Revolutionizing Pipeline Inspection: The Power of the ROCK 3 Compute Module

Explore the transformative potential of the ROCK 3 Compute Module in revolutionizing pipeline inspection. Discover the power and versatility of this innovative solution, designed to enhance safety, efficiency, and operational excellence in infrastructure maintenance.

Technology plays an instrumental role in ensuring the safety and efficiency of pipelines across various sectors, from domestic to commercial and mining. As industries strive for more robust solutions, introducing smart pipeline inspection technologies marks a significant leap forward.

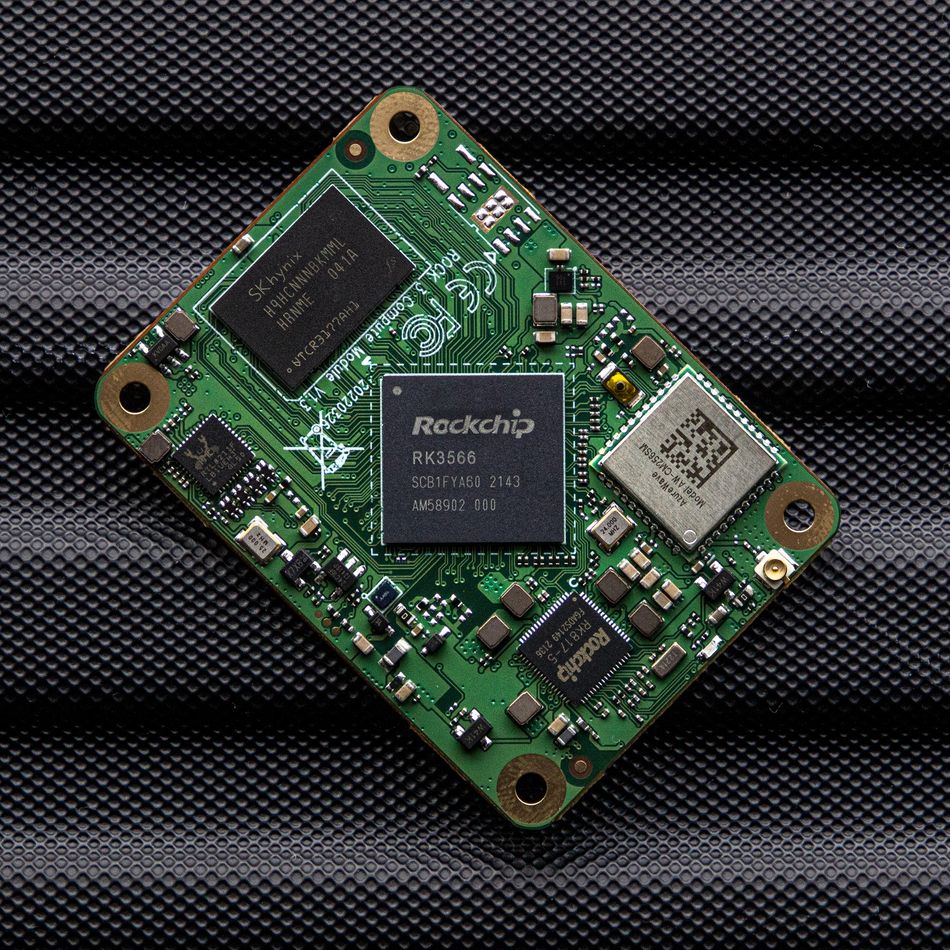

At the heart of this innovation is the OKdo ROCK 3 Compute Module (CM3), a powerful tool designed to elevate the precision and reliability of pipeline inspections. The ROCK 3 Compute Module (CM3) is an innovation in smart pipeline inspection. Developed through the collaboration of OKdo Technology and Radxa, the ROCK 3 CM3 display the intersection of advanced technology and practical application.

OKdo ROCK 3 Compute Module is a compact yet powerful system-on-module (SoM) that leverages the Rockchip RK3566 System on Chip (SoC). Its capabilities are not just limited to raw performance but extend to wireless connectivity, with WiFi® 5 and Bluetooth® 5.0, making it an ideal candidate for remote and autonomous pipeline inspection systems. These systems can perform detailed monitoring and predictive maintenance, fundamentally transforming the approach to pipeline management and setting a new standard for operational excellence.

In this article, we will dive deeper into how the ROCK 3 compute module is changing how pipeline inspection systems are built and introducing immense precision and cost benefits with a wide range of applications.

The Challenge of Pipeline Inspection

The challenge of pipeline inspection is multifaceted, evolving with the advancing infrastructure demands and technological capabilities. Pipelines, crucial for transporting natural gas, petroleum products, and other energy resources, face numerous challenges throughout their lifecycle. These challenges stem from various sources, including environmental conditions, the complexity of the pipeline systems, and the physical and operational stresses they endure.

