Siemens SIMATIC ET200SP I/O Modules

Modular Distributed I/O System for Control Cabinets

General

| Product Type | Power & Energy Solutions |

| Applications | Prototyping & Development |

| Key Features | distributed I/O system, IP20, Fit for Control Cabinets, -30 °C to 60 °C, Multi-Functional |

Technical Specifications

| System Type | Distributed I/O System |

| Protection Class | IP20 (Control Cabinet Installation) |

| Scalability | Multi-Functional, Scalable with a Wide Range of Modules |

| Installation Environment | Control Cabinet |

| Ambient Temperature | -30 °C to 60 °C (Extended Range) |

| Applications | Positioning, Load Control, Drive Controllers, Energy Management |

Overview

The SIMATIC ET200SP by Siemens is a distributed I/O system characterized by its multi-functional and scalable design, which includes a wide selection of modules. It is approved for an IP20 degree of protection and is intended for installation within a control cabinet. The system's design incorporates push-in terminals, which simplify both wiring and cable disconnection. Notably, its compact form factor is up to 50% narrower than that of other distributed I/O systems.

The modular architecture facilitates straightforward and tool-free station setup and cabling. A clearly structured identification system aids in both mounting and servicing. The system offers flexibility through expandability and the ability to quickly replace modules. ET 200SP stations can be configured connect to up to six controllers at the same time using three different Fieldbus systems on a single Ethernet backbone. It also integrates safety features to reduce engineering and wiring effort. These characteristics make the ET200SP suitable for distributed I/O architectures requiring efficiency, scalability, and reliability.

Features of SIMATIC ET200SP I/O Modules

The SIMATIC ET200SP is a modular distributed I/O system featuring a compact design, tool-free installation, and a wide range of modules. Its scalability and safety integration simplify engineering and wiring tasks. Let’s go through its features in detail:

Scalability and Modularity

The SIMATIC ET200SP I/O Modules constitute a multi-functional and finely scalable distributed I/O system. This modular design offers a large variety of modules, enabling flexible expansion and quick replacement of components. The system's design simplifies the station setup with tool-free assembly and easy cabling.

Physical Design and Protection

The system is designed for installation within a control cabinet and features an IP20 degree of protection. Its physical form factor is up to 50% narrower than other distributed I/O systems, which can be advantageous in space-constrained applications. The inclusion of push-in terminals simplifies the wiring and disconnection processes.

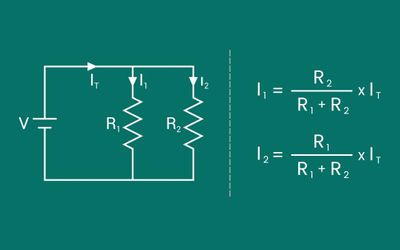

Integration and Communication

The system's design includes safety integration, which can reduce the amount of engineering and wiring required. This also leads to a reduction in the types and parts needed for implementation. The ET200SP is designed to accommodate a wide range of different communication paths, enhancing its versatility.

Identification and Extension

A structured identification system enhances clarity during mounting and servicing, thereby minimising installation errors. The ET200SP also supports simple extension, ensuring consistent performance across protection classes ranging from IP20 to IP65/67, making it adaptable to different environments.

Maintenance Flexibility

The modular design enables rapid replacement of individual modules without disturbing the overall system. This reduces downtime, simplifies servicing, and enhances flexibility when adapting the system to changing operational requirements.

Applications

The SIMATIC ET200SP I/O modules are designed for precise industrial automation tasks requiring accuracy and scalability. They are used in counting and measuring operations to monitor production flow and ensure quality control. In positioning applications, the modules support accurate movement control for machinery and robotics. They are also suited for weighing and dosing processes, ensuring consistent material handling in manufacturing lines. With cam and measuring input, the system enables high-resolution synchronization in motion control systems. Additional use cases include load control for managing electrical consumption, integration with drive controllers for motion systems, and energy management for optimizing power usage across operations.

Siemens offers a free tool for testing and documenting plant wiring of I/O stations, eliminating the need for a controller and programming PC.

Where to find it

Mouser Electronics

Mouser Electronics is a worldwide leading authorized distributor of semiconductors and electronic components.