Industry 4.0 Deep Dive. Part 5: Flexible manufacturing

Tools that enhance human capabilities and flexible manufacturing systems are necessary to deliver on the core promises of the 4th industrial revolution.

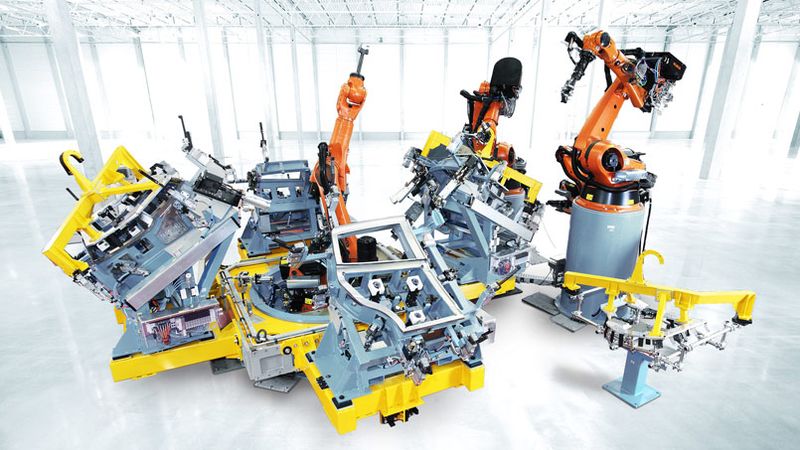

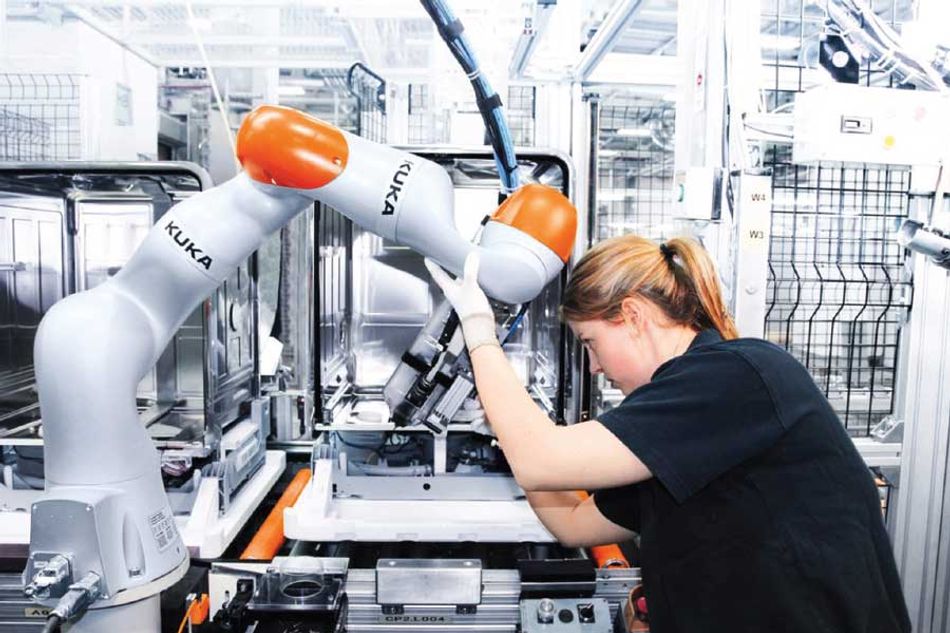

Image: KUKA

This series investigates contemporary changes in how we work and manufacture. It’s sponsored by KUKA, developer of industrial robots and solutions for factory automation. As a sponsor, they support spreading of knowledge about the technologies that create our future factories.

The Industry 4.0 series is written as a collaborative effort from experts in the field. After we at Wevolver wrote an outline of the articles we made a call-out in our community for contributors. These contributing experts, with their wide range of backgrounds, crafted these articles and we are grateful for their dedication.

The 1st article in the series introduced the topic and gave an overview of what exactly Industry 4.0 is composed of.

The 2nd article showed you how greater intelligence can revolutionize manufacturing.

The 3rd article focused on the technologies for connecting sensors and machines throughout the factory.

Then, the 4th article reported on how industrial robotic arms evolved.

Finally, this fifth and last article describes how flexible manufacturing systems controlled by advanced human machine interfaces are used to create customized products at mass production efficiency.

