Flat Flexible Cable and Flexible Printed Circuit Solutions for Modern Interconnect Design

Flat flexible cables and flexible printed circuit solutions enable high-density, high-speed connections across a wide range of modern electronic applications. While Molex delivers the interconnect technology, Sager supports engineers with design guidance, prototyping, and supply chain execution.

Executive Summary

As electronic devices become smaller, faster, and more functionally dense, interconnect design has become a core engineering priority. Flat Flexible Cables (FFCs) and Flexible Printed Circuits (FPCs) are essential to this shift, enabling compact, high-speed, and mechanically reliable connections across a range of demanding applications.

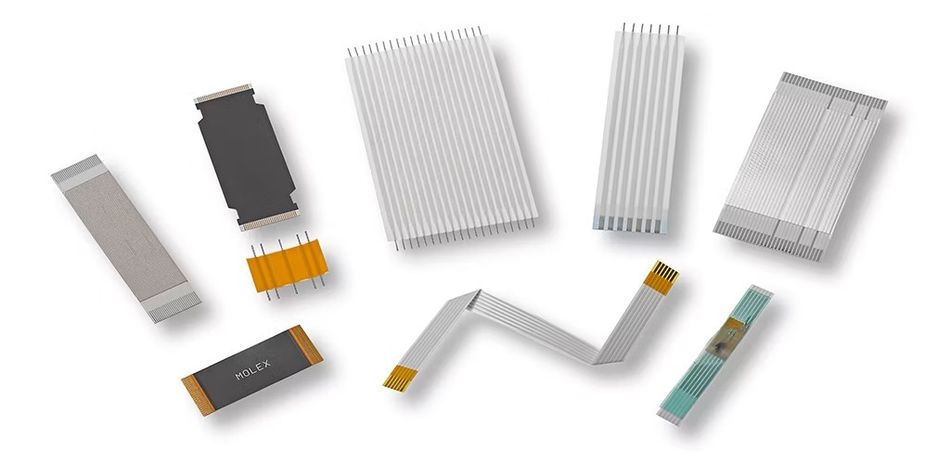

This article introduces Molex’s Premo-Flex portfolio, a comprehensive lineup of standard and customizable FFC/FPC solutions engineered for flex life, signal integrity, and tight space constraints. Supported by Molex’s global manufacturing and simulation capabilities, Premo-Flex helps engineers address both off-the-shelf and purpose-built interconnect challenges.

Complementing this technology, Sager Electronics delivers critical engineering and supply chain support, from early-stage cable selection to fast prototyping and scalable production. Their hands-on collaboration helps engineers identify the right interconnect solution quickly, align with system requirements, and transition smoothly from design to deployment.

Together, Molex and Sager provide complete, engineer-driven interconnect solutions for high-performance systems across medical, datacom, industrial, automotive, aerospace, and other advanced electronics applications.

Introduction

In electronic product development, interconnects are often one of the last components specified, particularly flexible cables, which can appear secondary to connectors or board layouts. However, mismatched or poorly selected cables can compromise signal integrity, mechanical performance, and system reliability under dynamic or space-constrained conditions.

Molex, a global leader in connectivity technology, brings deep engineering expertise to flexible cabling as well. Its Premo-Flex product line includes thousands of standard FFCs and FPCs, designed to meet the diverse requirements of embedded systems.

Where Molex provides breadth and precision in product development, Sager Electronics helps customers bridge the gap between design and execution. Through collaborative consultation, proactive sampling, and long-term inventory planning, Sager enables faster prototyping and smoother transitions to production.

This article presents a structured overview of Premo-Flex solutions and how they fit into the modern engineer’s toolkit. It also introduces Molex’s broader printed circuit solutions and capabilities, including fine-line etching, circuit layering, and rigid-flex integration, which support advanced applications where electrical and mechanical performance is critical.

