Engineering Space. Episode 1: Developing lightweight rovers for lunar surface exploration

Space startup Astrobotic mimics the moon's surface material and tests various designs of new moon rovers.

Engineering Space: EP1

Engineering Space is an in-depth documentary series that unveils the new generation of space technologies and the people and companies developing them. Engineers and entrepreneurs are democratizing access to space. Our goal is to enable you to understand the cutting-edge, be inspired, and discover practical insights to apply to your own engineering endeavors.

In the first episode of Engineering Space we meet two engineers from Pittsburgh-based Astrobotic; Principal Mechanical Engineer Kerry Quinn and Lead Software Engineer Taylor Whitaker. The space company aims to make space missions feasible and more affordable for science, exploration, and commerce. They define themselves as a lunar logistics company, intending to provide end-to-end delivery services for payloads to the Moon.

Astrobotic works out of the largest private facility in the world dedicated to lunar logistics. In this impressive 47,000-square-foot complex, The company builds and operates its lines of landers, rovers, autonomous spacecraft navigation systems, and other space technologies. Once operational, payloads will be controlled directly from the Astrobotic Mission Control Center inside their headquarters located in the heart of Pittsburgh’s North Side.

Developing lightweight moon rovers

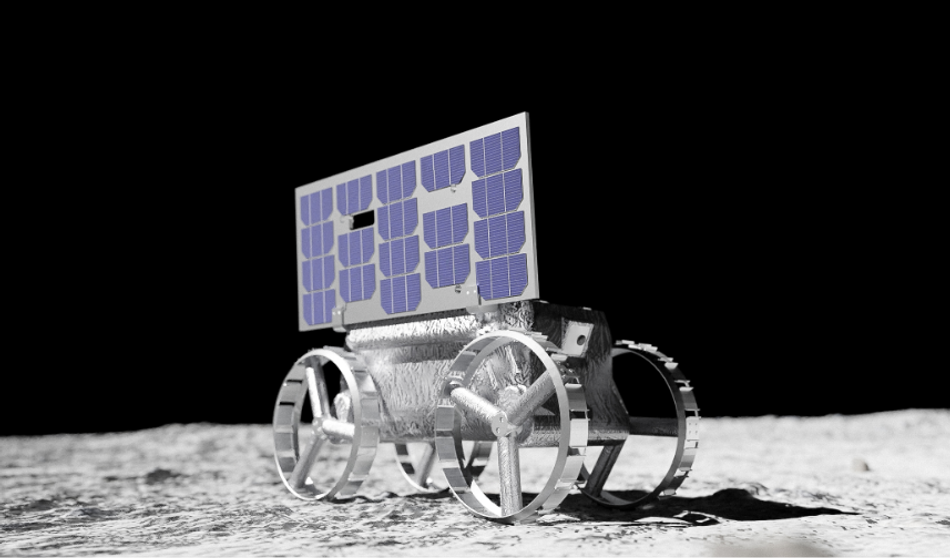

The team is developing two rovers specifically for Moon exploration. The CubeRover® is a super-light modular vehicle designed to provide affordable mobility for scientific instruments and other payloads to operate on the surface of the Moon. Because CubeRover® can be as light as just four kilograms — it can contribute to reduced flight costs, making the Moon more accessible.

The Polaris rover was designed to accommodate diverse lunar payloads with distinct mission profiles, like lunar regolith digging or water ice harvesting. Polaris can support up to 90 kg of payload mass, traverse long distances, and provide direct-to-Earth (DTE) communication. Companies, governments, universities, non-profits, and individuals can send payloads to the Moon on Polaris for $4.5M per kilogram of payload. For every kilogram of payload, Astrobotic can provide 0.5 W of continuous power and 10 kbps of bandwidth.

