Engineer's Guide to PCB Manufacturing and Intellectual Property

Understanding your rights and responsibilities is essential to securing your innovation. Further, taking advantage of cloud manufacturing can mitigate substantial risk.

Intellectual Property (IP) is a way of describing the ownership of intangible creations or ideas. IP awards exclusive rights to the creators of ideas to safeguard them against use by others, particularly in instances where others could earn a profit. For engineers working on PCB design, understanding how to protect their innovations is essential for guaranteeing appropriate financial and intellectual attribution. This article discusses the foundations of IP protection for PCBAs with detail about the role PCB cloud manufacturing can play in securing IP.

Why PCB Intellectual Property is essential

The theft of all or part of a company's PCB design has consequences beyond just the loss of the effort of innovation. Illegally replicated products may cause substantial financial and reputational damage to a company – even to bankruptcy.

Product teams invest thousands of hours into innovation. Without adequate protection, these efforts can be very quickly stolen and passed off as a competitor's innovation.

Intellectual Property protection of PCBAs requires both formal applications for protection of innovation under local and international laws and processes and adequate security measures of data transfer to ensure the risk of theft is low. While formally protecting your ideas under the law is critical – the risk that data can be stolen and already implemented before the wheels of the legal system engage is high.

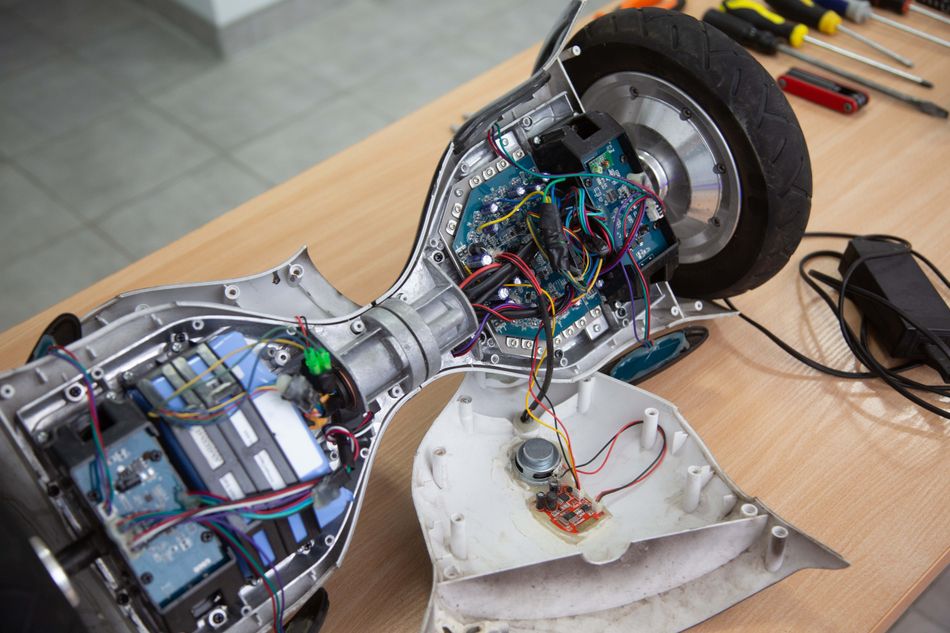

Trying to prove that the effort and innovation were yours, to begin with, may involve complex and expensive legal action that can result in nothing. The classic example is hoverboard inventor Shane Chen; despite a patent, his designs for the wildly popular micro-mobility product were stolen and produced en masse prior to Christmas 2016. Chen made zero profit[1].

Four Types of Intellectual Property

Four core laws relate to protecting your intellectual property. Each protects different aspects of your design and requires different actions to ensure protection. These laws can differ depending on your location, type of company, and where your products are sold or marketed. We strongly recommend you employ a legal advisor with expertise in this domain.

Copyright

Copyright is a form of ownership given to the original innovator to preserve their intellectual property. Under United States Copyright Law (17 U.S.C. §§101 et seq.), all works of authorship are automatically copyrighted when they are "fixed in a tangible medium of expression[2]. However, for full legal protection, it is best to formally register your designs including any associated software. If your product has code engineered into a chip, a specific type of registration called a "Mask Work Registration" protects the artwork for the chip itself[3]. The PCB itself should be registered for copyright along with the schematic and netlist.

