Tagged with

Industrie 4.0

ORGANIZATIONS. SHAPING THE INDUSTRY.

AM-Flow

Industrial Automation

We enable your adaptive manufacturing automation. Application agnostic - autonomous - always on.

View more

Latest Posts

ICS SCADA: A Comprehensive Guide to Industrial Control Systems and Supervisory Control and Data Acquisition

Dive into our comprehensive guide on the ICS SCADA system for managing and controlling industrial processes to ensure efficiency, safety, and reliability.

Dexterous Robotic Hands Part 1: Unraveling the History, Technology, and Applications of Dexterous Robotic Hands

Agile, robust, and dexterous hands are a challenging puzzle piece to the potential of robotics.

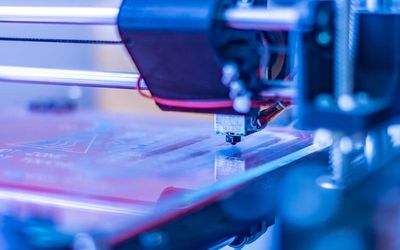

The rapid evolution of 3D printing technology has made it faster, more automated and capable of greater production volumes. Developments have reached a point where the technology offers manufacturers significant production value. It means manufacturing costs can be significantly reduced in all aspects of manufacturing, all the way from R&D to actual production.

It’s hard to believe that 3D printing has only been around since the 1980s. This technique, also called additive manufacturing, has proved so immensely useful that it’s evolving very quickly. The process was originally devised to make prototypes for one-off or small-batch parts. Materials were added progressively to build up a solid object, based on 3D digital models. It was much more cost-efficient than cutting source materials down, as no waste was apparently produced.