Overcoming the challenges of 3D scanning

Sprays that enable the accurate scanning of shiny or transparent materials enable 3D scanning to fulfill its potential.

Tags

3D scanning is used in a variety of applications, including prototyping, quality control, and reverse engineering. However, this cutting-edge technology is hampered by the inability of scanners to capture objects with shiny or transparent finishes and those with deep-pocketed geometries. Improvements in scanner technology alone cannot overcome these challenges. For 3D scanning to be as fast and agile as it promises, the use of sprays that temporarily matte the object’s surface is a reliable and high-performance solution.

Why is 3D scanning so important?

The technology of 3D scanning began in the 1960s when cameras, lights, and projectors were used. In the past, 3D scanning wasn’t always used for engineering. Instead, it was often used to film CGI and to help create special effects. In cases where the early scans were used for manufacturing, engineering, or medical science, the process was long, less accurate, and labor-intensive.

With the introduction of personal computers in the 1980s, better scanning hardware, and moving from four to six degrees of freedom with the scanning arms, the technology improved. The adoption of CAD in most technical industries and the development of the software that assists scanners in producing not just a point cloud but a continuous surface, with the correct underlying mathematical curvature models, also pushed the technology forward considerably.

Currently, 3D scanning is used in many industries. The ability to reverse engineer an object’s surface is a large driver of technology, particularly in the automotive industry. 3D scanners are used to verify geometrical accuracies in bodywork, structures, and when panels and assemblies are put together. When native CAD of a surface or structure does not exist or isn’t readily available, 3D scanners are used to generate those surfaces. For example, if there is a bespoke car that needs to be analyzed, its geometry must first be digitized. Only after 3D scanning and CAD cleanup can the vehicle’s shape be analyzed, modified, and used for other optimization protocols (e.g., CFD or FEA).

The challenges of scanning shiny and transparent objects

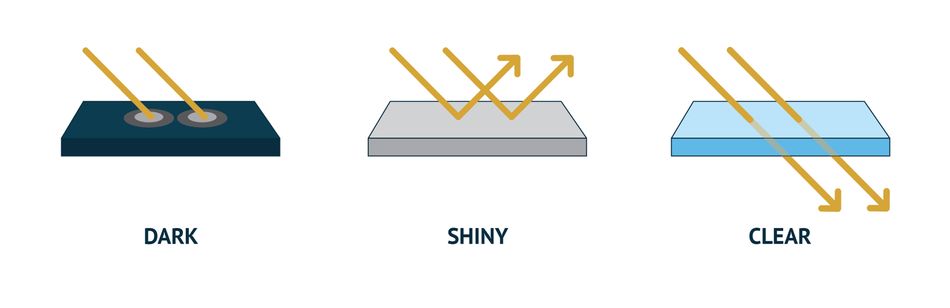

Scanning technology has rapidly evolved over the last decade, and now handheld and automated scanners can produce high-resolution scans seamlessly. However, objects with shiny, transparent, or deeply pocketed surfaces still prove very challenging. This is because these surfaces cause the light to be distorted in such a way that it interferes with the data acquisition process. These types of materials affect how the 3D scanner views the object and consequently affect how it takes the images. Figure 1 shows how light reacts to different surfaces.

Addressing scanning challenges

For accurate scanning, the surface of shiny and transparent materials must be modified in some way. Over the years, several different solutions have been tried, including covering the object in tape, which is both time-consuming and expensive; to using a chalk-based spray that whitens the whole object enabling light to be effectively absorbed for scanning. While effective, these sprays create a difficult-to-clean mess. The spray is also potentially lethal to delicate equipment, including the scanner itself. Recent advances have resulted in specialized sprays that leave no discernible coating.

AESUB Sprays

AESUB scanning sprays have been developed as a no-contamination range of sprays that remove the challenges of 3D scans across industries. AESUB produces scanning sprays that enable more seamless use of spray within workflows. The vanishing sprays are dry to touch and sublimate after a few hours. The sprays are applied either by hand using a traditional spray can type application, via a spray gun, or via an automated robotic spray head. The sprays create a homogeneous matte layer of material that provides perfect optical scanning conditions. The surface coating provided by the spays is typically between eight and 15 μm.

The uniform coating eliminates common issues with surfaces that are notoriously difficult to scan:

- Eliminates transparency or reflective properties of materials so that the light of the 3D scanner is reflected back as required.

- When the geometry has deep pockets (e.g., recesses for bolts, or has a void where another part will be attached/inserted).

- Reduces color or surface quality irregularities on the same part/assembly (e.g., an entire vehicle will have many different types of surfaces and surface qualities).

The AESUB product series consists of three vanishing sprays (AESUB blue, AESUB orange, and AESUB green) and one semi-permanent spray (AESUB white). AESUB blue and orange are provided in aerosol cans and differ in terms of sublimation time. AESUB green is provided as bulk solution for spray guns and automated spraying of large-scale objects. AESUB white is in turn a semi-permanent scanning spray. Unlike other pigment sprays, AESUB white is free of titanium dioxide, associated with cancerogenic incidents through inhalation by the European Chemicals Agency.

The vanishing AESUB range is particle-free, meaning that the spray can be used in environments where cleanliness is essential. Laboratories, clean rooms, and other highly particular manufacturing environments can safely use the spray without any worry of it damaging sensitive equipment (including the 3D scanner). Since the spray evaporates after scanning, there is no need for the otherwise time and cost-intensive cleaning process.

Applications for AESUB sprays

Reverse engineering

Reverse engineering is when an object is recreated using a source model. This method of production is particularly valuable when a part is difficult to source, or the price to replace is astronomical. To reverse engineer something you first need as much information about the source object as possible. Obviously, 3D scanning is now the best tool for this. In the video below the host demonstrates how scanning different objects enable him to quickly create a 3D model of the object that can then be replicated using 3D printing or other manufacturing methods.

Automotive engineering

In order to scan the surface of a complex automotive front headlight assembly, a scanning spray must be used to eliminate the transparency of the surface. In addition, if the rear of the part must also be scanned, reflective plastic components will also need to be sprayed. Engineering firms even have dedicated robots that will spray AESUB green uniformly before initiating another robot to automatically scan the geometry.

Rapid asset capture

Rapid asset capture is gathering surface data, CAD, measurements, or other material information of objects or systems in a very short period of time. Rapid asset capture might be used to assess a product or system for purchase, maintenance, or inventory.

Using scanning spray ensures high-quality fast scans. Reducing the potential error saves time and money. Consider scanning a car door that has transparent glass, chrome window surrounds as well as highly reflective painted metal surfaces. Without using a spray, quality data cannot be guaranteed and several scans of the part might be needed to gather enough information to form the 3D model. In the case study video below, the adding of the scanning target stickers is seen immediately after the spray is applied.

Summary

3D scanning is an important engineering technology, especially in automotive engineering where surfaces are often a complicated mix of matte, shiny and transparent. The use of 3D scanning sprays ensures that there is a matte, uniform coating to improve the accuracy of the scanned surface. AESUB is helping 3D scanning unlock its potential across engineering industries by creating products that specifically address these roadblocks.

About the sponsor: AESUB

AESUB is a new series of scanning sprays that help to digitize reflecting and transparent surfaces and evaporates after the 3D scanning. The sprays are easy to apply, ensuring faster, more efficient, and highly accurate 3D scanning

Tags