Trademark

Trademarks are unique words, phrases, ideas, marks, or designs that make it easy to tell that a product or service belongs to one party and not another. To legally protect trademark items, you will need to register them with the US Patent and Trademark Office, or USPTO for short. You can register your business name, slogan, brand, products, and service name as a trademark. Trademarks do not protect your actual PCBA designs or their schematics, but they can be important to protect your brand identity.

Patents

The concept of a patent is to protect any discoveries or inventions that are regarded to be beneficial in any form. These inventions include new productions, new compositions, methods, etc. Patents plays a significant role in the invention of new products and ideas. If you have designed an entirely new PCBA or mode of design, it may be eligible to be registered with the USPTO[4]. In most cases, a patent will continue for 20 years from the date of filing the patent application. Others are legally prohibited from creating, selling, or utilizing your product or technique during this period.

Trade secrets

For the most part, trade secrets are classified as proprietary knowledge that adds to a company's competitive advantage over its competitors, such as business operations and formulae[5]. If your PCBA design possesses trade secrets, you may begin safeguarding them by obtaining confidentiality agreements from anyone you do commercial discussions with. Clauses may also be included in agreements regarding your product design with associates, consultants, and individual workers, among other parties. Always consult with an expert contract writing attorney to ensure that you include all of the appropriate protective provisions in your contract design.

Where PCB intellectual property risks occur

PCB designs are vulnerable to theft throughout their design lifecycle; vulnerable during the design process as well as during manufacturing – however with the correct security processes and by using trusted manufacturing partners these risks can be reduced to acceptable levels.

Recommended reading: Why Should You Use Rigid-Flex PCB Assembly?

PCB design usually requires a team of experts, including material and electrical engineers, who collaborate to ensure the board has the required functionality, fits well within the product itself, meets the required standards, and is affordable and manufacturable. This requires the movement of various documents and files between team members. The core types of data that will have intellectual property are:

Schematics: Schematic layouts provide information on component classifications, values, and connections.

Netlists: These text files list all of the board's connections and the components utilized in the design, as well as their standard identifiers, quantities, and part numbers.

Component symbols: These files may be standalone or integrated into the design database. Most symbol information is available from component suppliers and other sources and is not required to be protected; however, certain application-specific parts may include private information.

Constraints and information stack-up: This data comprises increased design data, such as the PCB layer configurations that could be utilized in reverse engineering.

To protect the data of your board, it is essential to regulate how the information is disseminated.

Protecting intellectual property during design and manufacturing

All engineering teams working on PCB design must consider how they will protect their data and design from day one. Setting up high-quality data and file management and communication protocols that undergo regular review and testing is the best way for teams to protect their innovations. This also includes that all team members from the engineering staff to admin support are well versed in the risks, standard operating procedures, and the procedures required if a leak, bug, attack, or threat occurs.[6]

