Ultimaker Method XL 3D Printers

Production-grade 3D printing quality, suited for connected 3D printing ecosystems.

Technical Specifications

| Technology | Fused Deposition Modeling (FDM) |

| Integrated Air Filter | HEPA and carbon filters |

| Connectivity | USB, LAN, Wi-Fi |

| Build Plate | Flexible build plate up to 105 degrees Celsius |

| Software | CloudPrint |

| Supported OS | Windows, MacOS |

Overview

The printer connects to the secure and reliable 3D printing ecosystem, producing highly accurate designs via the CloudPrint software. The software comes with the Method 3D printers, ensuring a seamless workflow from CAD design files to the finished products. The printer is designed to cater to the needs of the industry, enabling larger designs to finish quicker and at a higher precision.

Design with Engineering Grade Materials

Method XL 3D printers provide an extended range of printing materials, breaking the monotony of 3D designs. Designers can print manufacturing parts and production tools thanks to engineering-grade materials.

The design environment is pretty simplified and easy to use. Thanks to features like flexible build plates and high-precision hardware, it is possible to repeat the designs and achieve a consistent output. Hence, it supports batch production of engineering-grade materials. Moreover, thanks to the CloudPrint management system, the Method XL printers can run glitch-free 24/7, allowing designers to print and walk away as the machine takes care of the design. Moreover, the software support allows users to connect to a network of multiple 3D printers, further easing the printing process. The design files are easily transferable over the internet or USB devices.

Extra Large Build Volume with Advanced Printing Supports

Typically, 3D printers are faced with a design limitation that restricts the printing of large-sized materials. Method XL printers have ample space to print more oversized industry-grade products. The 3D printer features a 12 x 12 x 12.6 inches build volume, allowing the seamless printing of enlarged elements with any engineering-grade material.

There is an ultra-rigid printing frame that ensures less flexing and helps deliver consistent results over a large batch of printed designs. It also contributes to a higher success rate for each print cycle, reducing failure and delivering consistent and reliable results.

The internal print mechanism features a precisely temperature-controlled environment. A heated plate and an actively heated chamber deliver a consistent and stable printing environment. Eventually, it produces stronger, even, and accurately sized parts, whether big or small.

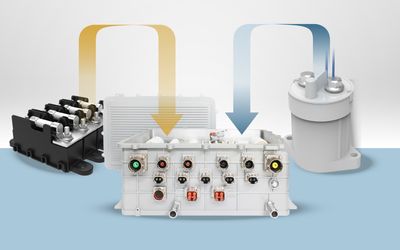

The water-soluble supports also enable easy and clean production of printed files. As a result, the method XL 3D printer can be an excellent option for printing production tools and manufacturing parts that become a part of larger systems.

Moreover, five-in-one modular extruders allow a quick changeover between material groups and filaments. The flexible build plate heats up to 105 degrees Celsius, allowing perfect adhesiveness for the initial layers that ensure a firm base for the design.

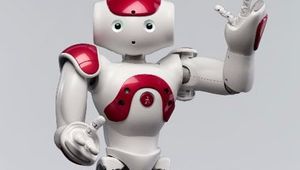

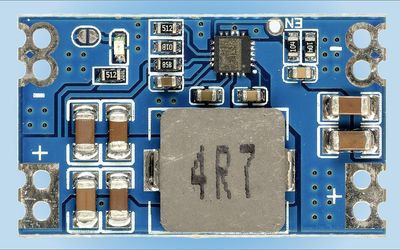

With extra printing space and support for multiple design materials, the Method XL 3D printer can be a viable option for printing parts for educational and research applications involving electronics, robotics, and modular design.