Compact, High-Speed Spectroscopy for Real-Time Applications: The FTIR Engine C16511-01

Hamamatsu Photonics introduces the FTIR Engine C16511-01, a state-of-the-art near-infrared spectrometer designed for rapid and accurate data acquisition in demanding industrial environments.

Spectroscopy technology is critical for numerous industries, facilitating precise analysis of physical, chemical, and structural properties through interactions between matter and infrared light. Hamamatsu Photonics introduces the FTIR Engine C16511-01, a state-of-the-art near-infrared spectrometer designed for rapid and accurate data acquisition in demanding industrial environments. Leveraging advanced optical interferometry, Ethernet connectivity, and a compact form factor, this instrument enhances real-time monitoring capabilities in sectors such as pharmaceuticals, food processing, and biotechnology. By addressing previous technological limitations, Hamamatsu’s innovation provides greater accuracy, reliability, and integration flexibility, significantly advancing the application of industrial spectroscopy.

Introduction

Optical spectroscopy is a technique that analyzes how light interacts with matter to determine its physical, chemical, or structural properties using wavelengths in the ultraviolet (UV), visible, or infrared spectrum. Increasingly, spectroscopy is essential in sectors such as pharmaceutical manufacturing, food processing, and biotechnology, where rapid and accurate real-time data acquisition is crucial for quality control and operational efficiency [1]. Responding to these industry demands, Hamamatsu Photonics has released the FTIR Engine C16511-01. It is engineered to overcome limitations of traditional spectrometers, including slow data processing, limited integration flexibility, and inadequate communication interfaces [2].

Current Challenges in Optical Spectroscopy

Traditionally, industrial spectroscopy faced substantial challenges, primarily involving complex instrumentation and limited data transfer speeds. Bulky equipment often cannot fit easily into crowded factory environments. Many traditional systems rely on USB connections, limiting data speed and reliability, which complicates rapid decision-making in industrial production [2]. These industrial diffractive spectrometers also face a critical trade-off between spectral resolution and measurement speed. FTIR spectrometers, however, overcome this compromise, delivering high spectral resolution simultaneously with high-speed data collection [2].

Moreover, environmental factors such as temperature variations, vibrations from machinery, and electromagnetic interference can affect optical components. These factors make it challenging to maintain consistently high wavelength accuracy. Precision alignment of mirrors and detectors also poses difficulties over extended operational periods, especially in environments where frequent calibration may be impractical. Uncalibrated measurements become unstable and degrade the quality of collected data, leading to less confident quality control outcomes.

Another significant issue is the variability in sample conditions and analyte concentrations, which can demand real-time monitoring. Bulky or sensitive spectrometers may have limited tolerance for environmental fluctuations, necessitating controlled laboratory-like conditions that are not always feasible in process lines [3]. Consequently, industrial facilities experience production slowdowns, higher operational costs, and elevated risk of noncompliant products. When high wavelength accuracy and stable data acquisition are not ensured, results can become inconsistent or erroneous, necessitating rework or scrapped batches, directly impacting a company’s competitiveness [4].

In short, the combination of physical hardware constraints, suboptimal communication interfaces, environmental stressors, and calibration complexities can all impede successful spectroscopic analysis [5]. Addressing these limitations is essential for safeguarding product integrity, optimizing resource usage, and enabling effective real-time decision-making in modern industrial ecosystems [1].

Introducing the FTIR Engine C16511-01

The FTIR Engine C16511-01 from Hamamatsu integrates advanced Fourier Transform Infrared (FTIR) technology within a compact, rugged enclosure optimized for industrial applications [1]. By utilizing Ethernet (GigE Vision) connectivity, this new instrument ensures significantly enhanced communication speed and reliability compared to traditional USB-connected spectrometers [1,2].

Advanced Optical Interferometer Technology

Central to the FTIR Engine C16511-01 is its Michelson optical interferometer, which includes a built-in light input section, beam splitter, fixed mirror, movable mirror (ϕ3 mm), and a high-performance InGaAs photodetector. This configuration precisely captures variations in light intensity signals caused by the position of the movable mirror. These signals are processed using a Fourier transformation, producing highly accurate optical spectra [1].

