6 Connector Solutions for Servo Motors in Factory Automation Settings

Article #6 Robot Control Series. Motors are becoming increasingly compact but are housing an ever-greater range of functions.

This is the sixth article in a 7-part series examining solutions for robot control. The series looks into solutions for power, data, and signal, necessary to push the role and capabilities of industrial robots. This series is sponsored by Mouser Electronics, an online distributor of electronic components. Through their sponsorship, Mouser Electronics is dedicated to sharing knowledge about the possibility of a greener, more reliable, and better-connected manufacturing future.

The demand for ecological, efficient, and flexible production systems in a globalized and industrialized world is also advancing the development of servo motors and servo drives. The automotive, packaging, and textile industries are just some of the areas where automated production plants controlled by servo technology are boosting productivity and cost-efficiency. Further advances are only achieved through even faster and more precise feedback and control processes—made possible through the interaction of servo motors and servo drives.

Motors today are becoming increasingly compact but are housing an ever-greater range of functions. Given the increased volume of data involved in communication with the drive, it is essential to have reliable connections that operate at the highest possible speeds. What’s more, the numerous internal data and power interfaces need to be connected quickly, reliably, and efficiently. Protection from electromagnetic interference (EMI) through proper shielding and high shock and high vibration capabilities are critical to success.

In this article, we look at six lines of connectors from TE Connectivity created for use in servo motors and drives.

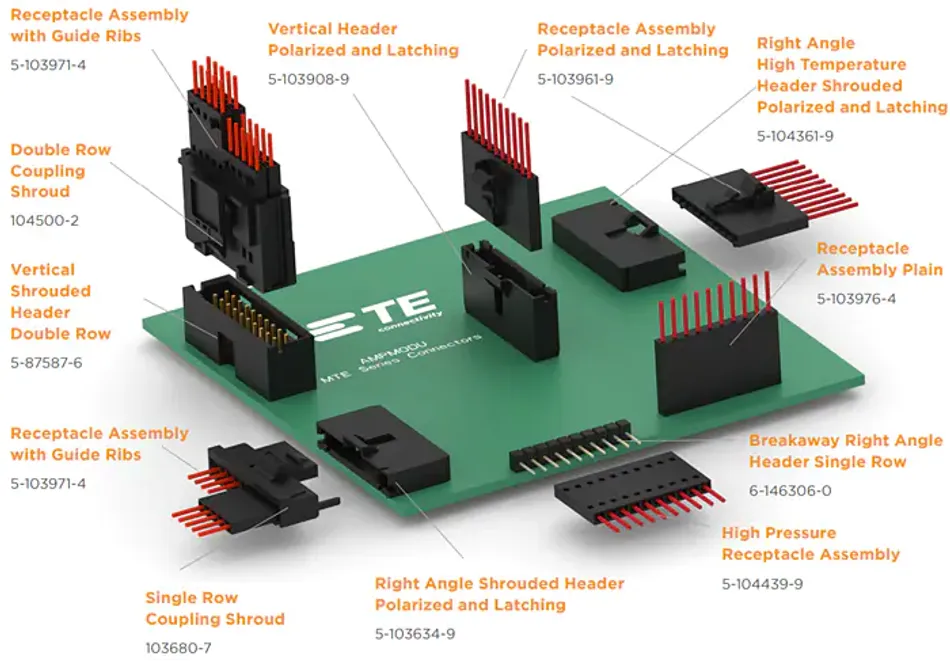

AMPMODU Connectors

The AMPMODU interconnect system is TE’s solution for Automation & Control applications. It includes board-to-board, wire-to-board, and wire-to-wire connectors. The AMPMODU interconnect system contains a large variety of components and can be used in many different industrial applications and systems.

Benefits:

Unique modular concept, utilizing precision formed receptacle contacts and mating posts.

Different configuration possibilities offer design flexibility.

Compact design allows for space-saving.

D-Subminiature Connectors

TE Connectivity provides a complete range of D-Sub connectors. Their full line of D-Subminiature connectors ranges from Right Angle, and Vertical Posted connectors and Cable connectors to the AMPLIMITE .050 Series D-Sub connectors.

Benefits:

Cable and PCB mounted D-Sub connectors.

