Open Source Leg

The Open Source Leg provides a common hardware platform for comparison of control strategies, lowers the barrier to entry for prosthesis research, and enables testing within a lab, community, and at home. In the United States, hundreds of thousands of leg amputees have a reduced quality of life due to persistent mobility limitations. To alleviate amputees’ challenges, research has focused on prosthetic leg hardware and control system design. However, progress in prosthetic leg control strategies has been stunted by lack of a uniform hardware system.

Technical Specifications

| Mass | |

| - Knee | 2160-2330 |

| - Ankle | 1740 |

| Heigh | |

| - Knee | 240 |

| - Ankle | 213 |

| Range of motion | |

| - Knee | 120 |

| - Ankle | 30 |

| Bus voltage | 36 |

| Series elasticity (knee) | 100-600 |

| Single-board computer | |

| Power | 36 |

| 950 |

Overview

In the United States, hundreds of thousands of leg amputees have a reduced quality of life due to persistent mobility limitations. To alleviate amputees’ challenges, research has focused on prosthetic leg hardware and control system design. However, progress in prosthetic leg control strategies has been stunted by lack of a uniform hardware system.

With the goal of unifying the research field of prosthetic leg controls, an open source robotic prosthetic leg (OSL) was proposed by the Neurobionics Lab at UM. This OSL is a robust and relatively inexpensive system that can be easily manufactured, assembled, and controlled. Researchers have access to downloadable hardware and software files on the project’s website, so that they can enter the research field without having to design the leg themselves. With a common platform, researchers can more easily compare control strategies and streamline the field towards highly functional robotic prosthetic legs.

The three main goals of the project are as follows:

Identify an electromechanical design for a low cost, high performance, open-source robotic knee and ankle system.

Understand how separate prosthesis control strategies can be combined to benefit amputee gait.

Evaluate the benefit of resulting controllers in amputee experiments; thereby validating the proposed open-source system as a general tool for research on prosthesis control.

Design Objectives

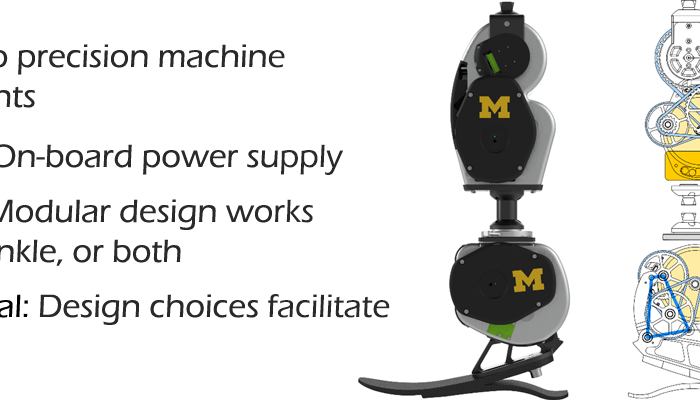

The OSL includes the prosthesis hardware, sensors, low-level control software, and an Application Peripheral Interface (API) to communicate with researchers’ preferred high-level control systems.

Transmission Design

Both joints use an electric motor coupled to a multi-stage belt drive transmission, increasing the torque provided at the output. Timing belt drives are chosen for their simplicity, low weight, low cost, and quiet operation. The transmission stages are designed to be as compact as possible while resisting tooth jump during peak torque. Newly developed PowerGrip GT3 (Stock Drive Products/Sterling Instrument, Hicksville, NY, USA) belts are chosen because they provide longer belt life, increased load-carrying capacity, and quieter operation relative to other available belts.

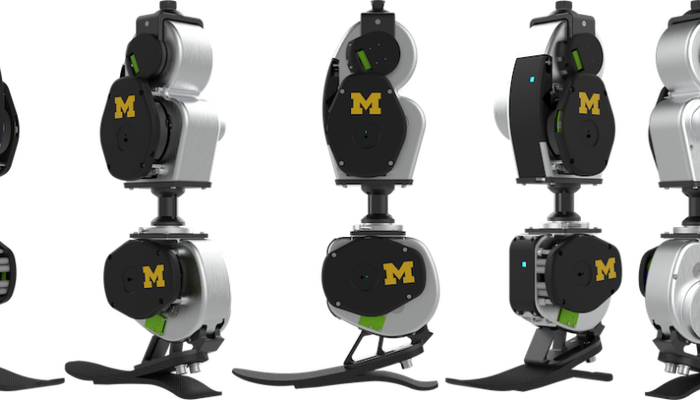

Knee Overview

The OSL has a target transmission ratio of 49:1. This transmission ratio allows the knee to achieve the torques and velocities required for locomotion while maintaining acceptable voltage and current requirements. A heuristic design exploration resulted in a three-stagebelt drive transmission consisting of a 2 mm pitch stage and two 5 mm pitch stages. Transmission components are machinedfrom7075-T6Aluminumthrough a combination of subtractive manufacturing and wire electronic discharge machining.

