The engineer's guide to Industrial IoT and Industry 4.0

An overview of the architecture of IIoT and how it is developing to drive the scalability of Industry 4.0.

Together with Arduino Pro, we are creating a series of content about the Industrial Internet of Things (IIoT), Industry 4.0 and use of embedded sensors in the value chain. This guide provides an overview of the architecture of IIoT and how it is developing to drive the scalability of Industry 4.0. Future articles will dive deeper into edge processing and machine learning and broader applications for IIoT such as smart agriculture.

This guide was written by John Soldatos, an Internet of Things and Industry 4.0 consultant and Honorary Research Fellow with the University of Glasgow , with editing and additions by Wevolver.

Introduction

In recent years, industrial enterprises are accelerating their digital transformation and preparing themselves for the fourth industrial revolution (Industry 4.0).[1] Industry 4.0 entails the digitization of physical production processes towards optimizing and controlling them using advanced technologies like BigData analytics and Artificial Intelligence (AI). This digitization of production processes enables industrial organizations to implement agile and responsive manufacturing workflows, which rely on flexible Information Technology (IT) systems rather than on conventional Operational Technology (OT). This flexibility facilitates a shift from conventional Made-to-Stock (MTS) manufacturing to novel customizable production models like Made-to-Order (MTO), Configure-to-Order (CTO), and Engineering to Order (ETO).

The implementation of Industry 4.0 compliant production systems hinges on the deployment of Cyber-Physical Systems (CPS) in the manufacturing shop floor. CPS systems enable the acquisition of digital data about physical production processes and the execution of digital-driven actuation and control processes. As such, they bridge the physical and the digital worlds and enable the digitization of complex production processes. There are different types of CPS systems ranging from sensor boards and sensor networks to smart autonomous objects like industrial robots, drones, and automated guided vehicles. In essence, CPS systems comprise one or several internet-connected devices, which are integrated with other production systems in industrial environments. This is the main reason why Industry 4.0 is also referred to as the Industrial Internet of Things (IIoT). IIoT includes the subset of IoT (Internet of Things) systems and applications that are deployed in industrial environments such as the manufacturing, energy, agriculture, and automotive sectors. According to recent market studies, the lion’s share of IoT’s market value will stem from IIoT applications rather than from consumer segments.

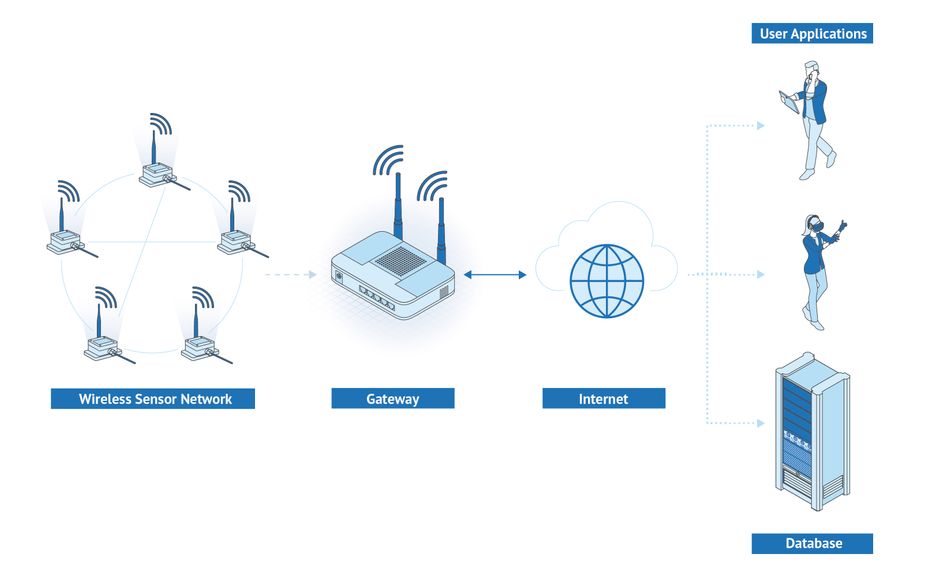

The typical structure of IIoT applications is specified in standards-based architectures for industrial systems such as the Reference Architecture of the Industrial Internet Consortium. It comprises a stack of components that includes sensors and IoT devices, IoT middleware platforms, IoT gateways, edge/cloud infrastructures, and analytics applications.