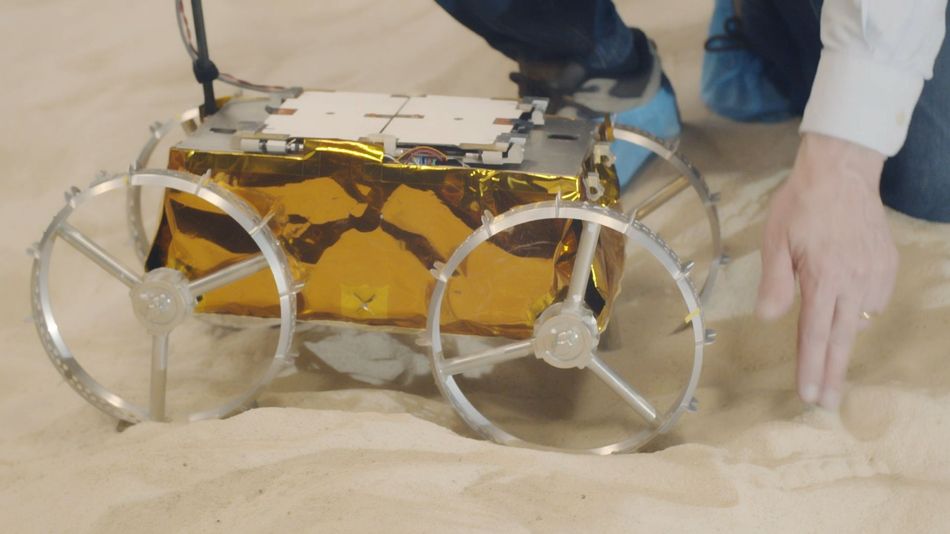

In this episode of Engineering Space, we follow along with Astrobotic engineers as they do mobility testing on the engineering model of their CubeRover®. It's the first time the team has tested the rover with its MLI (Multilayer Insulation) and electronics package. The testing will compare the engineering model with other models in development.

Mimicking the Moon's surface

Testing rovers intended for the moon requires the careful creation of an environment that resembles the moon's surface as closely as possible. The tests are conducted in their test pit of lunar regolith, a material that mimics the fine powdery material covering the moon. Almost all of the moon's surface is covered in this fine, white powdery material, with only small areas of hard bedrock on the walls of very steep moon craters.

Regolith materials are developed by NASA or other space companies. For example, the majority of the regolith used in the Astrobotic testing is made by the Glenn Research Center. The regolith, known as GRC-1[1] is made from four kinds of quartz silica.

Lunar regolith has compactibility properties[2], which means when it is agitated, it dilates or becomes lower in volume as the small particles fall between the larger particles. You can imagine this clearly by thinking of a container of flour that compacts when you tap it on a table. This is also how the iconic astronaut footprints were formed on the Moon.

This quality of the regolith means that the lightweight rovers developed by Astrobotic are expected to sink down slightly when they are on the moon, rather than moving across its surface like a small rover would on sand on Earth.

To mimic the moon without simulating in zero gravity, super lightweight versions of the rovers are developed that account for the difference in gravitational acceleration. Lunar gravitational acceleration is 1.62 m/s^2 (meters per second squared) while Earth’s gravitational acceleration is 9.807 m/s^2 (meters per second squared). The moon rover weighs about 6 kg, so the testing version weighs just 1 kg.