Update: this series has been turned into an eBook, openly access it here.

About the contributors

Ottawa, Canada

Postdoctoral Fellow, Robotic Manufacturing, at the École Polytechnique de Montréal, Canada.

Professor in Advanced Additive Manufacturing, Materials for Additive Manufacturing, and Smart Structures, at the University of Ottawa.

Ph.D. Mechanical Engineering, University of Ottawa.

Per Sjöborg

Stockholm, Sweden

Founder of Aptomica.

Founder of Flexibility Envelope.

Creator and host of Robots in Depth podcast.

Karlruhe, Germany

Co-founder and CTO of Robodev

Previously leader of the Cognitive Medical Technologies group in the Institute for Anthropomatics and Robotics - Intelligent Process Control and Robotics Lab (IAR-IPR).

Ph.D. in Robotics from Karlsruhe Institute of Technology (KIT).

Adriaan Schiphorst

Amsterdam, the Netherlands

Technology journalist and editor.

MSc Advanced Matter & Energy Physics at University of Amsterdam and the California Institute of Technology.

Previously editor at Amsterdam Science Journal.

Intro

The term Industry 4.0 describes the influence of the Internet of Things on industry and the digitization of industrial processes. This concept is also described as ‘Industrial Internet of Things’ (IIoT) and Smart Manufacturing, but for simplicity we’ll use ‘Industry 4.0’.

This is the last installment in our series on Industry 4.0. So far we’ve seen how big data, advanced analytics, and AI are changing manufacturing. We’ve looked at the role of ubiquitous, smart sensors and the networks connecting them. Then, we followed the evolution of robotics and explored collaboration between humans and robots.

In this last article in the series we’ll first discuss flexible manufacturing and how it’s achieved using the most modern digital manufacturing techniques, including hybrid manufacturing, simulation, and digital twins. We will also discuss how robots contribute to flexible automation in production lines. To achieve the highest levels of flexibility, the manufacturing industry is dependent on both automation and humans. Previously we showed how collaborative robots (cobots) allow cooperation on the work floor. Here, we will continue the story by studying how modern user interfaces and programming techniques reduce the gap between human and machine.

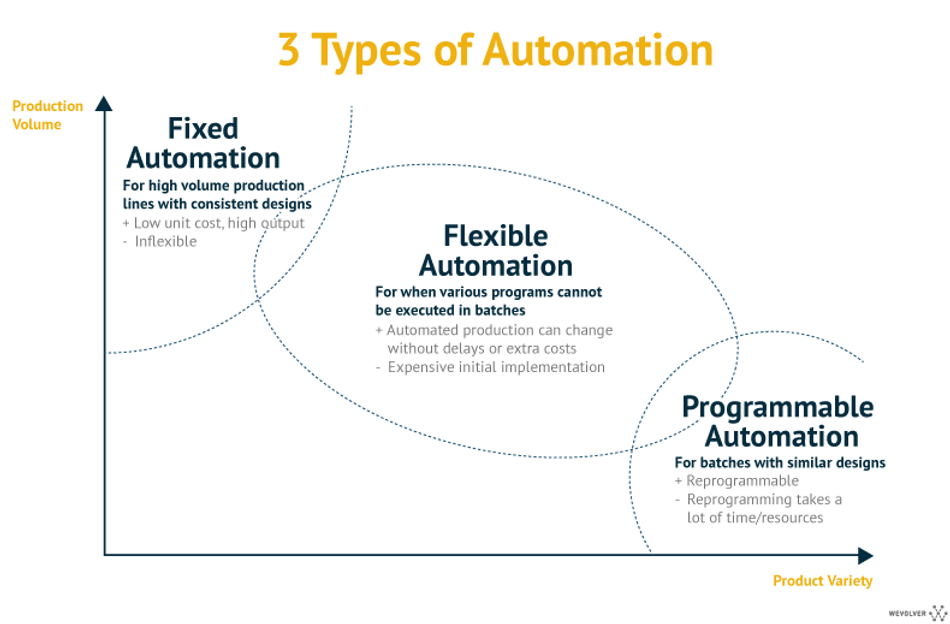

Flexible manufacturing systems

Industrie 4.0 is largely about a shift from conventional mass production models to mass customization, combining the flexibility and personalization of custom products with the low unit costs expected from mass production. Today, product customization is key to drive sales and increase customer satisfaction. Not all customers want the same products or use them the same way. In the coming years we will increasingly see personalized and more customized products, based on production models like Made-to-Order (MTO), Configure-to-Order (CTO) and Engineering-to-Order (ETO).