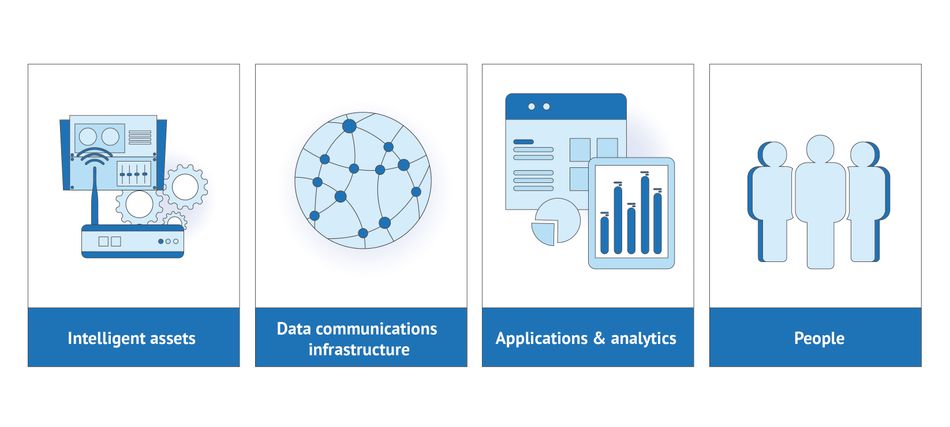

A simplified IIoT stack is illustrated in Figure 1. It consists of the following main elements:

- Intelligent assets: IIoT systems comprise internet-connected industrial assets such as industrial robots (i.e., robotics cells) and IoT-enabled machinery. Intelligent assets comprise IoT elements such as connected sensors (e.g., cameras for quality inspection), embedded sensors (e.g., vibration sensors for maintenance applications), RFID (Radio Frequency IDentification) readers, and other IoT devices.

- Data Communications: Intelligent assets comprise also network stacks, which facilitate the transmission of their data from to IT applications or other internet-connected objects. Data communications are important for conveying actuation commands from a manufacturing application or business information system (e.g., like an Enterprise Resource Planning (ERP) or Product Lifecycle Management (PLM) system) to the field. Overall, data communications are key to delivering information from the shopfloor to manufacturing applications, business information systems, and manufacturing workers as illustrated in Figure 2.

- Applications and analytics: Industrial applications collect and analyze information from intelligent assets and IoT devices. Data analytics empower optimization of manufacturing processes like quality control and asset maintenance while boosting the flexibility of automation processes. The collected data are typically integrated into a cloud infrastructure, which allows manufacturers to take advantage of the scalability, elasticity, availability, and quality of service of cloud computing. In this context, analytics applications are accessed based on popular cloud models like Software as a Service (SaaS).

- People: Industry 4.0 systems facilitate different types of manufacturing workers to perform their roles faster, with less errors and increased accuracy. To this end, they deliver insights about production operations to a variety of engineering roles on the shop floor, including for example plant managers, maintenance engineers, and quality engineers. Likewise, IIoT applications enable the business management to take data-driven, educated decisions. In several cases, Industry 4.0 boosts manufacturing automation and obviates the need for performing laborious, time-consuming, and error-prone tasks (e.g., manual quality inspection of products and parts).