PCB mounted D-Subminiature connectors available in either right-angle or straight configurations.

Stacked headers reduce overall total header volume by 48 % and PC board area by 38%.

Industrial Mini I/O Connectors

TE’s Industrial Mini I/O Field Installable connector provides wire-termination while also serving as an I/O solution for industrial environments. TE’s Industrial Mini I/O connector is one quarter the size of the conventional RJ45 plug and provides space-saving and the flexibility to use limited space on the PCB more effectively. Designed with two points of contact, this connector is intended for stringent demands of an industrial and high vibration environment. With its piercing termination, the Mini I/O Field Installable version decreases the time usually needed to terminate the wires through soldering and, with a hand tool, field assembly in virtually any environment is now possible.

Benefits:

Less downtime and reliable connections due to higher vibration resistance

Space-saving of up to 75% and increased design flexibility

Field-installable solution

Intercontec Connectors

TE Connectivity's Intercontec Connectors consist of only a few single parts with a modular architecture that makes them highly compatible and usable in many different combinations. The connector assembly is possible without any tools due to the crown clamp that allows the shielding mesh to remain uncut. Multiple codings prevent faulty mating of connectors when wiring complex equipment.

Benefits:

Consists of only a few single parts with a modular architecture that makes them highly compatible and usable in many different combinations

Connector assembly made possible without any tools due to crown clamp that allows shielding mesh to remain uncut

Multiple codings prevent faulty mating of connectors when wiring complex equipment

Follows sophisticated engineering principles safeguarding an easy and efficient assembly process

Dynamic Series Ruggedized Connectors

TE Connectivity's Dynamic Series is a broad product family that provides connector solutions ranging from signal level circuitry through power circuit connectivity in a ruggedized, industrialized package. The connector family is designed for use in control systems applications and is suitable for a wide range of applications requiring high density, signal, and power applications.

The Dynamic Series consists of wire-to-board, wire-to-panel and wire-to-wire connectors with diverse housings available to meet most applications. Standard crimp and spring clamp variations of parts are available. The standardized contacts limit the amount of application tooling required.

Benefits:

Provides connector solutions ranging from signal level circuitry through power circuit connectivity in a ruggedized, industrialized package

Consists of wire-to-board, wire-to-panel, and wire-to-wire connectors with diverse housings

Suitable for a broad range of applications requiring low level signal through high current power circuits

Covers applications up to 65A with variety of sub-categories

Centralized wiring system saves time and money by offering a modular capability to expand as needed.

Standardized contacts limit the amount of application tooling required

Standard crimp and spring clamp variations of parts are available

Figure 2: TE AMPMODU MTE Connectors

Figure 2: TE AMPMODU MTE Connectors

Motorman Hybrid Connector

The fully-configurable Motorman connectivity solution integrates communication, signals, and power for real-time control at higher performance and half the size of current standards. The design and compact size of the Motorman hybrid connector allow for significant space savings in comparison with rectangular industrial connectors. It also reduces the amount of overall cabling needed as well as shortening cable length.

Benefits:

Spacious side access to the inside assists easy and safe configuration

Robust contact system to help minimize effects of impact and vibration

Integration of power, signals, and communication in compact design offers considerable space saving

Contacts may be mounted selectively allowing for design flexibility

This article was initially published by Mouser and TE in an e-magazine. It has been substantially edited by the Wevolver team and robotics writer Dillon Garrison. It's the sixth article of a 7-part series exploring solutions for robot control. Future articles provide an overview of servo motor connections, discuss the role of digital twins in robot connectivity and look at trends in manufacturing automation.

Article one looked at gains made by improved connectivity in industrial settings.

Article two looked at the quality of connectors for harsh environments.

Article three provided an overview of common motor types.

Article four listed 6 Connectivity Solutions For Industrial Robotic Applications.

Article five explores cobots and connectivity.

Article six examined 6 key connectors for automation.

About the sponsor: Mouser Electronics

Mouser Electronics is a worldwide leading authorized distributor of semiconductors and electronic components for over 1,100 manufacturer brands. They specialize in the rapid introduction of new products and technologies for design engineers and buyers. Their extensive product offering includes semiconductors, interconnects, passives, and electromechanical components.