Molex Premo-Flex Portfolio: Customizable Flat Flex Cable Solutions

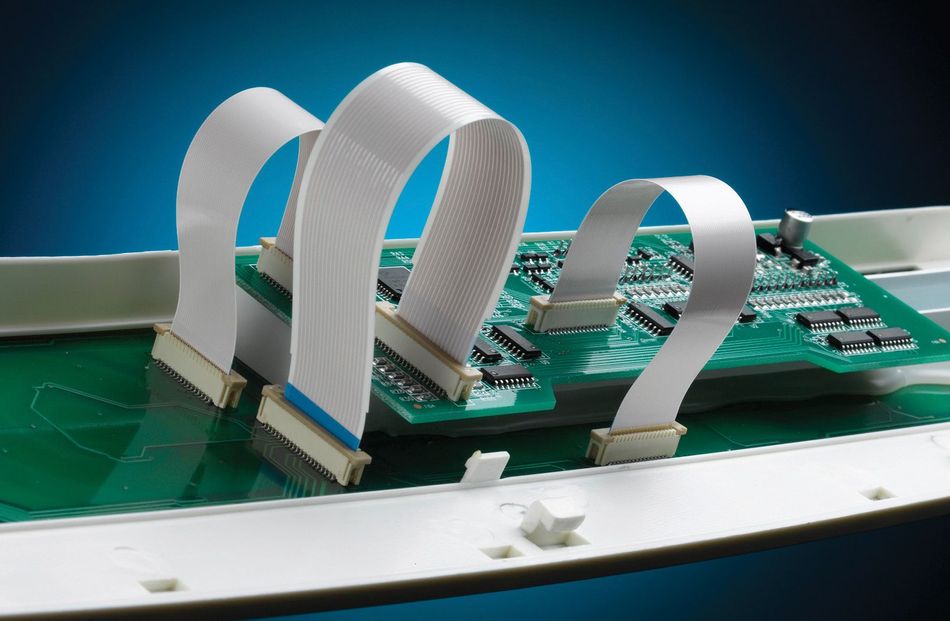

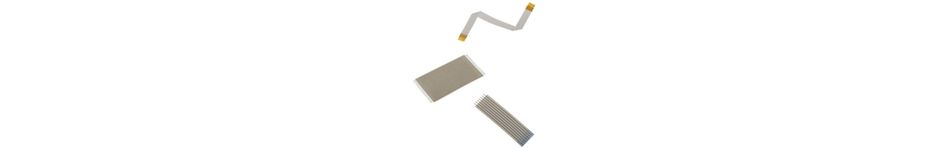

The Premo-Flex family, in Molex’s portfolio of FFCs and FPCs, is designed to meet the performance, space, and integration demands of today’s electronic systems. These cables are used to connect printed circuit boards to one another or to displays, sensors, and user interfaces, providing high-density, low-profile pathways for signal transmission in compact or dynamic environments.

Premo-Flex includes over 18,000 standard part numbers, available in various pitch sizes (from 0.25mm to 1.25mm), flex life ratings (from 10,000 to 2.5 million cycles), and plating options (gold or tin). These standard solutions are further supported by extensive customization capabilities, including custom pitch sizes up to 2.54mm, tailored lengths, termination types, fold configurations, printed identifiers, and grounding options.

Engineers can choose from cables optimized for signal integrity, mechanical flexibility, EMI shielding, high-speed performance, or cost-sensitive direct-to-board implementations, depending on application requirements.

Molex also supports application-specific designs through its global manufacturing infrastructure, capable of producing high-mix, mid-volume runs that are well suited to agile OEM development cycles. For applications requiring higher reliability and tighter signal performance, Molex offers electrical simulation and high-speed performance testing, ensuring each cable design is validated under realistic conditions for impedance, crosstalk, vibration, and thermal performance.

Premo-Flex is designed as a complementary technology to Molex’s connector systems, allowing engineers to specify matched cable–connector pairs for a fully integrated interconnect solution. However, Molex also offers intermateable and hybrid options, enabling compatibility with other connector brands or configurations.