Additionally, the system features an integrated vertical cavity surface-emitting laser (VCSEL). A VSCEL is a specialized semiconductor laser that emits light perpendicular to the wafer surface, providing continuous, precise monitoring of the movable mirror’s position. This distinctive laser design ensures superior wavelength accuracy and thermal stability by producing a stable and narrow emission profile, which is critical for sensitive industrial processes requiring rigorous quality control. By delivering a consistent reference signal, the VCSEL minimizes measurement drift and enhances the overall precision of Fourier transform calculations, thus maintaining reliable spectral data throughout demanding industrial operations [1].

Detailed Technical Capabilities

High Signal-to-Noise Performance

With a signal-to-noise ratio exceeding 10,000, the device can reliably detect and quantify subtle variations in spectral data. This sensitivity ensures accurate measurements even in environments with inherent background noise, enabling precise detection of low-concentration analytes critical for many industrial processes [1].

High-Speed Data Acquisition

The FTIR Engine C16511-01 records spectra at a rate of 275 frames per second. This capability is crucial for capturing dynamic processes in real-time, essential for rapidly evolving reactions or high-throughput industrial environments where timely data is critical [1].

Ethernet Connectivity

The Ethernet (GigE Vision) interface provides rapid and reliable data transfer, fully compatible with Windows and Linux operating systems, offering easy integration with OEM equipment. It ensures robust, continuous performance even in electromagnetically noisy industrial environments [1,2].

Compact Form Factor

The compact design, measuring 68 × 124 × 66 mm and weighing approximately 580 g, facilitates integration into constrained or mobile industrial settings without sacrificing durability. This form factor enables installation in various operational configurations, including robotic or automated systems, where space efficiency is paramount [1].

High Wavelength Accuracy

The built-in VCSEL laser provides precise positional feedback of the movable mirror, maintaining consistent wavelength accuracy. This capability ensures reliable quantitative and qualitative analyses across multiple measurements, which is critical in regulatory-sensitive applications such as pharmaceuticals and food safety [1].

Broad Spectral Range

Covering wavelengths from 1100 nm to 2500 nm, the FTIR Engine enables comprehensive analysis across a wide variety of chemical compounds. This extensive spectral coverage supports diverse industrial applications, facilitating detailed molecular characterization essential for quality control and research [1].

Versatile Industrial Applications

The FTIR Engine C16511-01 is a versatile analytical tool supporting various industries. In pharmaceuticals, it enables rapid, non-destructive inspection of medicinal products, ensuring accurate identification and quantification of active pharmaceutical ingredients (APIs) and excipients. It also supports polymorphism studies essential for drug solubility, stability, and bioavailability, and quickly detects cross-contamination between production batches, preventing costly disruptions [5,8].

Within food processing and agriculture, the engine rapidly authenticates ingredients, detects contaminants, and evaluates nutritional profiles, providing immediate quality assurance. Its non-destructive nature and minimal sample preparation streamline routine testing, ensuring consistency and safety in food production [6,9].

Biotechnology industries utilize the FTIR Engine for real-time monitoring of biochemical reactions, gaining valuable insights into reaction dynamics, yield optimization, and purity control. It plays a vital role in downstream processing, verifying protein and enzyme purity, and preventing costly batch failures by identifying deviations early [7,10].

Additionally, the FTIR Engine significantly enhances recycling processes by rapidly identifying various polymers such as polyethylene, polypropylene, and polystyrene. Automated inline systems leverage its capabilities for efficient sorting of multi-layer plastics, improving recycling accuracy and supporting sustainable waste management [5,11].

User Benefits and Integration

The FTIR Engine C16511-01 provides significant operational advantages, including high precision and rapid measurements for improved decision-making and quality assurance. Its robust Ethernet connectivity ensures reliable, high-speed data transfer, reducing downtime and maintenance requirements. The compact design simplifies integration across diverse industrial setups, enhancing flexibility.

To further support customers, Hamamatsu’s FTIR Engine comes with intuitive evaluation software. This software facilitates streamlined data acquisition, real-time configuration, and spectral visualization. It logs extensive spectral data and supports automated batch processing. Additionally, detailed DLL specifications allow integrators to develop custom software modules using languages such as C++ or Python, tailored to specific analytical needs. These APIs seamlessly integrate with existing SCADA systems and synchronize with third-party sensors or actuators, significantly improving overall process control and operational efficiency [1].

