Tagged with

laser scanners

ORGANIZATIONS. SHAPING THE INDUSTRY.

Latest Posts

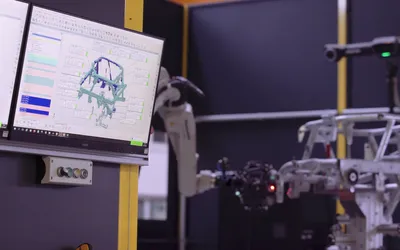

Do you have confidence in your 3D measurements? Are you certain they are accurate, repeatable, and reliable?

Do you ever question the accuracy and reliability of your quality control (QC) process? Do you ever doubt the quality of your measurement setup, especially if you are a non-expert in 3D scanning?

3D Scanning vs Manual Techniques: A Comparison of Their Effectiveness in Evaluating Large and Curved Surfaces

Creaform's non-destructive surface evaluation solution for the pipeline industry has received valuable feedback since its launch last year.

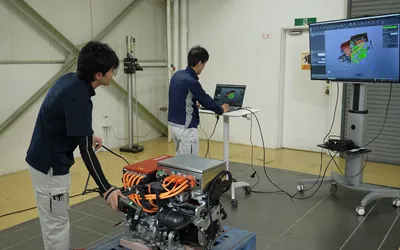

Electric Dream: The Booming Popularity of Electric Vehicles and What It Means for Automotive Part Manufacturers

Based on the latest International Energy Agency (IEA) projections (featured in the newest edition of the Global EV Outlook), the share of electric vehicles (EVs) in the overall car market has risen from around 4% in 2020 to 14% in 2022 and is set to increase further to 18% in 2023.

The shipbuilding industry is a critical component of any country’s infrastructure and economy. However, the process of ship construction, particularly the installation of pipes throughout the hull, is challenging and cumbersome. This is due to the segmented construction method adopted in shipbuilding, which often leads to deviations in the hull production process, making it difficult to accurately arrange and install pipes.

Ålö Agricultural Machinery (Ningbo) Co., Ltd, a wholly owned subsidiary of Ålö, is a leading manufacturer of loaders and implements for agricultural tractors. With production facilities in four countries and customers in over 50, Ålö holds approximately 30% of the world market for tractor loaders exceeding 50 hp. Since 2020, the company has been part of the JOST Group, a renowned manufacturer of safety-critical systems for commercial vehicles.