The Power of Embedded Sensors in the Manufacturing Value Chain

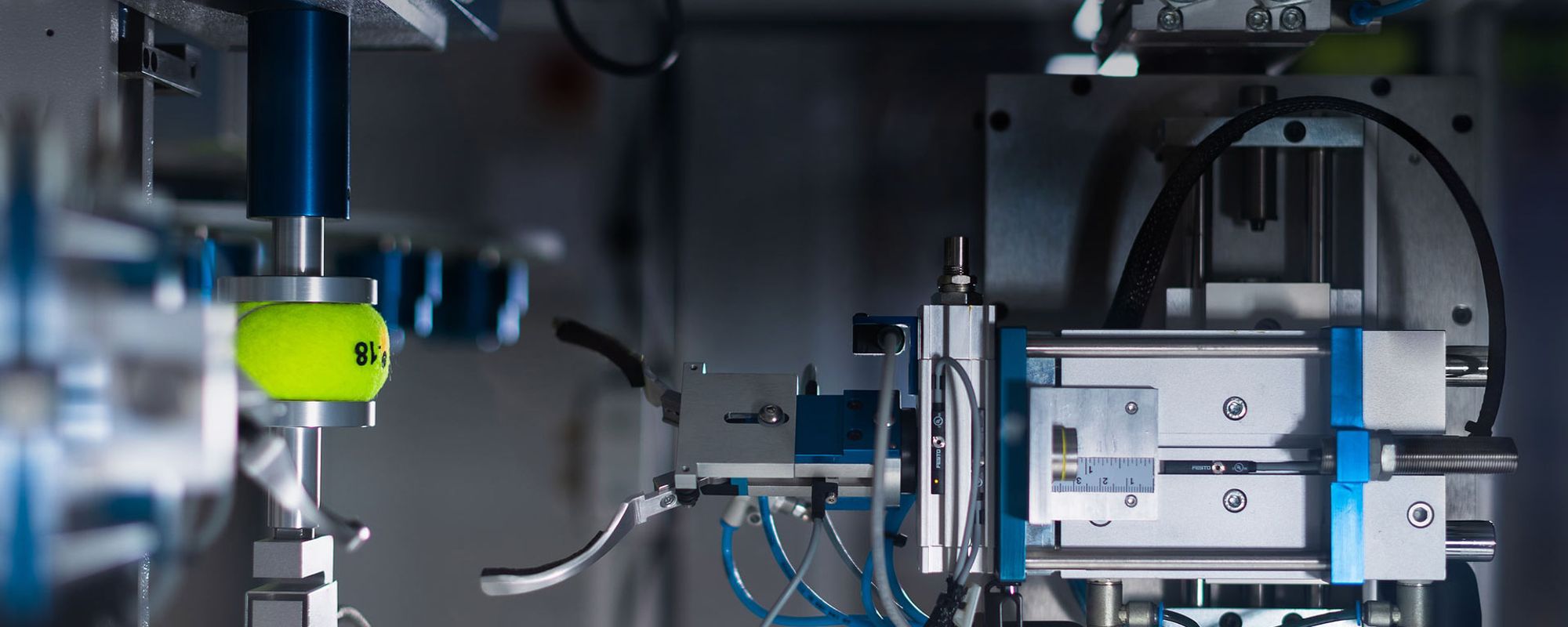

IT systems, enterprise applications (e.g., ERP and Manufacturing Execution System (MES)), and industrial networks for production automation have been around for decades. The real game-changer in Industry 4.0 is the expanded use of embedded sensors in the value chain. Embedded sensors transform manufacturing assets into cyber-physical systems and enable many optimizations that were hardly possible a few years ago. For instance, embedded sensors are deployed within machines to monitor their status and optimize their maintenance schedules in ways that eliminate unplanned downtimes and maximize their utilization. Likewise, embedded sensors enable the continuous monitoring of products and parts’ quality to detect faults as part of quality management. Furthermore, the collection and analysis of assets and processes data from embedded sensors unlocks product innovation processes and enables new business opportunities. Overall, embedded sensors and other IIoT technologies empower increased efficiencies by transforming raw digital data to factory floor insights and automation actions.

