Tagged with

3d scanning

ORGANIZATIONS. SHAPING THE INDUSTRY.

SHINING 3D

3D Scanning & 3D Inspection

SHINING 3D is the global 3d digitiziting technology solution provider, empo...

10 Posts

Scanology

3D Measurement & Digitization

SCANTECH is Global leader in 3D solutions, specializing in metrology-grade ...

Latest Posts

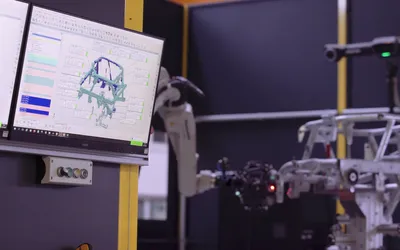

Vehicle manufacturing company uses 3D scanners to increase design quality and optimize engineering times

The use of the Go!SCAN SPARK and VXmodel leads to significant improvements in the internal processes when carrying out projects at the Swiss company Sutter AG.

Electric Dream: The Booming Popularity of Electric Vehicles and What It Means for Automotive Part Manufacturers

Based on the latest International Energy Agency (IEA) projections (featured in the newest edition of the Global EV Outlook), the share of electric vehicles (EVs) in the overall car market has risen from around 4% in 2020 to 14% in 2022 and is set to increase further to 18% in 2023.

The shipbuilding industry is a critical component of any country’s infrastructure and economy. However, the process of ship construction, particularly the installation of pipes throughout the hull, is challenging and cumbersome. This is due to the segmented construction method adopted in shipbuilding, which often leads to deviations in the hull production process, making it difficult to accurately arrange and install pipes.

Ålö Agricultural Machinery (Ningbo) Co., Ltd, a wholly owned subsidiary of Ålö, is a leading manufacturer of loaders and implements for agricultural tractors. With production facilities in four countries and customers in over 50, Ålö holds approximately 30% of the world market for tractor loaders exceeding 50 hp. Since 2020, the company has been part of the JOST Group, a renowned manufacturer of safety-critical systems for commercial vehicles.

National Steel Car is a leading railroad freight and tank car manufacturer. Based in Hamilton, Ontario, Canada, and founded in 1912, the company develops and produces over 76 model variations of freight and tank cars for railroad, agriculture, chemical, construction, metal, energy, and financial/leasing companies in Canada and the United States.

Developing a new type of train that could transport luxury tourists from Tokyo to mountain resorts, such as Hakone and Mount Fuji, and beaches, such as Odawara and Enoshima, in less time. That was the Odakyu Electric Railway’s mission when the company undertook the design of the Romance Car in 1957.