By combining a broad standard offering with advanced customization and validation support, the Premo-Flex portfolio gives engineers the flexibility to meet strict mechanical and electrical requirements, without extended development timelines or complex procurement challenges.

Solutions-Based Product Categories

To simplify cable selection and align with application-specific design needs, Molex categorizes its Premo-Flex portfolio into solution-driven families. Each group addresses a distinct engineering constraint, from mechanical stress to EMI sensitivity, helping designers quickly identify the most suitable option.

Flexibility: Premo-Flex cables are available in three flex life grades - Flexible, Extra-Flexible, and Ultra-Flexible, to support varying motion profiles and mechanical stresses. Flex life ranges from 10,000 to 2.5 million cycles, depending on insulation thickness and conductor configuration. Thinner cables offer greater bend endurance, making them ideal for dynamic applications like printer heads or medical cabinet doors that undergo repetitive movement.

Superior Retention: For high-shock or vibration-prone environments, Molex offers retention-enhanced cables with notched edges or molded ears. These mechanical features improve retention force by up to 5 times compared to straight termination cables, minimizing the risk of intermittent disconnects in automotive, industrial, or mobile applications.

Miniaturization: Devices like wearables, smartphones, and compact medical instruments require ultra-fine interconnects. Premo-Flex miniaturized options are available with staggered or offset pin layouts, enabling high circuit density in limited board space without sacrificing signal quality.

High-Speed: Engineers developing data-intensive systems can rely on Premo-Flex Low-Voltage Differential Signaling (LVDS) cables, which feature controlled impedance of 90 Ω or 100 Ω, suitable for USB 3.0, HDMI, and other high-speed protocols. Depending on length, supported data rates range from 2–5 Gbps (12–24") to 5–10 Gbps (2–10"). These cables are widely used in datacom, infotainment, and embedded display systems.

EMI Shielding: To mitigate noise in electrically dense environments, Premo-Flex includes EMI-shielded cables with aluminum foil wraps and grounded first and last pins. This design helps preserve signal integrity in industrial control units, RF-sensitive modules, and mixed-signal systems.

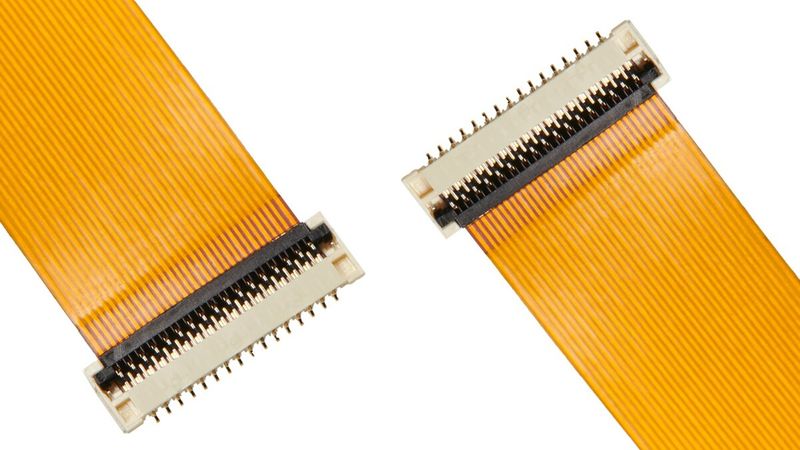

Intermateable: Molex offers off-the-shelf FFCs that are intermateable with Hirose FH28, FH52, and TF31 connectors. These options allow engineers to integrate Premo-Flex into designs that do not use Molex connectors, while still ensuring high retention and mechanical compatibility. For other Non-Molex connectors, Molex can deliver fully customized solutions to ensure optimal performance and compatibility.

Direct-to-Board: For cost-sensitive or space-constrained layouts, Molex provides direct-to-board options that eliminate connector requirements. These include hot bar solder cables and round flat cables (RFCs) for through-hole connections, which are ideal for compact assemblies where both space and BOM cost is limited.