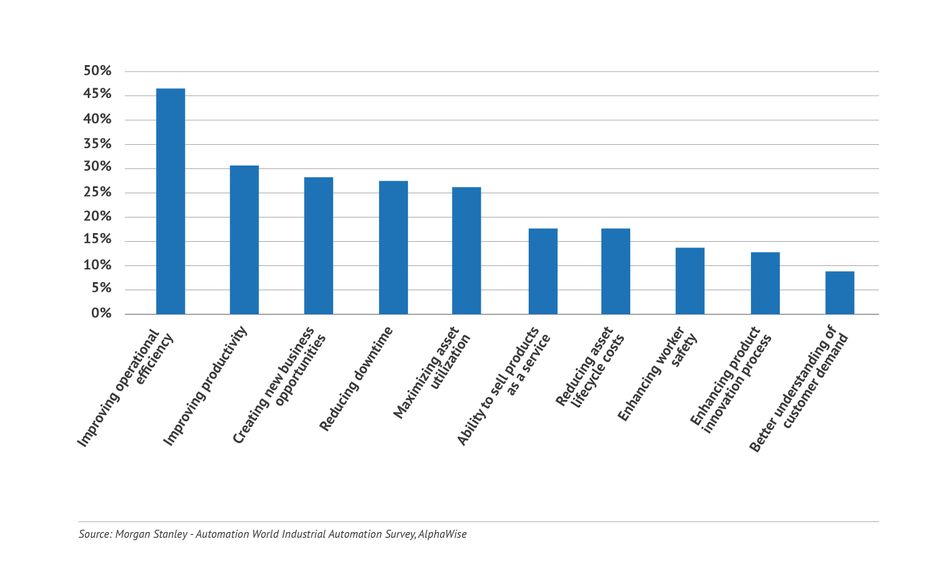

Figure 3 illustrates some of the perceived benefits of IIoT and embedded sensors deployments in production operations. These benefits are realized in the context of Industry 4.0 applications such as:

Flexible Production Lines

Thanks to the use of embedded sensors and the IIoT, production lines need no longer be tied to static configurations for mass production. Rather, production configurations can be dynamically adapted to facilitate the production of customized products and realize a shift from mass production to mass customization. For instance, by reading the RFID tag of a product a production line can dynamically decide how to handle it. Likewise, it can automatically produce and activate the proper configuration of production processes, which leads to new efficiencies in manufacturing automation.

Predictive Maintenance

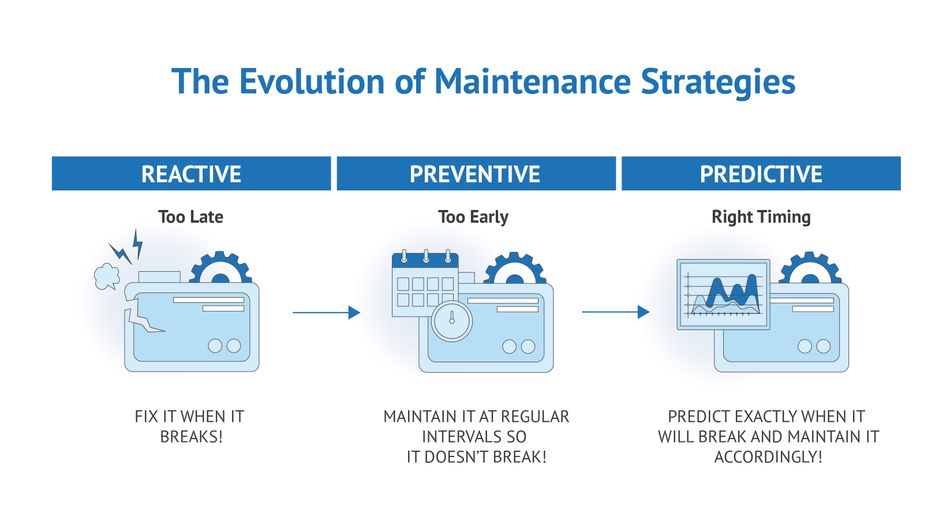

Once upon a time, manufacturing assets (e.g., machines) were repaired reactively i.e., they were fixed whenever they broke. This reactive maintenance approach led to unplanned production downtimes, which have adverse implications in production quality and cost. Over the years, many manufacturers transitioned to a preventive maintenance approach, which replaces or repairs assets proactively i.e., before their break. Preventive maintenance leverages information about the nominal End-of-Life (EoL) of the asset and helps to avoid unscheduled downtimes. Nevertheless, it still results in sub-optimal asset utilization, as it repairs or replaces assets too early (Figure 4). The promise of IIoT is to enable the predictive maintenance paradigm, which estimates the actual Remaining Useful Life (RUL) of an asset in order to optimize its service and repair schedule.[2] Predictive maintenance relies on one or more embedded sensors (e.g., vibration, acoustic, temperature, power consumption, thermal imaging, and ultrasonic sensors) to acquire data about the condition of the asset. The analysis of these data by means of Machine Learning (ML) and Artificial Intelligence (AI) techniques (e.g., deep learning) enables the credible estimation of the RUL of the asset and the planning of its maintenance at the best possible point in time. This is a foundation for optimizing Overall Equipment Efficiency (OEE) in Industry 4.0 plants. Predictive maintenance is one of the most popular Industry 4.0 applications, as it is applicable in virtually all industrial sectors like manufacturing, energy, oil and gas, and mining.