Accessibility Issues

Pipeline networks are often situated in environments with significant accessibility challenges. These include subsea locations, remote areas, and locations with extreme weather conditions, making routine inspections difficult and costly. For instance, the depth of subsea pipelines complicates the delivery of well-proven inspection technologies without resorting to expensive equipment and procedures.

Continuous Monitoring Needs

The ongoing integrity of pipelines is critical to preventing leaks, ruptures, and other failures that can lead to environmental damage, economic losses, and safety hazards. Continuous monitoring is essential but challenging due to the extensive lengths of pipelines and the difficulty of accessing many sections. Digital twin technology and remote monitoring developments are promising but require complex data management and interpretation.

Risk of Human Error in Detecting Faults

Human error in detecting faults remains a significant risk in pipeline inspection. This risk is exacerbated by the reliance on complex inspection techniques that require specialised knowledge to interpret. Advanced non-destructive testing (NDT) methods, such as magnetic flux leakage (MFL), ultrasonic testing (UT), electromagnetic acoustic technology (EMAT), and eddy current testing (EC), have been developed to address this. These methods, employed through Pipeline Inspection Gauges (PIGs) or un-peggable robotic inspection systems, help mitigate human error but also introduce challenges in data management and analysis.

Inspecting and maintaining pipelines are critical yet challenging tasks that require a sophisticated blend of technology, human expertise, and continuous innovation.

The ROCK 3 Compute Module (CM3), developed by OKdo Technology in collaboration with Radxa, represents a significant advancement in embedded computing solutions. This compact module is specifically engineered for various applications, from digital signage and smart home automation to complex industrial processes and pipeline inspection technologies.

The key features of the ROCK 3 Compute Module (CM3):

Rockchip RK3566 SoC: A powerful System on Chip featuring a quad-core Arm® Cortex®-A55 CPU, tailored for efficient processing and capable of handling multitasking and demanding applications.

Memory: Up to 4GB LPDDR4 RAM, ensuring smooth operation and quick data handling, essential for efficiently processing large volumes of data.

Storage: Up to 32GB eMMC storage, offering substantial space for operating systems, applications, and data storage, enhancing its versatility in various embedded solutions.

Wireless Connectivity:

WiFi® 5: Allows for seamless internet and network connections.

Bluetooth® 5.0: Facilitates easy communication with other devices and sensors, which is particularly beneficial for IoT (Internet of Things) applications.

Compact Design: Dimensions of 55mm x 40mm, making it highly adaptable for integrating a wide range of design frameworks.

Versatility and Applicability: The module's capabilities make it suitable for various applications, from IoT devices to complex industrial systems, expanding its utility in the modern technological landscape.

The comprehensive feature set of ROCK 3 CM3 shows its capacity to revolutionise various applications by offering a robust, versatile, and efficient computing solution that caters to the evolving demands of the technology and innovation landscape.

A Hypothetical Smart Pipeline Inspection Solution

Design and Functionality

This hypothetical smart pipeline inspection system, leveraging the ROCK CM3 module, could revolutionise managing pipeline integrity. The system could be designed to include a range of sensors capable of detecting leaks, corrosion, and other anomalies that may compromise pipeline integrity. Additionally, integrating a high-resolution camera would enable visual inspection, allowing for a detailed examination of the pipeline's internal surfaces. These components could work in concert to provide a comprehensive assessment of pipeline health, identifying potential issues before they become critical failures.

Data Processing and AI Capabilities

The ROCK CM3, with its powerful Rockchip RK3566 System on Chip (SoC), Quad-core Arm® Cortex®-A55 CPU, and Arm Mali™-G52-2EE GPU, is exceptionally well-suited for advanced data analysis and AI-driven decision-making processes. Its processing power allows for the implementation of sophisticated AI algorithms capable of real-time fault detection and predictive maintenance strategies. This could significantly enhance the inspection system's efficiency, enabling it to analyze vast amounts of sensor and camera data on the fly to identify subtle indicators of wear, corrosion, or leaks that might be invisible to the human eye. The module's Neural Processing Unit (NPU) supports deep learning frameworks like TensorFlow and PyTorch, facilitating the development of custom AI models that can improve over time through machine learning techniques.

Connectivity and Remote Monitoring

With built-in WiFi 5 and Bluetooth 5.0 capabilities, the ROCK CM3 module ensures seamless transmission of inspection data to a central monitoring system. This connectivity feature enables real-time data analysis and immediate alerting mechanisms, ensuring that any detected issues can be addressed promptly. Remote monitoring capabilities facilitated by the module's connectivity options mean that operators can constantly watch pipeline health from anywhere, significantly reducing the need for manual inspections and increasing the overall efficiency of pipeline maintenance operations.

The ROCK CM3's powerful processing capabilities and advanced connectivity options provide a solid foundation for developing a smart pipeline inspection system. Such a system could dramatically improve the efficacy and reliability of pipeline inspections, utilizing cutting-edge technology to safeguard critical infrastructure efficiently and effectively.