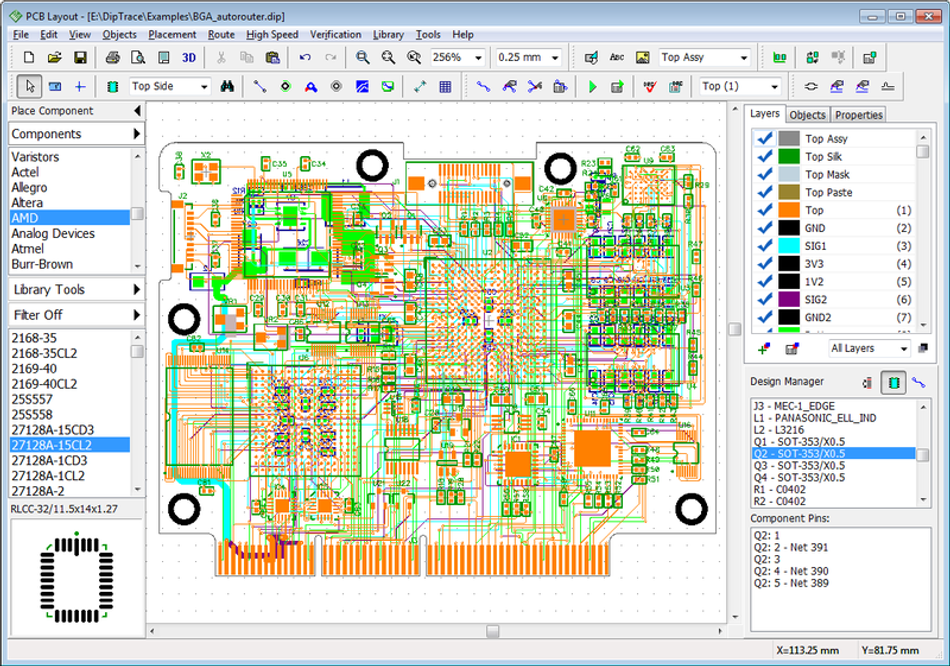

During PCB manufacturing, the risk of theft of innovation shifts from the digital to the physical – with the increased risk of the physical board being stolen and reverse engineered. PCB cloud manufacturing is an emerging method of PCB manufacturing that has security baked into its procurement and manufacturing process enabling design teams of all sizes to confidently get boards produced.

Protecting intellectual property using cloud manufacturing

PCB cloud Manufacturing is an emerging manufacturing paradigm that utilizes the Internet of Things, cloud computing, and other tools to transform manufacturing resources into services. PCB cloud manufacturing offers a way for engineering teams to have far greater control and security over their manufacturing processes by drawing together the diverse aspects of requests-for-quote, material and component sourcing, testing, and manufacturing, into a single streamlined framework.

Cloud manufacturing enables all of the design and manufacturing data of a board to be maintained within a single secure digital platform – protected from beginning to end from outside threats.

PCB cloud manufacturing with MacroFab

To further illustrate the benefits of PCB cloud manufacturing, let's use the example of US-based service provider MacroFab. The company operates a diverse network of PCB manufacturing facilities in the US and Mexico and Canada where IP protection laws are strong, particularly when compared to "traditional" PCBA manufacturing companies such as China. According to the New York Times, China is the largest source of counterfeit and pirated goods – posing a genuine risk to PCB designers.[7]

Every facility in the MacroFab network has been thoroughly vetted to ensure they meet the highest standards of safety and security – this process is guaranteed through an agreement of assurance. This removes the need for engineering teams to do this, scouring and vetting themselves and renegotiating individual manufacturing contracts.

Engineering teams connect directly with the MacroFab through a single secure portal and their expert team does the hard work of routing your order to the most appropriate and available manufacturing facility. There is no need for multiple file sharing across various manufacturing facilities, external testers, or assembly facilities. All the board and product data are kept within a single digital thread that maintains a history of all design iterations which not only provides IP protection but enables design teams to have a 360-degree view into the design development of their products. An asset that is just as valuable and worth protecting as the finished product.

Conclusion

The article has discussed critical aspects of intellectual property in relation to PCB design and manufacture. In summary, all engineering teams must protect their IP via a multi-pronged approach that includes:

- Understanding their legal rights and responsibilities

- E=Ensuring data is protected by integrated security protocols,

- Minimizing theft in manufacturing by taking advantage of secure PCB cloud manufacturing.

About the Sponsor: MacroFab

MacroFab is an electronics manufacturing digital platform that provides production options throughout North America. MacroFab aims to make it faster and easier to bring new electronic products to market through its software-driven approach to electronics manufacturing.

References and further reading:

- The inventor of the hoverboard says he's made no money from it [Internet]. the Guardian. 2022 [cited 26 May 2022]. Available from: https://www.theguardian.com/technology/2016/jan/08/hoverboard-inventor-money-rights-knockoffs

- U.S. Code: Title 17 [Internet]. LII / Legal Information Institute. 2022 [cited 26 May 2022]. Available from: https://www.law.cornell.edu/uscode/text/17

- Husick L. Ask Dr. Copyright . . . Protect Your Software, Circuit Boards, and Mask Works [Internet]. Adam G. Garson, Esq. | Lipton, Weinberger & Husick | Trademark Law & Intellectual Property. 2022 [cited 26 May 2022]. Available from: https://garson-law.com/ask-dr-copyright-protect-your-software-circuit-boards-and-mask-works/

- Patent basics [Internet]. 2022 [cited 26 May 2022]. Available from: https://www.uspto.gov/patents/basics

- Trade secrets [Internet]. Wipo.int. 2022 [cited 26 May 2022]. Available from: https://www.wipo.int/tradesecrets/en/

- Knechtel J. Protect Your Chip Design Intellectual Property. Proceedings of the International Conference on Omni-Layer Intelligent Systems. 2019.

- https://www.nytimes.com/2022/04/27/business/economy/china-trade-intellectual-property.html