Rigid-Flex Integration: Some applications benefit from co-designing flexible and rigid PCB elements as a single assembly. Molex supports such rigid-flex hybrid architectures, improving system durability, reducing connectors, and simplifying assembly, particularly in aerospace, automotive, and military-grade instrumentation.

Dielectric Stacking: Where isolation and multi-signal routing are critical, Molex can fabricate FPCs with custom dielectric and adhesive layer stacks. These builds allow engineers to meet creepage and clearance requirements, as well as specific voltage isolation levels in high-voltage control or mixed-signal environments.

Table 1: Summary of Premo-Flex solutions-based categories

Category | Pitch Range | Key Features | Use Cases |

Flexible | 0.50–1.25mm | Standard flexibility | General-purpose, consumer devices |

Extra-Flexible | 0.50–1.25mm | Thinner insulation | Robotics, automation |

Ultra-Flexible | 0.50–1.25mm | Max flex endurance | Printers, dynamic medical devices |

Superior Retention | 0.30–1.00mm | Notches or ears for high retention force | Automotive, industrial, mobile systems |

Miniaturization | 0.25–0.30mm | Staggered pins, ultra-compact layout | Wearables, smartphones, medical sensors |

High-Speed (LVDS) | 0.50mm | 90/100 Ω impedance, 5–10 Gbps | Datacom, HDMI, USB 3.0, displays |

EMI Shielded | 0.50mm | Foil wrap, grounded pins | Mixed-signal, RF-sensitive systems |

Intermateable | 0.50mm | Compatible with Hirose FH28/FH52/TF31 | 3rd-party connector ecosystems |

Direct-to-Board | 1.00mm | Hot bar solder or RFC, no connector | Low-cost, tight-space layouts |

Rigid-Flex | Custom | Integrated FPC + rigid PCB assembly | Aerospace, automotive, instrumentation |

Dielectric Stacking | Custom | Layered insulation for voltage isolation | HV control, safety-critical systems |

When Standard Is Not Enough: Premo-Flex Custom Solutions/Purpose-Built Capabilities

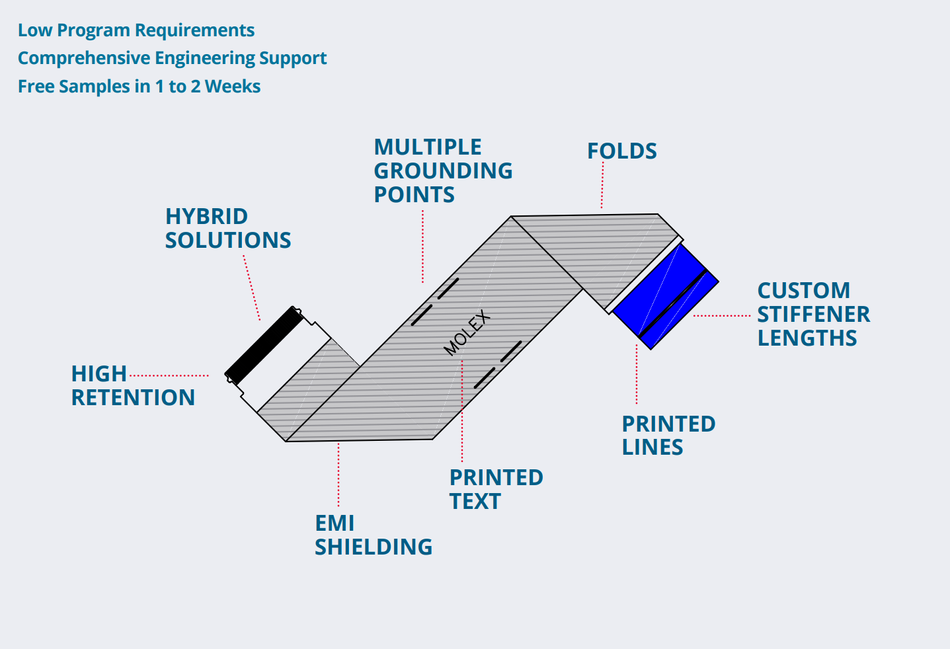

While Molex’s extensive catalog of standard Premo-Flex products covers a wide range of applications, many applications have specific requirements that go beyond off-the-shelf offerings. Molex addresses these needs with customization capabilities that allow flexible interconnects to be tailored precisely to mechanical, electrical, and integration constraints.

