Intelligent Code Reading for Every Industry: OMRONs VHV5-F Auto-Focus Multicode Reader

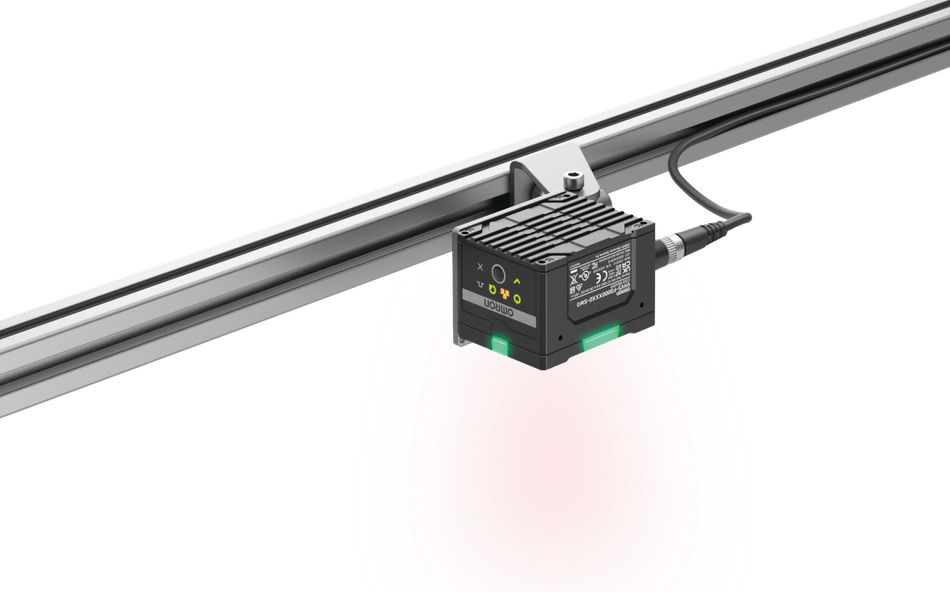

Barcodes play a key role across industries for tasks like inventory management, asset tracking, and quality control, where traceability is required. OMRONs VHV5-F enables accurate barcode reading on every surface, from curved metals to glossy packaging, even in the harshest environments.

Introduction

Industries today are increasingly focusing on speed, precision, zero-defect production, and real-time traceability. Every product, part, and process needs to be identified and logged to maintain production efficiency. One of the most practical ways to achieve this is with barcodes.

Barcode readers have evolved from simple optical scanners to become intelligent vision systems. They combine advanced hardware, sophisticated algorithms, and high-speed processing to enable scanners to consistently read all types of codes with high accuracy and high speed.

This article explores code reading, an often-overlooked yet critical aspect of modern manufacturing. It uses the OMRON VHV5-F Auto-Focus Multicode Reader as an example to illustrate how a combination of robust hardware and intelligence is transforming this critical process.

The Challenges Behind Reliable Code Reading

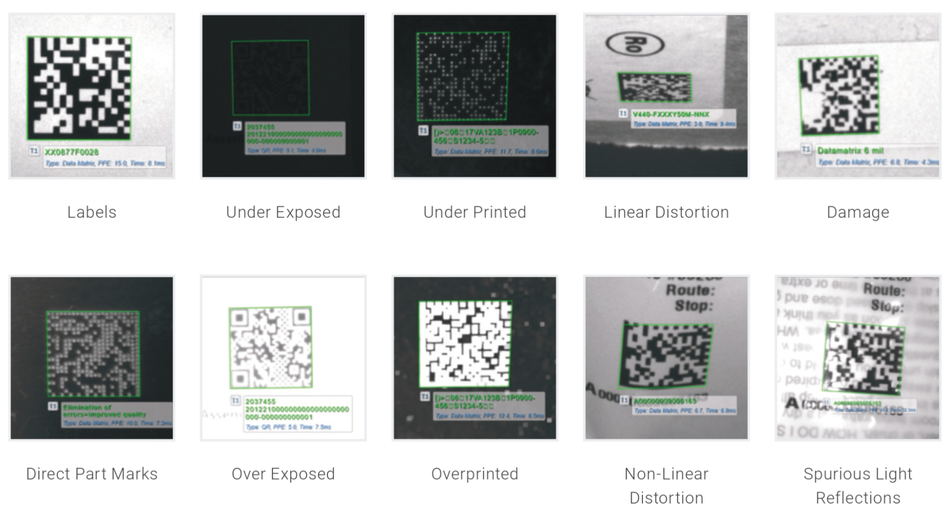

Behind every smooth-running production line, there is a constant struggle to ensure every barcode is read accurately and on time. Some challenges in code reading are:

Code diversity: Barcodes are broadly classified into just two categories: 1D and 2D. The diversity, however, comes from the different variants of these barcodes. For example, 1D barcodes include Universal Product Code (UPC), European Article Number (EAN), Code-39, Code-128, and more, whereas examples of 2D barcodes are QR code, data matrix, and more.