Furthermore, thanks to the explosion of e-commerce, manufacturers increasingly will be able to produce exactly what is ordered, moving towards the vision of lean manufacturing and stock-less inventories. This will require flexible and hyper-efficient production lines that can be reconfigured fast to produce different products. Reconfiguration, customization, and adaptation allow systems to react quickly to production changes.[1]

The most widely accepted definition of a flexible manufacturing system (FMS) is that it is an integrated, computer-controlled complex of numerically controlled machine tools, automated material and tool handling and automated measuring and testing equipment that can process any product to a predetermined schedule with a minimum of manual intervention and short change over time.[2] It integrates smart sensors, adaptive decision making models, advanced materials, smart design and machinery. Flexible manufacturing frameworks enable companies to produce a greater variety of products whilst reducing delivery lead times and inventory requirements.

Smart design processes, for instance, use techniques like computer assisted design and manufacturing to interact with product and prototypes in virtual and physical reality. The entire life cycle of the product can be monitored, simulated, and tracked. We’ll show you examples of this later on, when we talk about digital twins and simulation, but first we will look how machining has adapted to become more flexible.

Computer aided design & Computer aided manufacturing

Computer aided design (CAD) and manufacturing (CAM) have long played integral parts of the manufacturing process. CAD uses 2D or 3D software programs to create, analyze, or designs. CAM techniques use the output of those programs to automate a production process. CAM used to rely on subtractive methods like laser cutting or CNC milling, but the paradigm changed significantly with the rise of additive manufacturing (3D printing) technologies. Continuous improvements in both CAD and CAM enable software and automation to be further immersed within the product life cycle. Major developments have been made to improve the flexibility, speed, volume, and capabilities of these systems.

3D printing technology specifically continues to expand in its variety and capabilities.[3] Speed is directly connected to productivity, so development of better printing heads gains much attention, as well as developments in materials. Factors like curing time and other material properties play a big role in the printing process. Furthermore, post-processing can be very time intensive and delicate, making it a big factor to increase production speed in the product cycle.

Hybrid manufacturing

One of the more modern use cases of CAM is hybrid manufacturing. Hybrid manufacturing combines in one machine additive (3D printing) with subtractive techniques to leverage the most valuable capabilities of both methods: The geometrical complexity of additive manufacturing and the high precision of subtractive processes.

The technique is becoming a more common practice especially for metal part machining in aerospace, medical, and tool and die industries. Imagine a five axis robot, which can pick a 3D printing tool from a toolbox to deposit metal. After printing, the robot can change its tooling to a milling bit to start finishing the surface of what has been printed. Changing a single end-tool changes its function, making it a flexible manufacturing system.

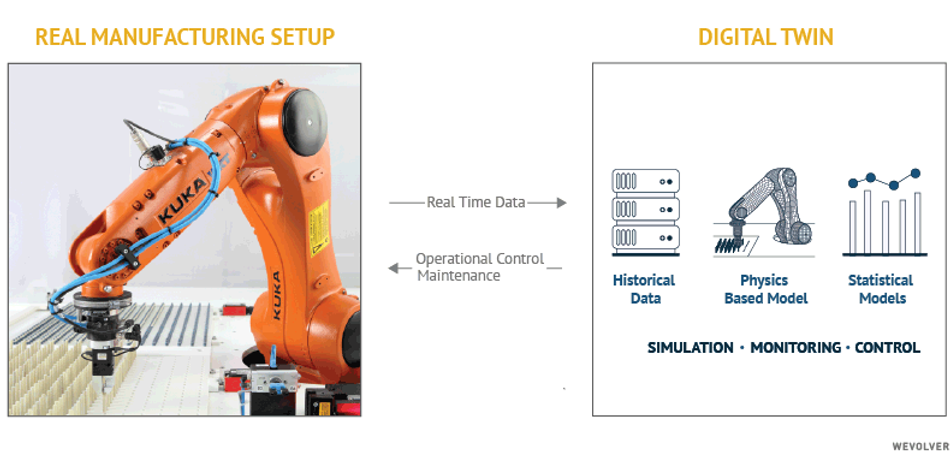

Digital twins and simulating the manufacturing process

One of the largest advantages of CAM systems is their ability to be simulated. An efficient assembly line could be mapped out and set up before the first prototype has ever been built physically. Conventional product development is a sequential process; from design to prototype, to assembly line setup, and finally actual manufacturing. A digital twin allows the development stages to be run in parallel, significantly reducing the time-frame from concept to mass production.