Design of a lunar rover wheel that sinks and turns

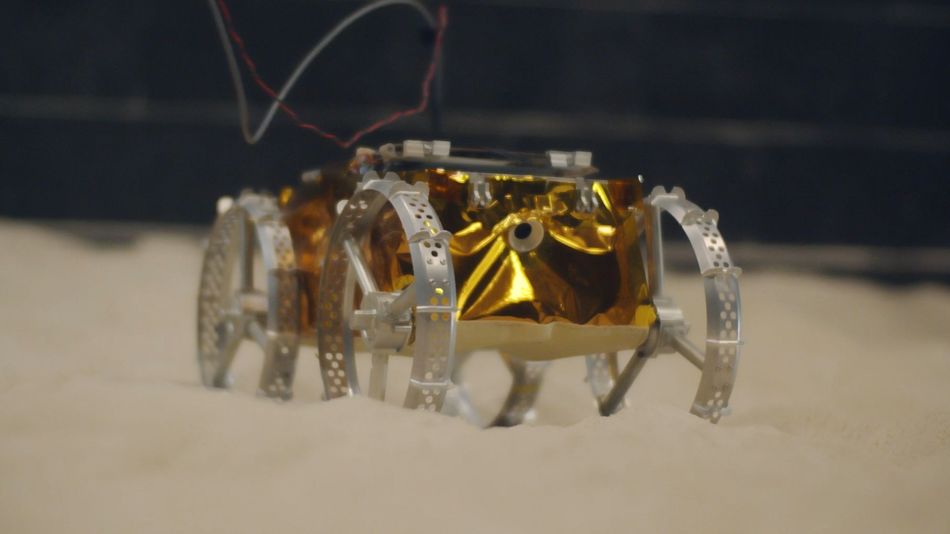

The moon surface tests enable the Astrobotic engineering team to look at each aspect of the rover, including its grip on the lunar regolith and the way it traverses different types of terrain, such as flat, ascents, and descents.

A really critical part of the rover is the design of its wheels. They must be lightweight, robust to the extreme temperatures of the moon as well as suitable for the fine, flour-like conditions of the lunar surface. The Astrobotic rover has been tested with multiple types of wheels, sizes, widths, and materials.

The current design of the wheel is fairly narrow, with regular perforations and grousers (protrusions similar to those on a tank) that allow the rover to move through the powdery surface. This design also enables the rover to complete movements such as figure-eights without the rover having a complex drive system such as articulated directional steering that would add extra weight.

The engineering model of the rover being tested is reserved for special testing as it's the closest prototype to the finished product. To protect the high-value prototype, simultaneous testing happens on other simpler versions of the rover. These tests are often specific to a single task such as hill climbing.

A mission to make the moon accessible

Astrobotic was founded in 2007 and currently has more than 130 employees. It has won several large contracts from NASA and has critical missions with the space agency planned. In addition to the rovers described above, Astrobotic has developed moon landers, a moon power grid, and vision technology.

The company's first mission is set to be the first commercial mission to land on another planetary body. The Peregrine Rover will land on the Gruithuisen Domes of the moon and deliver a range of scientific instruments, technologies, mementos, and other payloads from six different countries, dozens of science teams, and hundreds of individuals. The date of the mission will be announced shortly.

In 2024, Astrobotic will undertake the Griffin Mission One (GM1) to the Lunar South Pole. It will deliver NASA’s Volatiles Investigating Polar Exploration Rover (VIPER). Griffin will land at the South Pole and deploy VIPER to conduct the first widespread ground truth measurements of lunar water ice. Such ice may one day be used for life support and propellant that could assist future deep space explorers. Some of the instruments on PM1 will be operated as a dress rehearsal for their use on VIPER. This GM1 contract was awarded under the NASA Commercial Lunar Payload Services (CLPS) initiative.

Learn more about cutting-edge space companies and technologies

The Engineering Space documenatry series is a collaboration between engineering community platform Wevolver, and two independent Californian filmmakers and producers; Flipbird Films and Green Run Productions. This first episode is sponsored by Duro, which develops Product Lifecycle Management software for hardware engineering teams.

Having previously worked at SpaceX, I know how tough it can be to create technology that can withstand the harsh environment of space. We're proud to sponsor this Engineering Space episode and help inspire engineers everywhere!

Kellan O'Connor, COO and Co-founder of Duro

Sign up below to get updates when a new 'Engineering Space' episode gets released!

References

1. Oravec HA, Zeng X, Asnani VM. Design and characterization of GRC-1: A soil for Lunar Terramechanics testing in earth-ambient conditions [Internet]. Pergamon; 2010 [cited 2023 May 9]. Available from: https://www.sciencedirect.com/science/article/abs/pii/S0022489810000388

2. Oravec HA, Zeng X, Asnani VM. Design and characterization of GRC-1: A soil for Lunar Terramechanics testing in earth-ambient conditions [Internet]. Pergamon; 2010 [cited 2023 May 9]. Available from: https://www.sciencedirect.com/science/article/abs/pii/S0022489810000388