High Performance Connectivity in Robotics

Article #2 Robot Control Series. Robots unique set of operating conditions and requirements need intricate and delicate electronic systems to deliver high-performance networking and connectivity.

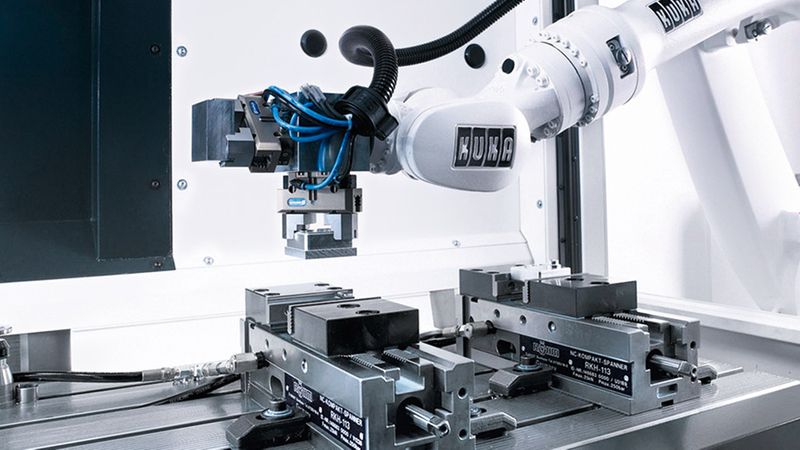

Image credit: Beckhoff/KUKA

This is the second article in a 7-part series examining solutions for robot control. The series looks into solutions for power, data, and signal, necessary to push the role and capabilities of industrial robots. This series is sponsored by Mouser Electronics, an online distributor of electronic components. Through their sponsorship, Mouser Electronics is dedicated to sharing knowledge about the possibility of a greener, more reliable, and better-connected manufacturing future.

Successful robotics connectivity only happens by design. Intricate and delicate electronic systems must work to monitor, control, and adjust robotic performance through real-time adjustments. When it's well-designed, the result is a reliable high-performance network of machine systems working to keep industry moving.

This article will discuss some of the critical design considerations that engineers should consider when designing or looking for connectivity solutions for industrial and commercial robotic applications.

Ability to Handle Harsh Environments

Industrial environments can be harsh places, especially for sensitive electronic components. Extreme temperatures, moisture, chemicals, contaminants, and high levels of vibration, and high-speed motion are a few of the environmental factors robotic equipment may be subjected to in an industrial setting.

Moisture and Contaminants

Keeping out moisture and contaminants is a key concern for industrial products. By addressing designs to fulfill Ingress Protection (IP) and National Electrical Manufacturers Association (NEMA) codes, products are delivered that prevent the ingress of water and foreign objects (e.g., dust or fibers), as well as corrosive agents and various gases and atmospheres.

An IP Rating (Ingress Protection Rating) is a rating created by the International Electrotechnical Commission used to classify the different levels of sealing effectiveness provided by an electrical enclosure against foreign bodies such as objects, water, dirt, etc.

Connectivity solutions in an industrial setting should provide IP66/67 protection when connected. IP66 enclosures protect against water projected in powerful jets (12.5 mm nozzle), while IP67 enclosures are able to protect against immersion in water up to 1m.

Extreme Temperatures

Exceptional cold wreaks havoc on parts, causing them to be brittle and stiff. This causes an increase in failure rates, as well as the potential for physical damage through cracking or other physical defects. For components such as connectors, make sure they can sustain operation in temperatures down to -25°C and up to +130°C.

Vibration and Dynamic Motion

Industrial and robotic equipment may get subjected to some of the most extreme forms of vibration. Relative movement stemming from an aggressive and highly dynamic motion profile may push connector systems to their limits. Make sure to choose products designed to specifically minimize relative movements and ensure long-lasting and reliably stable connections. Parts and systems are designed to withstand high g-forces in various axes to endure the ongoing and continuous physical jarring and shaking, rendering them tenacious and essentially indefatigable. TE Connectivity’s Dynamic Series Ruggedized Connectors are an example of connectors designed for high vibration applications.

Lasting Endurance

Industrial robotic systems need robust technological architectures, which require their components to be designed for resilience and longevity. To this end, always choose a parts manufacturer who designs with these factors in mind. By analyzing what types of environmental stresses these components must withstand, and factoring in the time duration of these stresses with equipment life cycles yield, you can develop an expectation of the high-performance requirements needed. Test criteria are generated to help ensure that any production items will survive and perform in the field to meet stringent expectations.

Polarized Connectors

Polarized connectors or mechanically-keyed connectors significantly aid in the connector mating process by helping to prevent mismating, guaranteeing positive alignment and proper connection primarily when the connector is located in hard to reach places or in instances when a blind connection might be required. Polarized connectors help eliminate unwanted connections from occurring. In an associated manner, modular connectors provide flexible and quick adaptation to the requirements of your application.

High-Cycle Count

High-cycle count connectors mean they can be engaged and disengaged often without degradation. High-cycle count connectors indicate that the connector design is durable because no electrical or mechanical defects are expected to occur as a result of repeated distinct connecting.

Conclusion

Industrial environments can place a high amount of stress on robotic equipment, especially their connectors. When choosing industrial connectors, be sure to choose products designed for endurance, protection, durability, environmental rigor, wide operating temperatures, vibration immunity, high-cycle count connectivity, and easy mating. Delivering more data, power, and signal into industrial robotic systems produces more exceptional results that will have robots and their human overlords smiling.

This article was initially published by Mouser and TE in an e-magazine. It has been substantially edited by the Wevolver team and robotics writer Dillon Garrison. It's the second article of a 7-part series exploring solutions for robot control. Future articles provide an overview of servo motor connections, discuss the role of digital twins in robot connectivity and look at trends in manufacturing automation.

Article one looked at gains made by improved connectivity in industrial settings.

Article two looked at the quality of connectors for harsh environments.

Article three provided an overview of common motor types.

Article four listed 6 Connectivity Solutions For Industrial Robotic Applications.

Article five explores cobots and connectivity.

About the sponsor: Mouser Electronics

Mouser Electronics is a worldwide leading authorized distributor of semiconductors and electronic components for over 1,100 manufacturer brands. They specialize in the rapid introduction of new products and technologies for design engineers and buyers. Their extensive product offering includes semiconductors, interconnects, passives, and electromechanical components.