Digital twin (or digital shadow) stands for the simulation of a real product or process, that uses the best available physical models, sensors, and data updates to mirror the life of its physical counterpart. A digital twin is used to simulate the behaviour of a real manufacturing process, assisted by real-time monitoring and feedback. Real-world data is transmitted into the modeled system to complete simulations, validate the system, and dynamically adjust it where needed. This really separates a digital, synchronizing twin with conventional simulated systems that do not provide real-time monitoring and feedback to the field.

Digital twins have high synchronization and fidelity with the physical space, full data interaction and convergence and self-evolution. Full data interaction and convergence is the ability to connect data generated in various physical and virtual spaces with each other, not only from the manufacturing floor, but also the combination of historical and real time data. Self-evolution stands for a digital twins ability to update data in real time, so that the virtual model is continuously improving by comparison between real and virtual.

As the assembly process is mapped out in the digital twin, you can model product functionality and simulate the expected performance at the various assembly stages using the product simulation model. This can be used to develop in-line tests that ensure the product is performing as expected – to weed out early failures, mitigate yield losses and reduce scrap costs. The digital twin provides insights on the operation of the physical process without having to actually execute it.

Using digital twin based simulations, the design process in the manufacturing industry can be iteratively optimized and personalized. Digital twins can be used to quickly test new product functions, behavior, structures and manufacturability. Defects can be found easier, which speeds up verification and testing processes. Furthermore, the whole manufacturing process can be managed easier.

Before committing to the actual manufacturing process, digital twins can be used to virtually assess operators, materials, tools and the working environment. Through simulation, manufacturing strategies and planning can be made before production starts. This way, the simulated environment brings together the data from multiple aspects of the product lifecycle, stimulating better product design and the traceability of quality. It makes it easier to synergize between stages of the lifecycle, since these can be tested before implementation. Thus, using digital twins can make product development shorter, more effective, and can avoid possible errors.[4-8]

Collaborative solutions to manufacturing

Apart from simulation and digital solutions to manufacturing, humans will often still be the most flexible resource in the production environment. Increasingly humans and robots collaborate to perform even more irregular or complicated tasks.

As we mentioned in our previous article on the evolution of robotics, situations in which human robot interaction is enhanced are made possible by collaborative robots, or cobots. Cobots aim to merge robotic capabilities, such as high levels of accuracy, speed and repeatability, with the flexibility and cognitive skills of human workers by sharing each other's workspaces. An overarching aim of Industry 4.0 is higher efficiency and productivity through automation, thereby reducing costs. In this context, the role of factory workers and operators will be changing from laborious processes to knowledge intensive one.

Teaching a robotics system like an intern

So how should workers and robots work best together? One of the difficulties of using robots in industrial processes is often related to the way the human operator is supposed to interact with the robot, since it usually requires specialized knowledge. Conversely, the availability of intuitive ways to interact with robots and program them is one of the key enablers for further adoption of the robotic technologies, also by small companies. Supported by cheaper, more compact, and easier to use robotic systems, small and medium sized companies increasingly are using industrial robots too.

To take full advantage of human skills, it is important that intuitive user interfaces are properly designed, so that human operators can easily program and interact with robots. Specifically, simplified ways to interact with industrial robots in a reduced time, while minimizing user’s errors and preserving situational awareness, are needed. A lot of manufacturers are looking for a robotic system that they can teach like an intern: Show once, then perform. By giving corrective feedback and by showing what is important, the required action is defined.

Humans can teach robots on how to perform their actions, especially in cases of uncertainty where robots have not been trained on some processes. A human can instruct a robot to perform quality control on a part that the robot is unable to classify as OK or faulty. In this way, humans can help robots to accelerate their knowledge acquisition process. Such techniques can be part of active learning and Reinforcement Learning approaches, which we talked more about in part two of this series In the years to come this constructive interplay between humans and robots, will foster accuracy, flexibility and cost-efficiency in production operations.

