge, S. S. Autonomous Mobile Robots: Sensing, Control, Decision Making and Applications. (CRC Press, 2018).

doi.org/10.1201/9781315221229 - Slotine, J.-J. E., Li, W. & Others. Applied nonlinear control. vol. 199 (Prentice hall Englewood Cliffs, NJ, 1991).

- Astrom, K. J. & Wittenmark, B. Self-tuning controllers based on pole-zero placement. IEE Proceedings D - Control Theory and Applications 127, 120–130 (1980).

doi.org/10.1049/ip-d.1980.0018 - Kragic, D., Gustafson, J., Karaoguz, H., Jensfelt, P. & Krug, R. Interactive, Collaborative Robots: Challenges and Opportunities. in IJCAI 18–25 (2018).

doi.org/10.24963/ijcai.2018/3 - Colgate, J. E. & Peshkin, M. A. Cobots. US Patent (1999).

https://patents.google.com/patent/US5952796A - Edward Colgate, J., Wannasuphoprasit, W. & Peshkin, M. A. Cobots: robots for collaboration with human operators. in Proceedings of the 1996 ASME International Mechanical Engineering Congress and Exposition (1996).

- 20 Years Later: Cobots Co-opt Assembly Lines. Northwestern Engineering

https://www.mccormick.northwestern.edu/news/articles/2016/08/twenty-years-later-cobots-co-opt-assembly-lines.html (2016). - Akella, P. et al. Cobots for the automobile assembly line. in Proceedings 1999 IEEE International Conference on Robotics and Automation (Cat. No.99CH36288C) vol. 1 728–733 vol.1 (1999).

doi.org/10.1109/ROBOT.1999.770061 - Cherubini, A., Passama, R., Crosnier, A., Lasnier, A. & Fraisse, P. Collaborative manufacturing with physical human–robot interaction. Robot. Comput. Integr. Manuf. 40, 1–13 (2016).

doi.org/10.1016/j.rcim.2015.12.007 - El Zaatari, S., Marei, M., Li, W. & Usman, Z. Cobot programming for collaborative industrial tasks: An overview. Rob. Auton. Syst. 116, 162–180 (2019).

doi.org/10.1016/j.robot.2019.03.003 - Birglen L., Schlicht T., A statistical review of industrial robotic grippers, Robotics and Computer-Integrated Manufacturing, 49, 88-97 (2018).

doi.org/10.1016/j.rcim.2017.05.007.