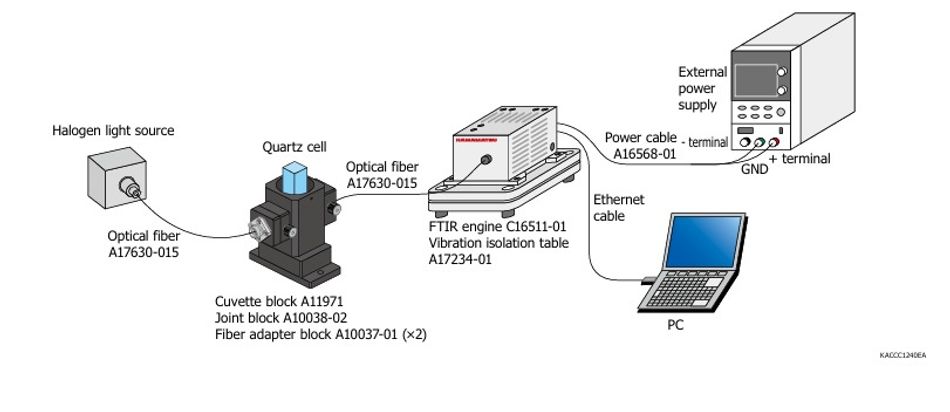

Additional Options and Accessories

Hamamatsu offers several accessories that further improve reliability and integration flexibility. Vibration isolation tables ensure measurement stability, specialized optical fiber cables minimize signal distortion, and flexible power options (12 V or 24 V) accommodate diverse industrial requirements. The FTIR Engine is also compatible with the L16462-01, a fiber-coupled diffused reflection light source designed for near-infrared applications. This light source enhances signal collection for diffuse reflectance measurements, improving data quality in in-line or remote monitoring applications. Together, these options ensure consistent data quality in demanding operational conditions [1].

Enhance Your Real-Time Monitoring Capabilities

The FTIR Engine C16511-01 offers high-speed, high-accuracy spectral data acquisition in a compact, industrial-ready design. With advanced optical interferometry, integrated VCSEL technology, and robust Ethernet connectivity, it supports reliable in-line analysis across a range of demanding applications—from pharmaceutical manufacturing to polymer sorting.

References

[1] Hamamatsu FTIR Engine C16511-01 Technical Documentation, Hamamatsu Photonics

[2] Hamamatsu FTIR Engine C15511-01 Technical Documentation (Previous Version), Hamamatsu Photonics

[3] Mitchell, S. (2020). "Calibration complexities in near-infrared reflectance technology for high-throughput lines." Journal of Applied Spectroscopy, 47(1), 11–15.

[4] Smith, J. & Wilhelm, K. (2021). "Transmission Bottlenecks in High-Volume Spectral Data Systems." Industrial Engineering Journal, 58(2), 89–97.

[5] FTIR Spectroscopy Testing and Analysis, Contract Laboratory: https://outsource.contractlaboratory.com/ftir-spectroscopy-testing-and-analysis

[6] Agilent Technologies, FTIR Applications in Food Testing: https://www.agilent.com/library/applications/5991-1246EN_AppNote_MM_FoodIngredients.pdf

[7] Mettler Toledo, FTIR Spectroscopy for Bioprocess Monitoring: https://www.mt.com/us/en/home/applications/L1_AutoChem_Applications/ftir-spectroscopy.html

[8] Huang, T., & Carter, S. (2022). "Advancements in FTIR-Based Contamination Detection in Pharmaceutical Manufacturing." Journal of Pharmaceutical Analysis, 34(3), 211–219.

[9] Rossi, L., & Martins, J. (2021). "Nutrient Profiling Using FTIR Spectroscopy in Food Production." Food Quality and Safety Journal, 17(4), 98–104.

[10] Pérez, M. & Clarkson, D. (2023). "Real-Time Downstream Process Monitoring with FTIR in Biotechnology." Bioprocess Engineering Quarterly, 45(2), 67–72.

[11] Tanaka, Y. & Basu, R. (2021). "Automated Inline FTIR Analysis for Multi-Layer Polymer Recycling." Journal of Sustainable Materials Engineering, 22(1), 13–21.