Designing intuitive interfaces for Human-Machine Interaction

To be effective, humans and robots should be able to work together easily. Hiring experts is expensive and in most practical industrial applications, a lot of effort is devoted to programming tasks. This requires the ability to provide the robot with explicit instructions.

There are many initiatives for standard offline programming, where software tools are used to minimize a robot’s downtime. Most tools offer modules for specific processes, such as coating, welding or polishing. Although they are becoming cheaper and more accessible, most technologies are developed independently, and are not yet integrated. Typically, every manufacturer has its own specific software module with their own specific price tag.

In contrast, most newer approaches often promise more intuitive control and command, also allowing less-skilled workers to use robotic assistance. The goal here is to reduce the cognitive requirements put upon the operator, such that the robots can remain accessible to users of all skill levels. The approaches taken to design new user interfaces can mostly be classified in online programming, like traditional lead-through programming, relying on the use of a teach pendant (a control box for programming the motions of a robot) to move the robot through its required motion cycle, or walk-through programming, allowing the user to physically move the end of the robot through its desired positions. The robot is able to record and reproduce the trajectory afterwards.

Additional sensors and multi-modal interfaces for robotics

Intuitive interfaces can be designed in a human-friendly manner through speech based commands, gesture-based commands, eye tracking, facial expression and haptics; replacing the traditional keyboard to computer relation between human and machine. These developments are sometimes gathered under the term Tactile Internet, describing an environment to control the IoT in real-time using tactile and haptic sensations.

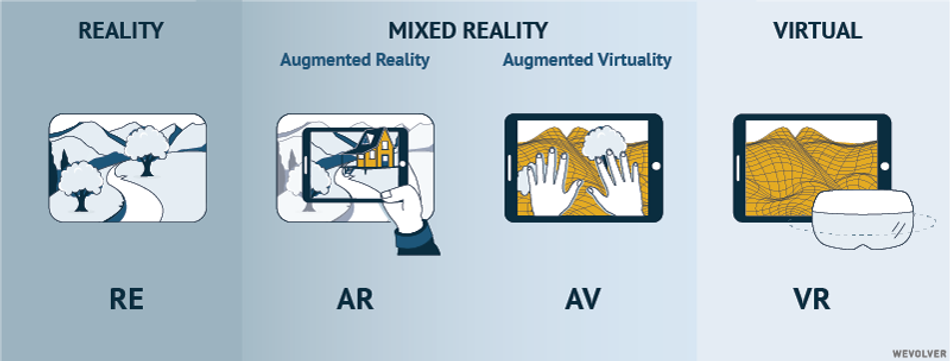

A lot of interest for human-machine interfaces (HMI) has gone towards augmented reality (AR) and virtual reality (VR). These techniques can increase productivity while also enhancing (the feeling of) safety for operators. They are further supported by simulated environments, like the ones created by digital twin technology, and complement humans' innate ability to act and interact with physical objects in a space.

The most promising use cases of AR and VR are thus also related to design, assembly, maintenance, or training. For example during assembly extra information can be displayed in the operators field of vision using AR. Another example is remote maintenance, an application of AR that is gaining momentum. It supports the technician in maintaining or repairing the machinery from a remote location, thus reducing travel for the engineer of the machine vendor and allowing high level workers to work at multiple locations.[9]

Image: KUKAModels for humans in the production line

Image: KUKAModels for humans in the production line

The aim of robot-based automation in the production line isn't to simply replace workers but rather make workplaces more productive and to enhance job environments.

A few large industries (i.e. automotive) have replaced many traditional human roles and will continue to automate where possible. Most cases where automation directly replaced human roles led to safer and more efficient environments. Direct "human to robot" replacement reflects only a percentage of global manufacturing, which currently, in general, is still dependent on humans for basic functions.

Some companies' decisions to re-integrate employees back in the production process, after previously automating their work, show other modes of operation besides 'lights-out factories' are possible. There is an opportunity for workers to enjoy job enhancement through working closely with automated processes and industrial robots. In these instances, employees have elevated their career opportunities through relearning that allows them to possess relevant skills for current and near-future industry demand.

When looking at the future, there are three possible models for humans in production lines.[10] These models don't have sharp boundaries, they form a spectrum and might co-exist in certain manufacturing environments. The choice for a model depends on the requirements and characteristics each specific case.