Quality Management

Embedded sensors open new horizons in product and process quality. Specifically, the analysis of sensor data enables use cases like proactive failure detection and identification. Likewise, the analysis of historical data about product conditions and production processes enables the identification of process parameters that are likely to lead to defects. IIoT’s promise for quality management is to facilitate the prediction of defects’ risks and to enable automatic actions that will prevent the materialization of these risks. In this direction, an ML/AI agent in a production line can analyze historical data to predict possible defects and initiate actions that prevent them from happening. This concept is conveniently called Predictive Quality[3] and represents the vision of quality management in the Industry 4.0 era (i.e., Quality 4.0).

Supply Chain Management

Embedded sensors are revolutionizing supply chain management. They enable supply chain stakeholders to access richer information about supply chain processes. For instance, IIoT and embedded sensors enable the traceability of products and logistics processes towards optimizing supply chain operations like demand forecasting and shipment scheduling.

Zero Defects Manufacturing

IIoT and Embedded sensors facilitate the combination of process control, predictive maintenance, and logistics optimization processes towards Zero Defects Manufacturing (ZDM). ZDM is a vision of manufacturing excellence that eliminates defects and optimizes production quality, cost, and sustainability, all at the same time. It relies on the integration of sensor-enabled reactive, predictive, and preventive strategies.[4]

Digital Twins

The deployment of embedded sensors in the manufacturing value chain is key to implementing the powerful concept of Digital Twins. The latter provide cyber representations of physical processes in the digital world, based on information from sensors, CPS systems, enterprise applications, and databases. With digital twins manufacturing enterprises can simulate complex production processes and run what-if analysis without a need for executing production scenarios in the field. As such digital twins are empowering industrial organizations to optimize processes in ways that are both cost-effective and safe for their employees.

