How rechargable disposable thin printed batteries can be produced and used to reliability power IoT products?

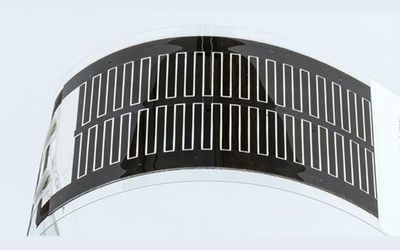

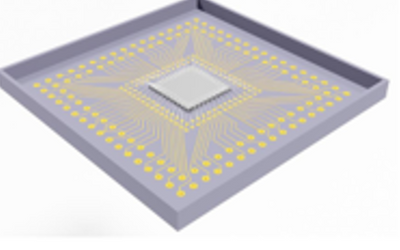

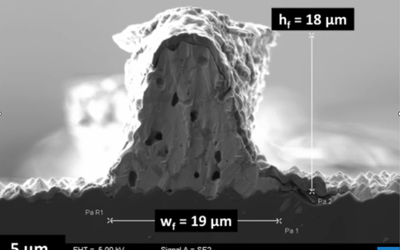

This article describes the TAeTTOOz printable battery technology developed by Evonik and acquired by InnovationLab for upscaling and mass production. In this article, you can learn about the operating principles, the key working characteristics, the material set, production techniques, and emerging applications of this technology