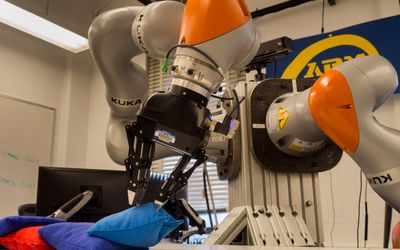

Bionic Handling Assistant

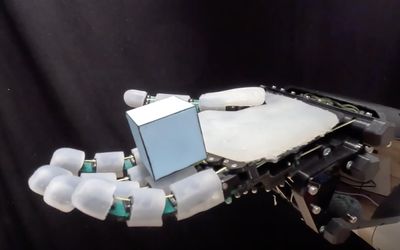

A flexible gripper arm which is modelled on an elephant’s trunk in terms of structure and overall function. The Bionic Handling Assistant is a development platform combining a wide range of technologies and components – from manufacturing concepts to series products like sensors and valves, actuators and grippers, to control technology and software for developing applications and products.

Overview

The Bionic Handling Assistant is a development platform combining a wide range of technologies and components – from manufacturing concepts to series products like sensors and valves, actuators and grippers, to control technology and software for developing applications and products.

The Bionic Handling Assistant works in an easy, freely moving and flexible way. It is even safe if there is direct contact between man and machine. In the event of a collision, the bellows structure gives way immediately and, as a result, does not have to be carefully protected from humans as conventional industrial robots have to be.

References

Describes the background information of the project which includes the components that have been used, the production method (Selective Laser Sintering) and future concepts.