Carbon Fiber 3d Printing: How to 3D Print Strong Parts

A carbon fiber 3D printer allows you to produce strong, light weight parts. With the right printer and matching carbon fiber filaments, you can get started in an instant. In this article you will find everything you need to know about carbon fiber 3D printing!

Carbon fiber 3D printing offers exceptional dimensional stability in strong, stiff parts with a fine surface finish and high heat resistance - ideal for functional, performance applications.

This article was first published on

bigrep.comWhat is Carbon Fiber Reinforced Plastic (CFRP)?

Carbon fiber reinforced plastic (CFRP) is, as its name suggests, a plastic material reinforced with carbon fiber. These composite materials bring together the qualities and performance properties of carbon fiber with the polymer material it is reinforcing. That is, the printability and ease-of-use of a standard thermoplastic like PLA, ABS, or PET gains superior performance properties from including chopped or continuous carbon fiber content.

The carbon fibers usually come in one of two forms:

- Long woven fibers

- Chopped carbon fibers

Long woven fibers are come in mats that are very similar to fabric. For fabrication these fabrics are laid in a mold and then impregnated with a plastic epoxy. Then they have to be cured and hardened in a heated environment. This process is very time consuming and mostly used in manual processes.

Chopped fibers are mostly used for industrial production and also 3d printing. These carbon fibers come as a "filler" material in thermoplastic materials for injection molding or as carbon fiber filaments to use in 3D printers. They can be processed like any other thermoplastic material. But they have some extra requirements to your equipment, which we will see later.

What is Carbon Fiber Filament?

Carbon fiber filament is simply 3D printer filament made using CFRP.

BigRep's PET-CF Filament is an excellent example of this type of material. Made of PET (polyethylene terephthalate) reinforced with carbon fiber, PET-CF offers dimensional stability and low moisture absorption that can be 3D printed to produce exceptionally strong, stiff parts with a fine surface finish and heat resistance up to 100°C.

FFF (extrusion-based) 3D printing uses chopped carbon fibers. These small — sub-millimeter-long — fibers are mixed into a standard thermoplastic as a reinforcing material. Continuous fiber strands are stronger and longer, but require a more involved 3D printing process with two print nozzles.

Why you need Carbon Fiber 3D Printing

Industrial environments often demand specific mechanical properties and finely tuned precision. Fortunately, carbon fiber 3D printing brings the strength and stiffness of engineering-grade material to additive manufacturing.

Bringing together the capabilities of a high-strength material and the many advantages of additive manufacturing, carbon fiber 3D printing offers exceptional dimensional stability in strong, stiff parts with a fine surface finish and high heat resistance - ideal for functional, performance applications.

With 3D printing moving ever deeper into end-use production, the ability to manufacture both parts and tooling using carbon fiber filament is coming ever more into demand.

Pros of Carbon Fiber 3D Printing

The advantages of carbon fiber 3D printing come down to possible the performance properties. These include:

HIGH STRENGTH

- Perhaps the most-touted property of carbon fiber 3D printer filament, high strength is key to its performance — and desirability as a 3D printing material. Carbon fiber offers a strength-to-weight ratio that enables high performance with low density

LIGHT WEIGHT

- Hand-in-hand with its strength is the light weight of a carbon fiber 3D printer filament. Lightweighting is a key advantage of 3D printing in general, and using carbon fiber materials enables that weight reduction without a loss of performance-grade strength.

HIGH HEAT RESISTANCE

- Compared to standard 3D printing materials like PLA, ABS, and PETG, carbon fiber can withstand significantly higher temperatures. Carbon fiber composite materials — using a carbon fiber-reinforced polymer — enhances the heat resistance of the base material for better performance.

STIFFNESS

- 3D printed carbon fiber parts maintain their shape under high stress. In contrast with other materials that trade off strength and durability for stiffness, the rigidity possible with carbon fiber ensures structural integrity.

“BigRep HI-TEMP CF is the best material I’ve ever used. And no warping!” René Helmreich, RH Engineering

Benefits of Carbon Fiber 3D Printing

No material ticks every box. The downsides of carbon fiber 3D printing materials generally include investment, equipment, and brittleness, as well as the makeup of a given material option.

COST

- As an engineering-grade material, carbon fiber 3D printer filament is a premium product. That is, it is inherently more expensive to obtain and use than standard 3D printing materials. Significant engineering goes into the production of every spool of carbon fiber 3D printer filament, and this is reflected in the pricing structure of these materials.