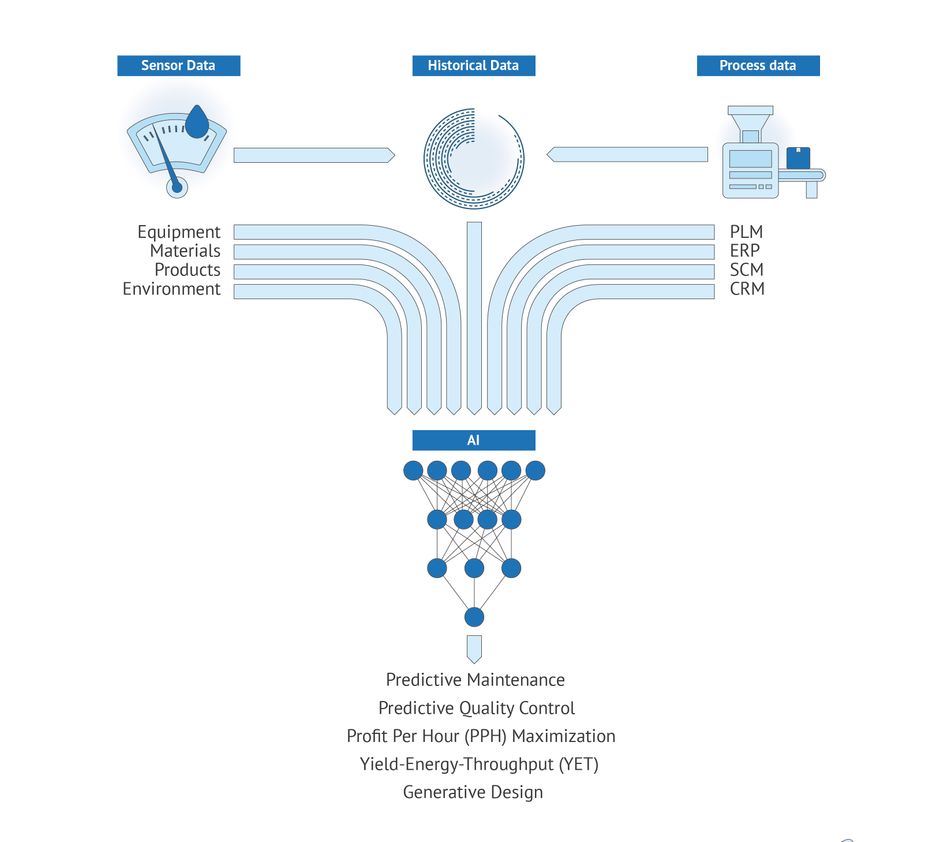

Figure 5 illustrates the main principle behind the implementation of the above-listed Industry 4.0 use cases. IIoT applications collect and integrate data from embedded sensors, production systems, and business information systems. These data are combined with large volumes of historical data about production processes that are stored in historian databases, and data lakes. The analysis of sensor, process, and historical data by means of AI algorithms (e.g., deep learning techniques) produces insights that improve production performance and optimize processes like maintenance, quality control, and product design. For instance, the execution of predictive analytics over these data boosts the implementation of predictive maintenance and predictive quality use cases. As another example, manufacturers can use AI analytics over PLM data to generate alternative product configurations based on generative design approaches. Finally, sensor, process, and historical data are used to calculate manufacturing KPIs (Key Performance Indicators) towards tracking and optimizing cost, efficiency, and environmental performance.

Data analysis options: Edge, Cloud or combination?

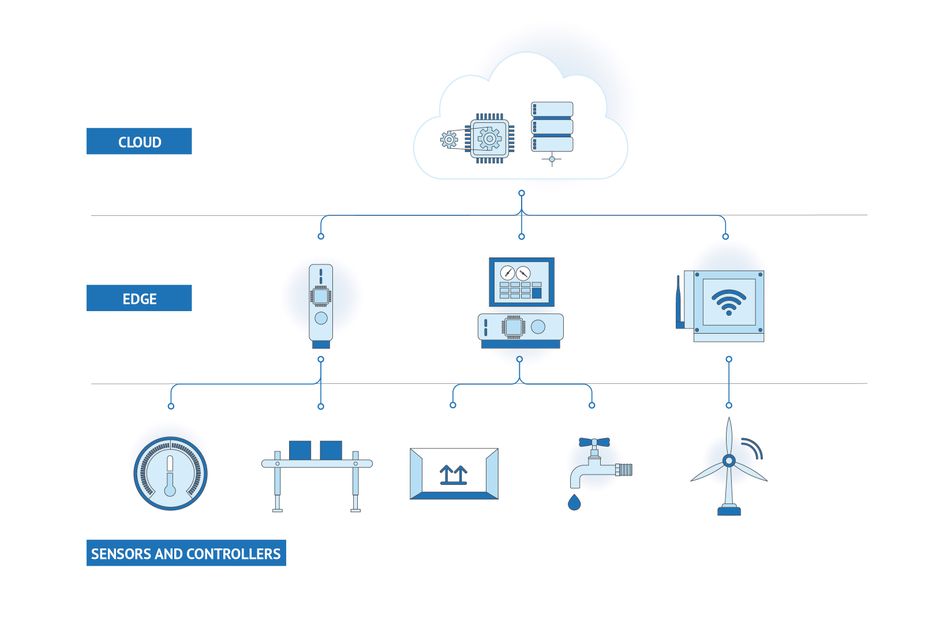

Most IIoT applications include data analytics functionalities such as sensor data analysis based on machine learning techniques. Therefore, they typically collect and process information within cloud computing infrastructures. The latter facilitate access to the required data storage and computing resources. Nevertheless, IIoT deployments in the cloud fall short when it comes to addressing low latency use cases, such as applications involving real-time actuation and control. In such cases, there is a need to execute operations close to the field (i.e., the shopfloor) that cannot tolerate delays in transferring and processing data in the cloud.

To address real-time, low-latency applications, industrial organizations are deploying IIoT applications based on the edge computing paradigm. The latter involves data collection and processing close to the field, within infrastructures like edge clusters (i.e., local cloud infrastructures), IoT gateways, and edge devices. A recent report by Gartner predicts that by 2023 over 50% of enterprise data will be processed at the edge.

Edge computing deployments are best suited for real-time control applications while helping to economize on bandwidth and storage resources. Specifically, data processing within edge devices facilitates the filtering of IoT data streams and enables enterprises to selectively transmit to the cloud “data points of interest” only. Furthermore, edge computing provides better data protection than cloud computing, as data remain within local edge devices rather than being transmitted to cloud data centers outside the manufacturing enterprise. Moreover, edge analytics functions such as AI algorithms on edge devices are much more power-efficient than cloud-based analytics.