Custom builds can incorporate unique pitch sizes, circuit counts, fold configurations, and printed identifiers (text, lines, indicators). For systems requiring EMI control, signal synchronization, or mechanical reinforcement, engineers can specify custom grounding schemes, dielectric layering, or custom stiffeners.

Premo-Flex cables can also be delivered with embedded components such as thermistors, LEDs, ICs, resistors, or transistors, turning the cable into an active or semi-passive element of the system. These componentized builds reduce the need for additional subassemblies, improve compactness, and simplify final assembly steps.

Molex supports custom hybrid terminations as well, for example, combining notched retention features on one end with straight termination or hot-bar solder pads on the other. This enables engineers to match dissimilar connector or board interfaces without introducing additional adapters or intermediate parts.

A signature use case involves folded or pre-creased cables, manufactured to precise mechanical profiles to fit constrained mechanical enclosures. These designs are shipped with folds pre-defined, helping customers eliminate downstream handling steps and assembly variability.

Additionally, Molex can co-design multi-functional interconnects that integrate printed antennas, sensor traces, or power-routing elements, combining signal delivery, sensing, and mechanical connection in one flat cable structure.

All custom projects are supported by Molex’s in-house simulation, high-speed testing, and prototype validation, ensuring electrical and mechanical performance before full-scale production. This level of customization allows OEMs to optimize both function and manufacturability, particularly in mid-volume, performance-critical applications.

Sager’s Role: From Engineering to Execution

While Molex delivers the interconnect technology, Sager Electronics plays a central role in translating design concepts into validated, production-ready solutions. As a technically adept distributor, Sager supports engineers throughout the product life cycle, from specification and prototyping to inventory planning and long-term production support.

Rather than beginning with part numbers, Sager engages engineers at the application level, understanding requirements around flex life, signal speed, EMI exposure, mechanical constraints, and system integration. This ensures each Premo-Flex solution is selected or customized with real-world reliability and manufacturability in mind.

Recognized by Molex as Distributor of the Year in 2024[1], Sager collaborates closely with Molex’s engineering team to refine cable specifications, compare standard and hybrid options, and manage the transition to purpose-built configurations when needed. Their support extends early in the development cycle, helping engineers reduce risk and eliminate costly redesigns.

By combining Molex’s flexible cable technologies with its own design-focused services and digital tools, Sager enables engineers to move confidently from prototype to production with the assurance of technical precision and supply chain continuity.

Application Spotlights

Premo-Flex solutions are used across a broad range of industries where compact form factors, signal reliability, and mechanical resilience are essential. Below are some examples of how engineers integrate Molex’s flexible interconnects into real-world applications, with support from Sager throughout the design-to-production process.

Medical: Medication Dispensing and Cabinet Tracking

In hospitals, Premo-Flex cables are used in automated medication cabinets, where repeated door movements demand long flex life and EMI shielding to maintain data integrity. Molex’s ultra-flexible, foil-shielded FFCs ensure reliability across thousands of open-close cycles, while Sager helps customers fine-tune grounding and retention for high-activity use.

Industrial: Dynamic Robotics and Automation

In robotic arms and automated tools, cables must withstand repeated bending and vibrations. Extra-flexible and ultra-flexible Premo-Flex cables deliver 100K to 2.5M flex cycles, helping manufacturers reduce maintenance intervals and downtime. Sager’s team is well positioned to help customers identify when a custom folded or creased solution is the best solution to integrate into tight mechanical spaces.