- The process worker concerned with monitoring the mainly automated production process. With limited responsibility this is the end of a development that would eliminate humans from the production line;

- The role model. Here, the human is a template for mechanical skills that need to be taught to machines. In this scenario the human is skilled and has a diverse array of tasks, working to better their skills outside of the production process, to be transferred later to robots to gain competitive advantages.

- The architect. The factory worker is the bridge between production using cyber physical systems, connecting customers, developers, and production lines.

That leaves many questions. How do you think humankind and machine will co-exist? What do you think the future of the manufacturing industry is? What roles will humans have? And how will you gain from these developments? In what way are the answers to these questions specific to your industry?

One thing is for sure. The roles humans can take in the factory of the future will require a different set of skills, and most certainly require new or renewed qualifications. The potential impact of this on our future of work is expected to impact not only manufacturers but also our economies and societies as a whole.

This concludes our five part series on Industry 4.0 (find the first article, the introduction, here). On their website, our sponsor KUKA provides more resources and a brochure about their vision on Industry 4.0 and the solutions they offer.

About the sponsor: KUKA

KUKA is a global supplier of intelligent automation solutions. They offer everything from individual components to fully automated systems. KUKA was founded in 1898 in Ausburg, Germany, and currently has roughly 14,000 employees and sales of around 3.2 billion euro. Their mission is "making life and work easier."

References

- Dilberoglu UM, Gharehpapagh B, Yaman U, Dolen M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manufacturing [Internet]. 2017 Jan 1;11:545–54.

http://www.sciencedirect.com/science/article/pii/S2351978917303529 - Manthou V, Vlachopoulou M. Agile Manufacturing Strategic Options. In: Gunasekaran A, editor. Agile Manufacturing: The 21st Century Competitive Strategy [Internet]. Oxford: Elsevier Science Ltd; 2001. p. 685–702.

http://www.sciencedirect.com/science/article/pii/B9780080435671500358 - Rafiee M, Farahani RD, Therriault D. Multi‐Material 3D and 4D Printing: A Survey. Adv Sci [Internet]. 2020 Apr 30;84:1902307.

https://onlinelibrary.wiley.com/doi/abs/10.1002/advs.201902307 - Schroeder GN, Steinmetz C, Pereira CE, Espindola DB. Digital Twin Data Modeling with AutomationML and a Communication Methodology for Data Exchange. IFAC-PapersOnLine [Internet]. 2016 Jan 1;49(30):12–7. A

http://www.sciencedirect.com/science/article/pii/S2405896316325538 - Tao F, Cheng J, Qi Q, Zhang M, Zhang H, Sui F. Digital twin-driven product design, manufacturing and service with big data. Int J Adv Manuf Technol [Internet]. 2018 Feb 1;94(9):3563–76.

https://doi.org/10.1007/s00170-017-0233-1 - Qi Q, Tao F. Digital Twin and Big Data Towards Smart Manufacturing and Industry 4.0: 360 Degree Comparison. IEEE Access [Internet]. 2018;6:3585–93.

http://dx.doi.org/10.1109/ACCESS.2018.2793265 - Kritzinger W, Karner M, Traar G, Henjes J, Sihn W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine [Internet]. 2018 Jan 1;51(11):1016–22.

http://www.sciencedirect.com/science/article/pii/S2405896318316021 - Rosen R, von Wichert G, Lo G, Bettenhausen KD. About The Importance of Autonomy and Digital Twins for the Future of Manufacturing. IFAC-PapersOnLine [Internet]. 2015 Jan 1;48(3):567–72.

http://www.sciencedirect.com/science/article/pii/S2405896315003808 - Villani V, Pini F, Leali F, Secchi C. Survey on human–robot collaboration in industrial settings: Safety, intuitive interfaces and applications. Mechatronics [Internet]. 2018 Nov 1;55:248–66.

http://www.sciencedirect.com/science/article/pii/S0957415818300321 - Al-Ani A. CPS and the Worker: Reorientation and Requalification? In: Jeschke S, Brecher C, Song H, Rawat DB, editors. Industrial Internet of Things: Cybermanufacturing Systems [Internet]. Cham: Springer International Publishing; 2017. p. 563–74.

https://doi.org/10.1007/978-3-319-42559-7_23