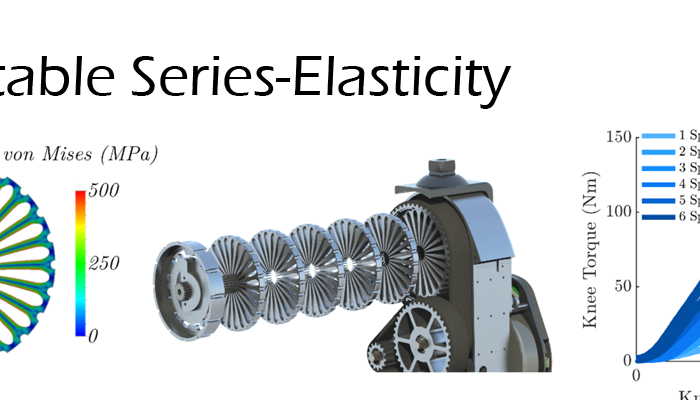

Selectable Series Elasticity

The knee design includes the ability to configure the mechanism as an SEA (series-elastic actuators), with options for a range of stiffness coefficients (including a non-SEA configuration). This ability to configure the SEA is termed selectable series elasticity. In assistive technologies and other areas of robotics, series elasticity is often implemented for improved torque control, shock tolerance, and the ability to store and return energy.

In the he knee design, series elasticity is achieved using custom torsional spring disks. Each disk is 4.3 mm thick and designed with 24 parallel, radially cantilevered beams that can deflect up to 15º. When maximally deflected, the peak von Mises stress is approximately 250 MPa (about half of the yield strength). The torsional spring disks are intended to be used with an innergear-shaped shaft. The shaft has teeth that interface with the tip of each cantilever. Relative motion between the innergear and spring disk deflects the cantilevered beams primarily through rolling contact, resulting in efficient energy storage.

Ankle Overview

The ankle design was based on the robotic knee hardware; however, a fundamental difference is that the ankle prosthesis uses a two-stage timing belt drive transmission coupled to a four-bar linkage mechanism. A four-bar linkage was chosen to reduce the overall size/heightof the ankle prosthesis. Motion of the linkage is drivenby rotation of the 2nd stage output pulley and results in rotation of the ankle joint. The angle of the linkage rocker corresponds to the angle of the ankle joint. Additionally, the rocker couples the transmission to a prosthetic foot. Two rockers are available, one for a commercially available low-profile foot (model:VLPE5250, Össur Americas), and another for a custom flat foot.

Structural Support

The transmissions of each prosthesis joint are contained within clamshell-style housings. The clamshell-style design—two halves that are fastened together—simplifies the assembly process and reduces pinch points that may lead to user or researcher injury. The housings locate the timing pulleys as well as provide structural support for the prosthesis. In addition, the housings incorporate a simple belt tensioning system that enables minor modifications to the distances between pulley shafts. Appropriate belt tensioning is necessary to ensure maximum torque capacity of the belt drive transmission. Mechanical hard stops are integrated into the housings to ensure that the OSL cannot rotate to biomechanically unsafe positions. Finally, the housings include space for batteries and electronics, creating a self-contained, portable prosthesis.

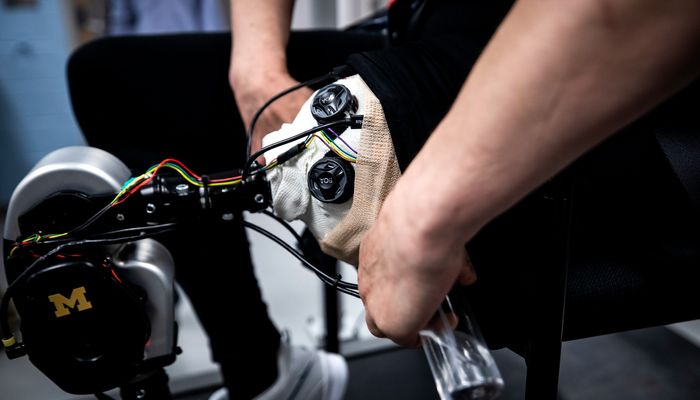

Mechatronics and Control

The OSL utilizes a brushless electric motor at each joint. Originally developed for the drone industry, high-torque, exterior rotor motors are selected based on their high specific power, and high motor constant. The motors are custom modified by Dephy Inc. (Boston, MA, USA), who also developed the brushless drive electronics. Dephy actuation technology implements Field Oriented Control commutation for the 21 pole pairs in the motors and is based on an open-source embedded platform. The Dephy brushless drive’s embedded architecture stems from the Flexible, Scalable Electronics Architecture (FlexSEA), an open-source brushless drive and motor controller developed for wearable robotic applications.

Overall prosthesis behavior is governed by a higher-level control system developed by researchers. In this application, control system commands are sent from a single-board computer (model: Raspberry Pi 3), using a custom API developed for Python. Other researchers are free to use different hardware implementations for the higher-level control system, utilizing the API. Communication between the higher-level control system and the brushless drive occurs at approximately 350-1000 Hz, depending on the communication protocol chosen by the researcher.

Electrical power is supplied onboard for each joint, enabling testing outside the laboratory. There are two identical batteries; two separate electrical power sources were chosen to permit the use of each joint independently. The power sources are 36 V lithium polymer (LiPo) batterieswith a capacity of 950 mAH (model: 25087X2, Venom Power, Rathdrum, ID, USA).

Read more about this project in this article by Dan Newman.

References

A research paper that discusses the benefits and challenges of using active prostheses, the strategy that was taken in designing the open-source leg, and the mechanical and electrical properties of the OSL.

This website contains the background information about the project, a "how to make & assemble" page, and a "how to control" page. Furthermore the page has a cost price calculation and a forum and discussion page.