In practice, industrial enterprises employ both cloud computing and edge computing for their IIoT use cases. Specifically, they tend to deploy real-time functions at the edge and data-savvy industrial automation functions on the cloud. There is always an interplay between cloud and edge functions towards achieving the best balance between analytics accuracy, computational efficiency, as well as optimal use of bandwidth and storage resources. Thus, IIoT applications are usually deployed in the scope of a cloud-edge environment.

Nowadays, there are many ways to implement edge computing and its interactions with cloud infrastructures. Likewise, there are also many options for employing machine learning at the edge of an industrial network, such as federated machine learning techniques or even deployment of machine learning functions in embedded devices. The latter involves a convergence of embedded programming with machine learning, which is characterized as embedded machine learning or TinyML.[6]

State-of-the-art cloud/edge computing paradigms support varying requirements of IIoT use cases in terms of latency, security, power efficiency, and the number of data points needed for training ML algorithms. Future articles in this series will shed light on the technical architecture and the deployment configurations of some of the above-listed cloud/edge paradigms.

IIoT Security

IIoT’s productivity opportunities come with a set of new security challenges. For example, there is a need to converge IT security with OT security and to ensure the trustworthiness of IoT devices. The deployment of sensors and IoT devices in the manufacturing shopfloor introduces additional vulnerabilities and asks for novel approaches to cyber-security risk assessment. Likewise, the expanded use of digital data in manufacturing use cases (e.g., the exchange of digital models for 3D printing) asks for encrypting sensitive data as a means for protecting Intellectual Property (IP). Furthermore, there are new requirements and challenges regarding the safety of industrial systems, given the need to ensure strong cybersecurity for systems like industrial robots and digital automation platforms. Finally, the use of machine learning and AI raises new security challenges such as the need for protecting industrial systems from ML-specific attacks like poisoning and evasion attacks against deep neural networks.[5] Overall, IIoT systems must account for a broader range of vulnerabilities and security risks. In this direction, there is a need for a holistic approach that secures industrial systems from the device level, up to the edge and cloud levels.

The Scaling of IIoT and the Path towards industry 4.0

Industry 4.0 has been around for over five years, yet we are still quite far from realizing the full potential of embedded sensors and the Industrial IoT. Many enterprises have started their deployment journey by setting up data collection infrastructures and deploying CPS systems and IoT devices on their shop floor. There are also several deployments of operational use cases in areas like asset management, predictive maintenance, and quality control. Nevertheless, many use cases are still in their infancy or limited to pilot deployments in pilot production lines or lab environments. Therefore, there is a need for evolving and scaling up existing deployments to enable industrial enterprises to adopt and fully leverage the fourth industrial revolution.

The scaling up of Industry 4.0 use cases hinges on addressing the following challenges technical and organizational challenges:

- Legacy compliance for brownfield deployments: Most legacy machines in industrial environments are not IoT-enabled, which is a setback to the deployment in IIoT applications. Therefore, there is a need for enhancing them with IoT capabilities based on sensors, hardware boards, and wireless sensor networks. The latter are key to deploying IIoT applications in brownfield scenarios.

- Alleviating data fragmentation in industrial environments: Data availability and integration are key prerequisites to implementing data-driven optimizations of production processes. Industrial data reside in “siloed” systems, which is a setback to their integration in effective ML/AI systems for predictive maintenance, Quality 4.0, digital twins, and other industrial use cases.

- Addressing the IoT, BigData, and AI skills gap: Nowadays enterprises face a significant talent gap in IIoT technologies. Therefore, they must upskill and reskill existing employees, while attracting engineering talent that can help them realize their digital transformation. IIoT applications that lead to manufacturing excellence are set to be built by proficient engineers that are equipped with the right tools.

- Ensuring access to pilot lines and experimentation infrastructures: This is a key to testing innovative systems and use cases. To this end, large manufacturers build pilot lines and expand their existing laboratory infrastructures. At the same time, smaller manufacturers (e.g., Small Medium Enterprises (SMEs)) must ensure their access to pilot plants and experimental facilities. In this direction, they could benefit from established Innovation Centres and Digital Innovation Hubs (DIHs).

- Easing IIoT integration end-to-end i.e., from the embedded device to the manufacturing application: There are still no easy ways to develop and deploy applications involving embedded devices, IIoT middleware, and advanced analytics applications (e.g., ML/AI). Manufacturing enterprises could greatly benefit from readily available tools that could ease application development such as zero-code development environments.

