Tagged with

Injection Molding

ORGANIZATIONS. SHAPING THE INDUSTRY.

RapidDirect

Industrial Machinery Manufacturing

Custom parts manufacturing, from rapid prototyping to mass production.

13 Posts

FACTUREE – The Online Manufacturer

Manufacturing | Procurement

The digital all-in-one solution for effortless procurement of custom parts

12 Posts

View more

Latest Posts

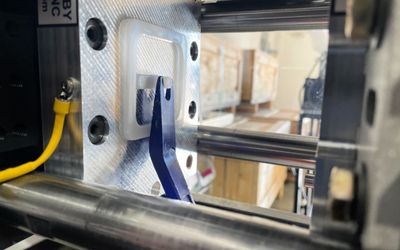

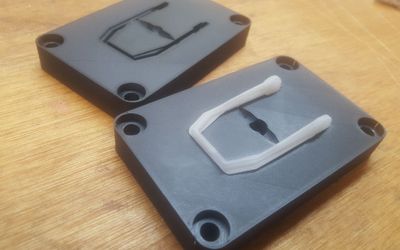

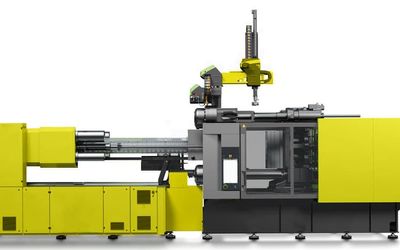

Injection molding is an invaluable process for creating plastic parts. This process is fast, cheap, and helps create vast volumes of identical objects. One of the most significant advantages of injection molding is the natural surface finish of molded parts. Even without any injection molding surface finish or post-processing treatment, molded parts have smooth surface finishes suitable for many end uses.

The injection molding cost is a common focus of plastic product manufacturers who use the process. It is an agglomeration of different factors and elements, and understanding such factors and elements plays a critical role in optimizing the cost of any project. As a result, this article breakdown everything you need to know about how much injection molding cost and how you can optimize it for your project.