Potential Impact and Benefits

The advent of smart pipeline inspection systems, such as those leveraging the capabilities of the ROCK CM3 module, presents a paradigm shift in how pipeline integrity and maintenance are approached. These systems offer a range of benefits, from improved safety to cost savings, all while ensuring regulatory compliance and minimising environmental impact.

Improved Safety and Early Issue Detection

One of the primary benefits of smart inspection systems is their enhanced safety. By utilizing technologies like smart pigs, eddy current testing, and magnetic flux leakage, these systems can detect defects, corrosion, and leaks early on. This capability significantly reduces the risk of accidents, spills, and environmental damage, ensuring the well-being of both people and the planet. The predictive nature of these technologies allows for proactive maintenance, addressing potential issues before they escalate into major problems.

Reduced Maintenance Costs and Downtime

Smart pipeline inspection systems can significantly cut down maintenance costs and operational downtime. By enabling in-service inspections, these systems eliminate the need for pipeline shutdowns, which are time-consuming and expensive. The detailed data collected allows for accurate assessments, minimizing the need for repeated inspections or extensive repair work. Moreover, predictive maintenance strategies, facilitated by data from sensors, can forecast future failures, allowing for timely interventions that prevent costly unplanned shutdowns.

Compliance with Regulations and Environmental Protection

Smart inspection systems help ensure compliance with increasingly stringent regulatory requirements, safeguarding against leaks and corrosion that can lead to regulatory penalties. By promptly addressing these issues, companies can avoid legal repercussions and maintain their operating license. Additionally, the systems play a crucial role in environmental protection, detecting leaks early to prevent spills and contamination, thus supporting sustainable operations.

Deploying smart pipeline inspection systems that leverage the power of the ROCK CM3 module offers substantial benefits across various dimensions. These systems enhance safety and efficiency and ensure compliance and environmental stewardship, heralding a new pipeline maintenance and operation era.

Future Directions

The future of smart pipeline inspection technologies is poised for significant advancements, driven by integrating artificial intelligence (AI), satellite monitoring, autonomous vehicles, and enhanced sensor technologies. These innovations promise to revolutionize pipeline integrity management, offering unprecedented safety, efficiency, and environmental protection.

Enhanced AI and Data Analytics

AI's role in pipeline inspection and monitoring is expanding, with applications ranging from leak detection to corrosion monitoring and managing ageing infrastructure. AI models are trained to interpret massive datasets more accurately and efficiently, identifying potential issues before they pose a risk. As computational capabilities grow, these AI systems' precision and predictive power will enable more proactive maintenance strategies and operational optimisations.

Satellite-based Monitoring

Satellite technology, combined with AI, is emerging as a powerful tool for pipeline monitoring, offering a bird's eye view of infrastructure spread over vast and often remote areas. This approach detects third-party interference, vegetation changes, and ground deformations, among other risk factors. The high temporal frequency of satellite imagery and analyses enables daily reports, making it a highly effective monitoring solution.

Autonomous Inspection Vehicles

The development of autonomous robots for subsea pipeline inspection represents a leap forward in ensuring the safety and integrity of underwater infrastructure. These robots, equipped with smart touch sensors, video cameras, and scanning sonars, can autonomously navigate along pipelines, detecting leaks, structural failures, and corrosion with high accuracy. This technology reduces the risk associated with human-operated inspections and significantly cuts costs and environmental impact.

Integration of Additional Sensors

The future will likely see the integration of an even wider array of sensors into smart pipeline inspection systems. These could range from advanced acoustic sensors for detecting minute leaks to chemical sensors capable of identifying specific substances or changes in pipeline material integrity. Integrating such sensors, powered by the ROCK CM3's processing capabilities, would enhance the system's real-time ability to monitor a broader spectrum of potential issues.

The ROCK CM3 module, with its robust processing power, connectivity options, and support for a range of interfaces and software, is well-positioned to be at the heart of these future developments. Its ability to process data from multiple sensors in real-time, support complex AI algorithms, and facilitate autonomous control of inspection vehicles makes it an ideal platform for next-generation smart pipeline inspection technologies.

Conclusion

The ROCK 3 Compute Module is the precipice of transforming pipeline inspection and maintenance. With its potent combination of processing power, connectivity options, and the ability to support advanced data analysis and AI algorithms, it embodies the forefront of technological innovation in infrastructure management. This module's capabilities promise to enhance safety, efficiency, and environmental protection and redefine what's possible in pipeline monitoring and maintenance. As the industry stands on the brink of this digital frontier, there's an open invitation to envision and develop new, groundbreaking applications that leverage the full power and versatility of the ROCK CM3. The journey toward smarter, more resilient infrastructure systems is just beginning, and the ROCK CM3 is poised to lead the way.