Consumer: Wearables and Compact Devices

Smartwatches, earbuds, and handheld gaming devices require miniaturized cables that preserve signal performance in extremely limited space. Molex’s 0.25mm and 0.30mm pitch FFCs with staggered pins offer tight bend radii and clean signal transmission. Sager assists engineers with connector matching and retention features to improve user durability.

Datacom: High-Speed Routing in Routers and Switches

Premo-Flex LVDS cables with controlled impedance (90/100 Ω) are widely used in networking gear where USB 3.0 or HDMI protocols must be supported across small internal distances. Combined with Molex Easy-On connectors, these cables enable reliable high-speed transmission in compact form factors.

Aerospace: Signal Control in Instrumentation

Aerospace-grade designs require highly customized cables with defined folds, EMI shielding, and strict dimensional tolerances. Molex and Sager jointly deliver ultra-flex assemblies with enhanced dielectric isolation and component integration for flight-certified equipment.

Automotive: Battery Management and EV Power Distribution

In electric vehicles, custom FPCs are used for battery monitoring, control, and low-voltage power routing. These interconnects reduce harness complexity, weight, and thermal load while maintaining performance under vibration and temperature extremes.

Why Quality Matters: Molex versus Other Alternatives

In the pursuit of cost optimization, some engineering teams consider low-cost flat flexible cables sourced from generic manufacturers. While such components may meet basic dimensional or electrical specs on paper, they often fall short in flex life, signal integrity, mechanical retention, and quality consistency - especially in applications that involve movement, vibration, or EMI exposure.

Molex distinguishes itself with an emphasis on manufacturing quality, material traceability, and in-house validation. Every Premo-Flex cable is built to consistent mechanical and electrical tolerances, and designs undergo rigorous testing for vibration resistance, dynamic flexing, thermal cycling, and impedance control. This ensures compliance with application requirements with long-term field reliability.

Molex’s value is particularly evident in mid-volume programs where the cost of failures, redesigns, or field recalls far outweighs the marginal savings of using unverified components. Premo-Flex solutions are engineered for consistent performance and dependable integration, which is critical in industrial contexts.

In collaboration with Molex, Sager Electronics adds another layer of confidence by offering design support, proactive inventory planning, and fast access to samples and replacements. Together, they provide a supply chain that is both responsive and technically aligned, minimizing risk across the product development cycle.

By focusing on total cost of ownership, not just unit pricing, engineers can ensure their interconnects contribute to product quality, performance, and long-term success.

Conclusion

In today’s complex electronic systems, choosing the right flexible interconnect is critical to ensuring performance, reliability, and manufacturability. Molex’s Premo-Flex portfolio offers engineers a complete range of standard and customizable flat flexible cables, addressing diverse needs across signal speed, mechanical resilience, EMI shielding, and space constraints.

Through its relationship with Molex, Sager Electronics plays a key role in helping design teams make informed cable selections, accelerate prototyping, and transition smoothly into production. Their combined expertise reduces design risk, shortens development cycles, and delivers a robust supply chain foundation.

To explore flexible cable options, access technical resources, or request samples, visit Molex Premo-Flex Cable Selector Guide on Sager's Website or reach out to the technical team via this short form for application-specific support.

References

[1] West P. Sager Electronics awarded Distributor of the Year by Molex [Internet]. Procurement Pro; 2024 Jul 17. Available from: https://procurementpro.com/sager-electronics-awarded-distributor-of-the-year-by-molex/

[2] Molex. Leading automotive OEM leverages Molex custom engineering to keep project on time and on budget [Internet]. Molex; Available from: https://www.molex.com/content/dam/molex/molex-dot-com/en_us/pdf/application-briefs/987651-8234.pdf

[3] Molex. Tech Guide: Premo-Flex Sample Kit – Flat Flexible Cable [Internet]. Molex; Available from: https://www.molex.com/content/dam/molex/molex-dot-com/en_us/pdf/solutions-guide/987652-1121.pdf