Variable surfaces: Codes are printed on curved, reflective, textured, flexible, and sometimes irregular surfaces. Codes on metal cases, plastic containers, or films may appear distorted, faded, or partially obscured at times, resulting in inconsistent decoding by the scanner.

Lighting inconsistencies: Shadows, glare, and overexposure are all a result of ambient factory lighting, which washes out critical details of the barcode. Without lighting control or customized optics, readers tend to struggle to keep working in such conditions.

High-speed lines: Keeping up the synchronization with speed is a critical aspect of code reading. It is not uncommon to have production lines processing thousands of parts per minute, requiring code readers to instantly decode the barcodes without causing any bottlenecks.

Manual setup dependency: Adding to all these difficulties is the dependency on manual setup. Conventional barcode scanners require extensive calibration and tuning by the trial-and-error method before they can even be deployed. This delays the initial setup and makes future reconfigurability slow.

OMRON’s VHV5-F: Bringing Intelligence to Code Reading

The next generation of industrial code reading isn’t about faster processors or sharper optics, but about the solutions that think and adapt on their own. The OMRON VHV5-F Auto Focus Multicode Reader solves the very challenges that limit the productivity of scanners in modern manufacturing by combining advanced hardware and intelligent algorithms to enable real-time decoding of all types of barcodes in all production environments.

It is a major leap forward compared to traditional barcode readers that depend heavily on manual tuning. Operators often spend hours setting the right lighting, exposure, or other settings to achieve stable results, only to repeat the process when the product type or surface changes. OMRON’s VHV5-F eliminates this trial-and-error approach with its intelligence that continuously analyzes the image quality and achieves optimal readability.

Table 1: Key technical highlights of OMRON VHV5-F

Specification | Notes |

Imaging Sensor | 2.3 MP or 5.0 MP |

Lens & Focus | Liquid-lens Auto-Focus; Narrow / Medium / Long options up to 2 meters |

Processing Speed | Multi-core parallel architecture - up to 4,000 parts/minute |

Lighting | Integrated ultra-bright LED |

Protection Rating | IP69K rugged enclosure - dust/water/high-pressure wash-down resistant |

Connectivity | PoE, TCP/IP, EtherNet/IP, PROFINET, RS-232, Digital I/O |

Software Designed for Speed and Simplicity

OMRON VHV5-F comes with the X-Mode 6.0 algorithm that lets it decode barcodes in the most challenging situations, such as under exposure, over exposure, linear distortion, non-linear distortion, damage, and poor print. It comes with a Smart Assist feature that automatically applies the appropriate filters and decodes the barcodes without any manual intervention. Engineers also have an option to train OMRON VHV5-F to work with a single type of barcode to maximise the decoding speed.

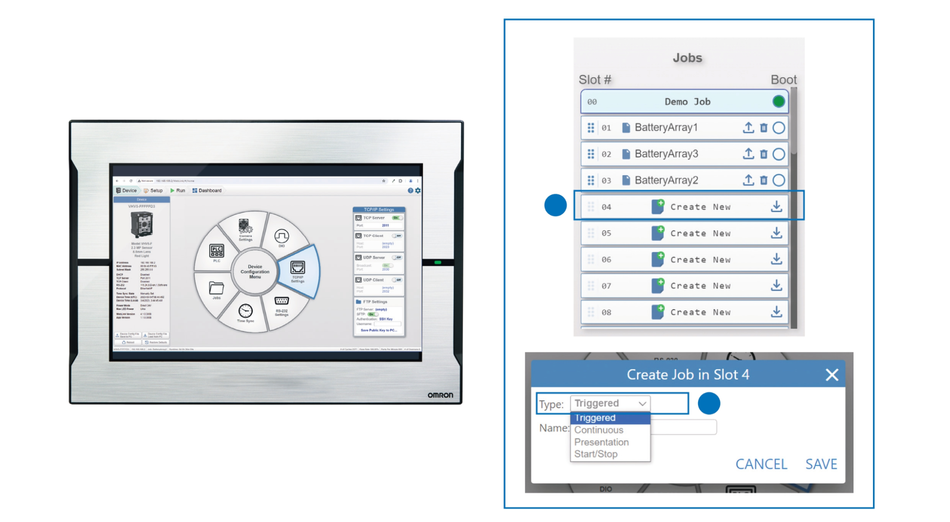

Another key highlight of OMRON VHV5-F is its remarkable ease of use. The device can be managed through OMRON’s browser-based interface, the WebLink. It eliminates the need for installing software by running directly from the device. Operators can use this interface to configure, test, and monitor the performance of the device via any other system connected to the same network by visiting the reader’s IP address.

