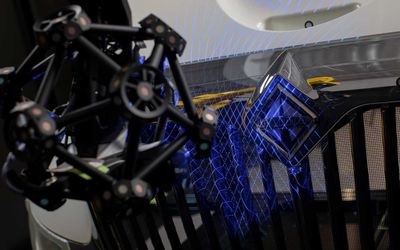

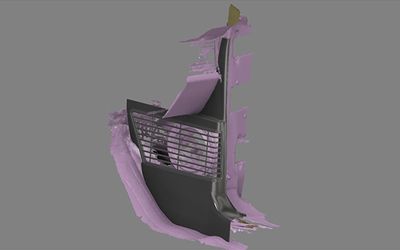

3D Measurement Systems: An Alternative Solution To Visual Inspection Systems For Inline Inspection In Smart Factories

Performing bad inspections and delivering defective parts are scenarios that manufacturing companies want to avoid imperatively. Therefore, they must detect anomalies before they become major defects and they must make corrective actions before defective parts are produced and shipped to customers.