3D-Fuel Pro PCTG TDS

High Performance, UV Stable, Co-Polyester 3D Printing Filament

General

| Product Type | 3D Printing & Fabrication Tools |

| Applications | 3D Printing & Manufacturing |

| Key Features | co-polyester, 35× greater impact toughness, 90% light transmittance, 40+ color options |

Technical Specifications

| Specific Gravity | 1.23 |

| Tensile Strength (Yield, Break) | 44 MPa, 46 MPa |

| Elongation (Yield, Break) | 4.4%, 220% |

| Flexural Modulus | 1,600 MPa |

| Izod Impact Strength | 860 J/m (ASTM) / 93 kJ/m² (ISO) |

| Heat Distortion Temperature (0.455 MPa) | 74–76°C |

| Glass Transition Temperature (Tg) | 84°C |

| Light Transmittance | 90% |

| Applications | Functional Parts, End-Use Components, Robotics, Prosthetics & Orthotics, Oil & Gas |

Overview

The 3D-Fuel Pro PCTG filament is a co-polyester engineered as a performance upgrade over PETG for demanding 3D printing applications. It delivers up to 35× greater impact toughness, improved chemical resistance, and enhanced UV stability compared to conventional PETG. With a glass transition temperature of 84°C and a heat distortion temperature of 74/64°C at 0.455 MPa, it withstands elevated operating conditions. The material maintains exceptional clarity with 90% light transmittance, making it suitable for transparent or aesthetic parts.

The mechanical testing shows a tensile strength of 44–46 MPa, elongation at break of 220–340%, and an Izod impact strength of 860 J/m (ASTM) or 93 kJ/m² (ISO), reflecting its toughness. Pro PCTG also absorbs moisture at a slower rate than PETG, supporting easier storage and processing. The filament prints reliably without an enclosure, simplifying setup, and is offered in 40+ color options for single or multi-material printing systems.

3D-Fuel Pro PCTG TDS Features

3D-Fuel Pro PCTG is a co-polyester material designed for demanding 3D printing applications, offering 15–35 times greater impact toughness than PETG, superior chemical and UV resistance, and greater clarity. It is less moisture-sensitive, maintains better layer-to-layer bonding, and prints reliably with minimal warping. Let’s go through its features in detail:

Mechanical Performance

Pro PCTG exhibits high impact toughness, up to 35× stronger than PETG, making it suitable for demanding functional parts. It achieves tensile strength of 44–46 MPa, elongation at break of 220%, and a flexural modulus of 1,600 MPa, making it suitable for functional parts, snap-fit assemblies, and end-use components. Improved layer bonding is achieved when printed at optimized speeds, ensuring structural reliability.

Thermal Properties and Print Settings

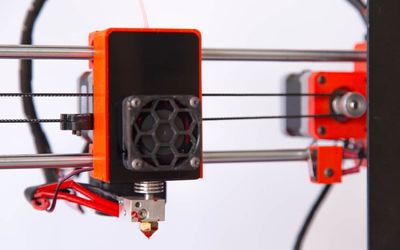

With a glass transition temperature of 84°C and heat distortion temperature of 74–76°C (0.455 MPa), Pro PCTG withstands temperatures about 5°C higher than premium PETG. Field tests show printed parts remain stable under direct sunlight and dashboard-level heat, where PETG and PLA typically soften. Recommended print settings include a nozzle temperature of 260–280°C, a bed temperature of 70–80°C, and print speeds ranging from 60 to 250 mm/s. Pro PCTG does not typically require an enclosure for printing.

Chemical and Environmental Resistance

Pro PCTG is more resistant to UV degradation and chemical exposure than PETG, with weathering tests underway against PETG and ASA. Its slower moisture absorption rate (about one-third that of PETG) helps keep spools drier for longer, improving storage stability. Customers also report higher lubricity, describing it as having a waxy feel that prevents parts from sticking, making it superior for mechanical linkages, pivots, and sliding features.

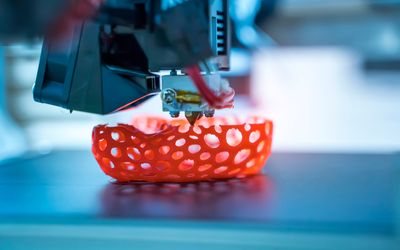

Optical and Color Performance

The filament achieves 90% light transmittance, supporting applications such as clear parts, lenses, and light guides. Its UV stability reduces haze and discoloration over time. Pro PCTG is available in 40+ colors, including clear, four translucent options, six toolbox-matched shades, matte black, and glitter-filled blends. This wide range makes it versatile for multi-colour printing systems, such as the Bambu Lab AMS, Prusa, Creality 3D, Anycubic, FlashForge, and Elegoo.

Applications

The 3D-Fuel Pro PCTG filament is suited for applications requiring high toughness, thermal stability, and chemical resistance. Its mechanical strength and elongation make it effective for functional parts and end-use components where impact durability is critical.

In robotics, Pro PCTG supports precise, load-bearing, and moving assemblies. For prosthetics and orthotics, the balance of strength and flexibility provides reliable performance under repeated use. In oil and gas environments, enhanced chemical resistance extends usability for structural and protective elements. The material also enables snap-fit assemblies, where high elongation at break and strong layer bonding ensure secure, repeatable connections without fracture or deformation.