The setup workflow is simple and requires no special training. Once deployed, the users can access the dashboard view that provides insights into the read rates, image quality, system health, and more, all at a quick glance.

Another key highlight of OMRON VHV5-F is its remarkable ease of use. The device can be managed through OMRON’s browser-based interface, the WebLink. It eliminates the need for installing software by running directly from the device. Operators can use this interface to configure, test, and monitor the performance of the device via any other system connected to the same network by visiting the reader’s IP address.

The setup workflow is simple and requires no special training. Once deployed, the users can access the dashboard view that provides insights into the read rates, image quality, system health, and more, all at a quick glance.

For system integrations, the scanner supports all commonly used industrial connectivity options such as PoE, TCP/IP, Ethernet, PROFINET, RS-232, and digital I/O. These design choices make VHV5-F the right fit for any production line.

Applications Across the Industries

The versatility of the VHV5-F makes it suitable for every industry, each presenting unique challenges in code reading. Some examples include:

Food and Beverage

In the food and beverage industry, reading barcodes is critical for package integrity, traceability, and compliance with safety standards. The VHV5-F excels in this scenario by maintaining high read rates on glossy or transparent packaging while withstanding rigorous washdown cycles.

With OMRON’s barcode scanning solution, manufacturers are able to maintain uninterrupted operation while reducing product rejections and ensuring every package is correctly identified before leaving the line.

Automotive

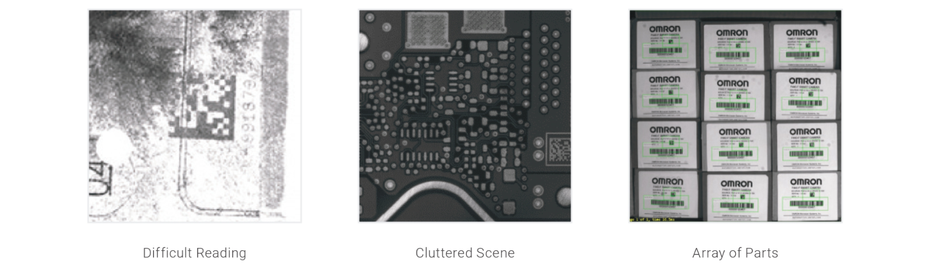

In the automotive manufacturing industry, VHV5-F can read direct part marks (DPMs) on metal parts, often placed on curved or recessed surfaces that are far from the scanner. The smart assist capabilities ensure the code is accurately decoded even when markings vary in depth and finish.

Electronics

The high-resolution sensor and autofocusing capabilities of VHV5-F enable it to decode tiny laser-etched 2D barcodes from the printed circuit boards (PCBs). It compensates for surface reflections, positioning errors, and low-contrast markings automatically in real-time.

Logistics

The large depth of field and long-distance reading capabilities enable VHV5-F to capture and process multiple barcodes in a single scene. This makes it ideal for sorting systems, conveyor belts, and mixed-package handling, where traditional scanners are slow and often struggle.

Conclusion

Barcode reading seems like a trivial process, but it is, in reality, a complex operation influenced by factors like material, lighting, line speed, and various environmental conditions. As manufacturing demands higher levels of automation, the need for intelligent, reliable, and adaptive code readers is more prominent than ever.

OMRON VHV5-F Auto-Focus Multicode Reader is a high-performance code-reading solution that combines high-resolution imaging, advanced optics, and intelligent decoding algorithms to read every code, on every surface, and in every industry.

Ready to upgrade your code-reading capabilities? Check out the OMRON VHV5-F Auto-Focus Multicode Reader on Mouser Electronics.

References

[1] OMRON Corporation. Auto-Focus Multicode Reader VHV5-F Brochure: Any Code. Any Application. Any Operator. Any Production Line [Internet]. Available from: https://www.mouser.com/pdfDocs/VHV5-Brochure-OAA.pdf

[2] OMRON Corporation. VHV5 Quick Start Guide: How to Set Up and Use the VHV5 [Internet]. Available from: https://www.mouser.com/pdfDocs/VHV5-Quick-Start-Guide-202505-r1.pdf

[3] OMRON Corporation. User Manual: Autofocus Multicode Reader VHV5-F Series [Internet]. Available from: https://www.mouser.com/pdfDocs/VHV5-Users-Manual.pdf