- Realizing a cultural shift towards Industry 4.0, in terms of reengineering of industrial processes and business processes. Manufacturing enterprises must embrace Industry 4.0 at the organizational and business level. They must invest in novel industrial processes that leverage data and advanced digital technologies.

Conclusion

This article has introduced the Industrial Internet of Things, including its main use cases and business value potential for industrial enterprises. It has shed light on how embedded sensors, cloud/edge computing, and Artificial Intelligence provide a sound basis for optimizing production operations in directions that can improve production time, quality, and cost, while at the same time boosting employees’ safety and customers’ satisfaction. Follow-up articles will delve into more details about the technical architectures and technological components of Industry 4.0 applications, including tools and techniques for their development and deployment.

About the sponsor: Arduino Pro

Arduino Pro and Industry 4.0

Driven by the challenges outlined above, Arduino has recently created its Arduino Pro solution for Professional Applications. Arduino has a long tradition of providing popular open hardware solutions, along with a vibrant community of millions of users. Arduino Pro builds on this legacy to enable advanced users to build IIoT applications in flexible and cost-effective ways. It is an all-in-one IoT platform, which combines:

Hardware boards for industrial control, robots, and edge AI applications.

The Arduino Pro boards range from industrial-grade devices for battery-powered applications to tiny microprocessors that can execute embedded machine learning and TinyML applications. Arduino boards can equip legacy machinery with IoT capabilities, as a means of enabling brownfield IIoT deployments.

End-to-end connectivity solutions for deploying cloud-based applications.

Arduino Pro connectivity solutions are integrated with Arduino boards and support applications with connected devices on the go, even in cases where there is no reliable Wi-Fi coverage. Arduino solutions provide end-to-end security by design, based on the inherent security features of Arduino devices, such as on-board crypto authentication chips and their certified communications options.

Advanced development environments that enable low code application development.

Arduino development tools come in different flavors, ranging from cloud-based environments to command-line tools. They simplify the task of developing business logic for industrial applications based on simple, flexible, and instant access to the low-level capabilities of Arduino boards.

Ease of implementation and significant community support

Arduino Pro uses the Arduino IDE (Integrated Development Environment), which has an established community of millions of users. As embedded developers tend to favor C++, Arduino Pro enables embedded developers to engage with Industry 4.0 in a familiar language.

The Arduino Pro can be deployed for solutions in automotive, industrial automation, equipment manufacturers, and smart agriculture by optimizing processes, upgrading existing equipment, improving time to market, and developing new business models.

References:

1. S. El Hamdi, A. Abouabdellah and M. Oudani, "Industry 4.0: Fundamentals and Main Challenges," 2019 International Colloquium on Logistics and Supply Chain Management (LOGISTIQUA), 2019, pp. 1-5, doi: 10.1109/LOGISTIQUA.2019.8907280.

2. Itxaro Errandonea, Sergio Beltrán, Saioa Arrizabalaga. (2020) Digital Twin for maintenance: A literature review, Computers in Industry, Volume 123, 2020, 103316, ISSN 0166-3615, https://doi.org/10.1016/j.compind.2020.103316.

3. Bai, Yun & Sun, Zhenzhong & Deng, Jun & Li, Lin & Long, Jianyu & Li, Chuan. (2017). Manufacturing Quality Prediction Using Intelligent Learning Approaches: A Comparative Study. Sustainability. 10. 85. 10.3390/su10010085.

4. Psarommatis, Foivos & MAY, Gökan & Dreyfus, Paul-Arthur & Kiritsis, Dimitris. (2019). Zero defect manufacturing: state-of-the-art review, shortcomings and future directions in research. International Journal of Production Research. 58. 1-17. 10.1080/00207543.2019.1605228.

5. H. Kwon, H. Yoon and D. Choi, "Priority Adversarial Example in Evasion Attack on Multiple Deep Neural Networks," 2019 International Conference on Artificial Intelligence in Information and Communication (ICAIIC), Okinawa, Japan, 2019, pp. 399-404.

6. M. de Prado et al., "Robustifying the Deployment of tinyML Models for Autonomous mini-vehicles," 2021 IEEE International Symposium on Circuits and Systems (ISCAS), 2021, pp. 1-5, doi: 10.1109/ISCAS51556.2021.9401154