Top 10 Causes of Magic Smoke

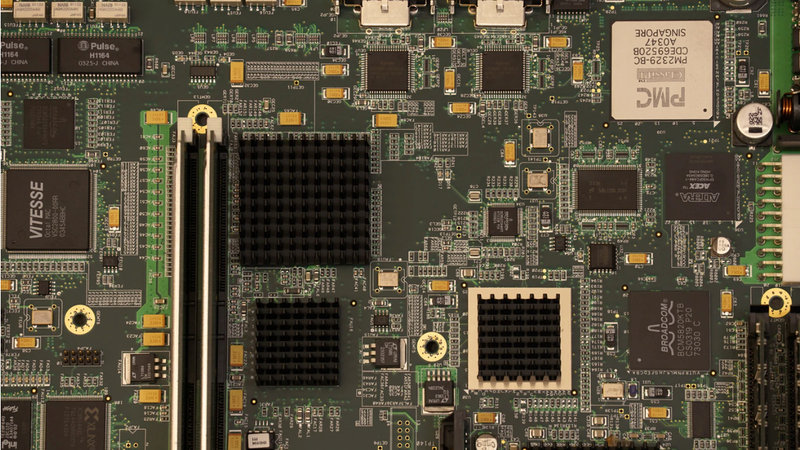

The excitement of seeing a new system operate for the first time is deflated when a component releases your arch-nemesis: magic smoke.

Magic smoke can kill the excitement of seeing a new system operate.

This article was first published on

macrofab.comTop 10 Causes of Magic Smoke

On occasion, the excitement of seeing a new system operate for the first time is deflating when a component releases your arch-nemesis – magic smoke. The system may not function if there is a critical error preventing operation. While this can be frustrating, there are several areas for design review that can mitigate this problem and should be included in your next project to achieve first success in the future. Let’s take a look at the top ten areas to prevent your boards from releasing magic smoke.

Make the Right Connections

Ahead of the system PCB fabrication tapeout, a detailed design overview for each component pin is needed. This includes not only power and ground pins, but also all the digital I/O, control, analog and do not connect (DNC) pins. The functional operation of each pin should be compared against the signal input device. The specified minimum and maximum voltage and current of each should be compared against the worst signal cases. DNC pins should be soldered to an open to maintain mechanical integrity. Complex design software tools should do this automatically, but the results will only be as good as the component library information that was input by a human. A final pin review often identifies subtle issues.

Take a Hard Look at the Mirroring

In an effort to make a component fit into a difficult location on a PCB, a layout engineer may often rotate and flip component decals to minimize the active routing area. Sometimes a component decal can be inadvertently mirrored. A true mirror of a component, without placement on an opposite PCB surface, will be assembly prohibitive. Componentlayout using multiple sides to a PCB can invert a component inadvertently. The layout tool should alert the user to this situation, but a final review of all components before PCB fabrication is often the best approach. Also, ensure that the pinout decal matches the component pinout to prevent library errors.

Showcase the Right Model

All components, both active and passive, come in a variety of functional variants. Package form factor, tolerance, speed rating, and power ratings are just some of the differences that can separate one similar component from another. Ensure that your BOM accurately describes the exact component variant that your design requires. Once the BOM is ordered, your contract manufacturer will verify that the received components match the BOM listing to be used within the PCB assembly. Many components look the same but have different electrical pinouts. A model difference in one component has the potential to cause the first system build to be non-operational.

Challenging Pitches

Narrow pitch Ball Grid Array (BGA) devices and Small Outline Transistor (SOT) components are efficient in minimizing system area. Resistors and capacitors smaller than 0201 dimensions are becoming more commonplace for new designs. However, without proper solder pad openings and spacing on the layout, their small solder footprint can lead to bridging and cold solder joints. A review of the solder screenprint for the system PCB should be completed against the assembly requirements to eliminate layout issues stemming from poor solder connections. Although layout tools should flag design rule violations for spacing issues, specific assembly-challenged areas may need to be added to your ruleset. Your CM can review the assembly equipment spacing capability against your design to mitigate these solder pitch issues.

Establish Limits

Each active component may need a current limit on its respective pins to prevent tri-state events that can draw excessive current. While many digital I/O and control signals offer internal pull-up and pull-down resistors, some legacy components do not. Normally, a high or low signal will be driven with the proper termination on the other end of the transmission line. However, if neither a high nor low is driven, the pin has the potential to be left floating in a logical unknown or tri-state. This case can pull unwanted current and power from the supply when an entire digital bus is left in this state. An external resistor that is tied to GND or supply may be needed for those components that do not offer internal terminations. A supply line to an active component may also need a current limiter to prevent a runaway thermal situation where the component draws excessive current beyond its capability.

Poka-Yoke Protection

Additional protection circuitry may be required to protect the system from surge current type events that could damage the electronics. Whether the surge occurs at first power-up or is a discrete abnormal event, the intent is to protect the system from the offending signal. Often, this can be done with Zener diodes and other clamping devices. If the assembly is a sub-system within a larger more complex system, the connectors and any cable interfaces should have a Poka-Yoke strategy to prevent misinsertion. This approach creates a fool-proof method to ensure that the system is properly connected. An everyday example of this is the three-prong electrical outlet plug in the USA that only affords one orientation for proper insertion.

Review Failure Modes

A complex system may have many potential ways that it could fail, often including some that are not intuitive. Many organizations require a complete Design Failure Mode Effects Analysis (DFMEA) review to determine and review all these modes of operation that could fail. This is generally a good practice if for nothing else than to identify weaknesses in the design. After identification, each failure mode will be scored based on its severity, probability of occurrence, and method of detection. A risk priority number can be calculated to determine the most impactful failure types. The worst offenders should be addressed within the design or test methods to improve the system performance and reduce the opportunity for smoke.

Address the Outside Concerns

An electrical system is not self-contained as it must accept interference from the external environment. A power surge or ground bounce has the potential to damage the system. Large RF signals may damage a radio receiver that is designed only to observe small signals without the proper filtering. Consider all of the worst-case signals during the system design – internal to the board, and incoming from off the system. Part of the system DFMEA review should ask the design team – “What outside electrical interference could cause this system to fail”?

Identify Initial Conditions

The initial start-up condition for a system can often be neglected. The steady-state operation is the most valuable and the mode that is given the most attention. However, this initial operation time may be the most severe, electrically, to the design. A proper review should model all the transients and inrush current at turn-on. It is during this stage that capacitors first charge and transient spikes could be observed at the internal component pins. Microcontrollers enter a boot sequence where memory is read and initial activity takes place. The current consumption during this phase is higher and must be modeled during the design phase of the project. This unusual, but predictable, power activity could create scenarios where component maximum tolerances are exceeded.

Inspect the Corners

While nominal system conditions are pleasing for performance reasons, the minimum and maximum scenarios cannot be ignored since they will be a required use case. The complex system design must consider all of the corner cases of elevated supply, extreme temperatures, and environmental conditions such as humidity and EMC, maximum loading and computation. In fact, if the corner operation cases perform well, it may preclude the need to test the system at a nominal condition.

Keep the Smoke Inside

The first verification step for a new system is to turn it on and check for unwanted smoke. Inadvertent errors can cause issues at this first step. Properly review the system requirements, layout, BOM, and corner cases to mitigate these issues. Work with your CM to understand minimum pitch and assembly challenges in advance of fabrication. On your next project, make sure to keep the smoke inside the components and don’t let it out in the open.