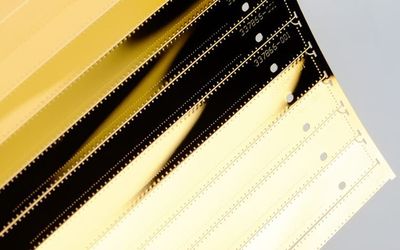

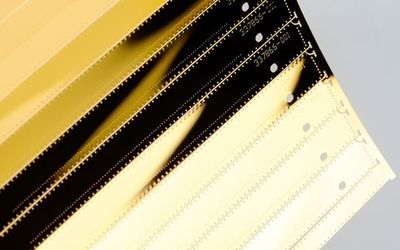

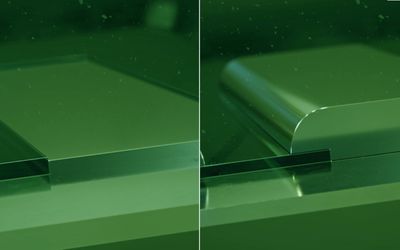

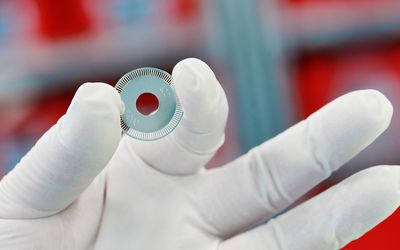

Electroforming is an Additive Manufacturing process specialized for the production of high-precision metal parts. Nickel, due to its expansive range of mechanical properties, aesthetic appeal, and resistance to corrosion, has become the most widely used material for this process. It not only enables the reproduction of extremely fine details but also permits the deposition of materials with high hardness. Electroforming technology allows depositing metal alloys to tailor specific material properties like mechanical or thermal characteristics.

Tagged with

electroforming

ORGANIZATIONS. SHAPING THE INDUSTRY.

Latest Posts

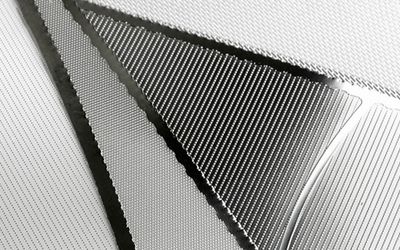

Veco’s unique Advanced Lithographic Electroforming process also referred to as Advanced Photo Electroforming, promises a move towards the frontier of precision engineering, incorporating micro precision, complex features, and freedom of design, all of which empower next-gen innovations across industries facing the challenge of miniaturization. This blog introduces 5 reasons to choose Electroforming in terms of freedom of design.

Pushing the Boundaries of Electroforming: Advanced Lithographic Electroforming and LIGA Processes explained

Compared with LIGA Electroforming technologies such as UV LIGA and X-Ray LIGA processes, Advanced Lithographic Electroforming is the most ideal process from prototyping to mass production.

The making of micro-precision nozzle plates: 3D Printing, Laser Cutting, Micro Milling, Micro Punching, and Electroforming compared

Micro-fabricated nozzle plates are used in various industries, such as inkjet printing, medical devices, and flow control. Manufacturing these nozzle plates requires precision and accuracy to achieve the desired performance. Several production technologies can be used to manufacture micro-fabricated metal nozzle plates, such as 3D printing, Laser Cutting, Micro Milling, Micro Punching, and Electroforming. In this article, we will introduce these production technologies, and illustrate how to find your preferred process for the production of micro-fabricated nozzle plates based on key features such as precision, customization, scalability, and material compatibility.

Harnessing the potential of micro precision: how Electroformed micro nozzle plates empower applications across industries

The world of precision technology is constantly evolving, and one of the innovations that have gained significant attention in recent years is the development of micro-fabricated metal nozzle plates. These tiny, intricate components are revolutionizing industries across the board, with various applications in fields like Inkjet Printing, Medical, and Flow Control. In this article, we'll explore the key features of these nozzle plates, their applications, and how they empower important industry applications.

Inkjet nozzle plates are one of the most important components of inkjet print heads, as the quality of the nozzle plates directly determines the resulting printing performance of the whole system. This article introduces what an inkjet nozzle plate is, how this important component works, and how it is manufactured.

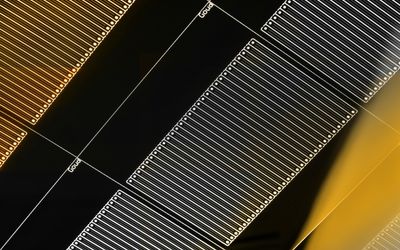

Inkjet Printing for Solar Cell Manufacturing: How Electroforming is empowering the photovoltaics industry moving forward

Inkjet printing is an extremely versatile, non-contact process that involves jetting tiny ink droplets to facilitate direct printing. It has seen a surge of new applications in fields including electronics, life science, optics, and PV.

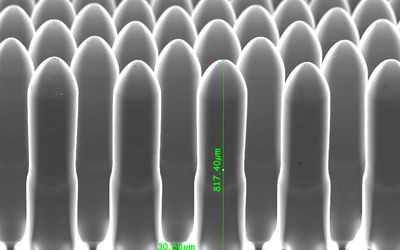

Electroforming is an additive manufacturing process specialized for the production of high precision metal parts. Its uniqueness is that you can grow metal parts atom by atom, providing extreme accuracy and high aspect ratios. Typical precision of a electroformed part goes down to 1 to 2 μm, which is beyond what most other manufacturing technologies can reach.

Micro Solutions for Macro Challenges: Electroforming Applications in Energy, Medical, Food, and Beyond

Applications for electroforming are enabling innovation in everything from satellites to water filtration.