SPECIALIZED EQUIPMENT

- 3D printing with carbon fiber requires specific hardware to appropriately handle these materials. For example, hardened steel nozzles — like the BigRep STUDIO G2's — rather than standard brass or aluminum nozzles must be used to stand up to abrasive carbon fiber filament as they will not erode. High heat is also required to 3D print carbon fiber with full layer bond strength.

BRITTLENESS

- While carbon fiber 3D printer filaments offer high stiffness, the tradeoff there is relatively low impact resistance. High impact force applications may lead to the 3D printed carbon fiber part shattering.

MATERIAL MAKEUP

- Not all carbon fiber 3D printer filaments are made equal. Significant research must be done to ensure full understanding of the difference between filament using chopped versus continuous carbon fiber, for example. While this is not necessarily a disadvantage specific to only this material type, the relative scarcity of options when it comes to carbon fiber 3D printing means that more due diligence must be done when shopping for the best-fit material by composite makeup.

Where is CFRP used?

CFRP 3D printing is best put to use in manufacturing environments. Among the primary uses of these materials are the creation of moulds, jigs and fixtures, and tooling.

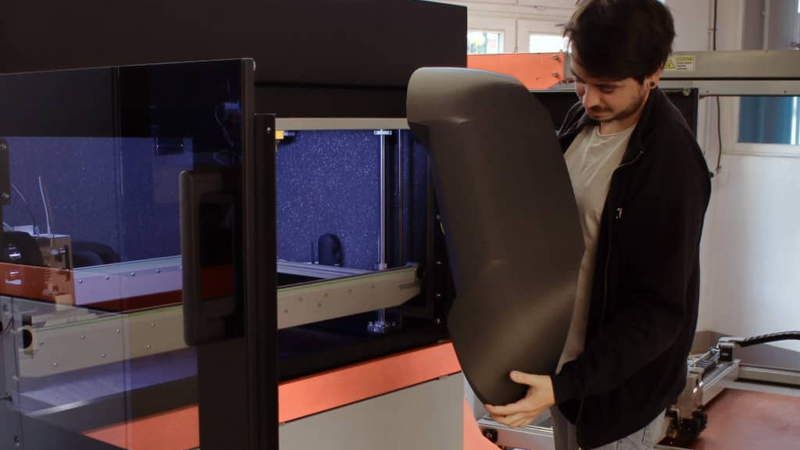

Composite Moulds & Thermoforming Moulds

3D printing moulds is one of the most cohesive ways of advanced and traditional manufacturing technologies working together in an industrial environment. 3D printed moulds offer the complexities and speed-of-production of 3D printing to the mass production capabilities of mould-based manufacturing.

When it comes to composite moulds and thermoforming moulds, the performance properties of CFRP are a natural fit.

Composite moulds are one of the most common manufacturing methods to cost-effectively produce large batches of identical parts. As their name implies, composite moulds are made using composite materials, which can be made in complex shapes and stand up to repeated use — all at a significantly lower cost than aluminum or steel moulds.

Thermoforming moulds are used to use heat and pressure to shape a flat thermoplastic sheet into the mould’s form using conduction, convection, or radiant heating to warm the sheet prior to conforming it to the mould’s surface. Thermoforming moulds must stand up to repeated high-heat usage, requiring specific performance capabilities that can be well delivered via CFRP materials.

Jigs & Fixtures, Tooling

Often viewed as supplemental to manufacturing processes — but vital in their own right — are jigs, fixtures, and tooling. Jigs and fixtures are used to hold specific parts in place throughout different stages of their manufacturing, and tooling is used throughout.

These all-important tools often perform best when customized to the application at hand and may be worn out through highly repetitive use. For these reasons, jigs, fixtures, and tooling are increasingly often 3D printed at the point of use. They can be custom-fit to their specific need and reproduced on demand without outsourcing or waiting on a restock.

3D printed jigs and fixtures and tooling last longer and perform better — especially in terms of long-lasting durability — when made of reinforced materials like CFRP.

Conclusion

When you decide to take on carbon fiber 3D printing, you’re committing to an endeavor that requires significant attention to parameters and specialized equipment and requirements. When those conditions are fulfilled, you can produce best-in-class lightweight, durable, functional parts that can stand up to a variety of industrial uses with all the complexity in design that 3D printing has to offer.