Why IGBTs Remain Relevant in the Era of SiC and GaN Power Devices?

Conventional power electronic devices continue to evolve and remain widely used despite the rise of wide-bandgap technologies. Their strong cost-performance, supply, and proven reliability make them practical choices for applications where miniaturization or weight reduction dont add much value.

Image generated using Google Gemini 3 Pro

Silicon Carbide (SiC) and Gallium Nitride (GaN) power devices now offer strong performance for high-efficiency, high-temperature, and compact applications, and the development of materials such as gallium oxide (Ga₂O₃) and diamond is progressing as well. Even with these advances, many systems continue to rely on silicon power technologies, particularly Insulated Gate Bipolar Transistors (IGBTs).

This article explains why IGBTs remain widely adopted. It covers cost and supply considerations, the value of long-established reliability data, and the types of applications where wide-bandgap benefits offer limited system-level benefits. It also outlines the ongoing improvements that are extending IGBT performance.

High price-performance ratio and supply stability are valued

Currently, the level of attention on power devices is at an all-time high. The primary reason is likely the emergence of next-generation power devices like SiC and GaN power devices. Furthermore, research and development on subsequent-generation power devices such as Ga₂O₃ and diamond power devices is advancing, and the growing anticipation surrounding their practical application is another factor driving this heightened interest.

However, the market introduction of next-generation and next-next-generation power devices does not mean electronic equipment design engineers will universally adopt them. They will simply make a rational choice of the power device that maximizes the value of the target application. If they determine that using existing Silicon (Si) power devices maximizes application value, they will continue using Si power Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs) and IGBTs.

In fact, there are quite a few applications where this judgment leads to the continued use of IGBTs. According to ROHM, a global semiconductor giant, "Interest in IGBTs is rapidly increasing not only in Japan but also overseas." This surge stems from growing demand for IGBTs since around 2021 in industrial equipment, motor drive systems, electric vehicles (EVs), hybrid vehicles (HEVs), and solar power inverters. ROHM reports increased inquiries from manufacturers targeting these applications, with sales volumes steadily rising.

Semiconductor analyst Satoshi Oyama of Grossberg shares this view. He states, "While the SiC power MOSFET and GaN High Electron Mobility Transistor (HEMT) markets will expand going forward, the IGBT market size will not shrink. The IGBT market is expected to maintain relatively high growth, with a compound annual growth rate (CAGR) of approximately 10% even after 2025."

The optimal power device isn't determined solely by superior electrical characteristics

So, which characteristics of IGBTs do electronic design engineers value most when deciding to incorporate them into their applications?

Regarding electrical characteristics, rival SiC power MOSFETs and GaN HEMTs outperform IGBTs in many aspects (Table 1 and Table 2). Specifically, these include lower conduction losses and switching losses, the ability to operate at high speeds (enabling higher switching frequencies), and the capability to operate at high temperatures.

Therefore, incorporating them into an application offers benefits such as extended battery runtime, reduced battery capacity requirements, smaller and lighter power circuits, and lower heat generation. These advantages are particularly valuable in mobility applications. Consequently, SiC power MOSFETs and GaN HEMTs are increasingly being adopted, primarily in applications like traction inverters and DC-DC converters for EVs.

Table 1: On-resistance per area trend

Voltage Rating Range | Si MOSFET | SiC MOSFET | IGBT |

Low Voltage (<200V) | 🔴 Lowest | 🟡Slightly higher | 🟢 High |

Medium Voltage Rating (600–1200V) | 🟠 Increasing | 🔴 Lowest | 🟡 Fair |

High voltage resistance (>3kV) | 🔴 Not possible (Large area, impractical) | 🟠Technically feasible, but RDS(on) increases | 🟢 Lowest |

Low voltage: Si MOSFET is optimal. High speed and low loss.

Medium voltage: SiC MOSFET is optimal. Low loss even at high frequencies, good area efficiency.

High voltage rating: IGBTs are advantageous. Lower on-resistance than SiC and higher chip area efficiency.

Table 2: Performance Comparison of IGBT and SiC Power MOSFET

Parameter | IGBT | SiC Power MOSFET |

Adoption Status | Used in traction inverters for industrial equipment and HEVs | Used in traction inverters for EVs and certain industrial equipment requiring high efficiency |

Voltage Rating Range | Medium to high voltage (600V to 6.5kV) | Medium voltage rating (600V to 3.3kV) |

Switching Frequency | Low to medium frequency (several Hz to 20kHz) | Medium to high frequency (10k to 50kHz, 50kHz and above also possible) |

Conduction Loss | Lowest in the high voltage range of 1200V and above | Lowest (in the voltage rating range of 1200V and below) |

Switching Loss | Medium to high (Usually within an acceptable range due to low switching frequencies) | Lower (losses remain low even at high switching frequencies) |

Reliability and track record | Long-term track record in automotive and industrial equipment | Relatively new technology with limited long-term reliability data |

Cost | Low | Expensive |

Design Difficulty | Numerous existing design examples available; simple gate drive | Requires a design optimized for high switching frequencies (adjustment of gate drive circuits and protection circuits is essential) |

Optimal Applications | Industrial inverters, HEV traction inverters, high-voltage DC-DC converters, UPS | EV traction inverters, medium-voltage DC-DC converters requiring high efficiency |

However, viewed from another angle, applications where these benefits are difficult to realize have no compelling reason to adopt SiC power MOSFETs or GaN HEMTs. Specifically, these are applications where miniaturization and weight reduction are not critical priorities.

Representative examples include industrial equipment and motor drive systems. For these applications, achieving miniaturization and weight reduction through SiC power MOSFETs or GaN HEMTs does not translate into significant added value that substantially impacts sales. Therefore, it is common for designers not to justify the cost increase associated with adopting SiC power MOSFETs or GaN HEMTs. In other words, electronic equipment design engineers are choosing IGBTs based on their high price-to-performance ratio (cost performance).

Beyond this, there are "reasons for adopting IGBTs" that cannot be defined solely by electrical performance. For example, IGBTs offer significantly higher supply stability compared to SiC power MOSFETs or GaN HEMTs. Additionally, with approximately 40 years since their practical implementation, IGBTs have extensive reliability data and a wealth of accumulated know-how regarding their usage.

In practice, electronic equipment design engineers evaluate and select power devices not solely based on electrical characteristics, but comprehensively considering these factors as well. Consequently, even as new power devices emerge, IGBTs continue to be adopted in certain applications.

IGBTs are still evolving

Moreover, the IGBT is by no means a power device of the past. It is still evolving. In other words, there is significant room for further performance improvement.

IGBT performance has improved through a series of device and process-level improvements. Examples include adopting new device structures like "non-punch-through" and "field-stop," thinning Si wafers, and miniaturizing (narrowing the pitch of) trench gates. As a result, they have achieved reductions in collector-emitter saturation voltage (VCE(Sat)), increased current handling capability, improved switching frequency (reducing switching losses), and increased short-circuit withstand capability.

However, there is still room for improvement in thinning silicon wafers and narrowing the pitch of trench gates. Furthermore, according to Mr. Yuji Ishimatsu, Development Manager at ROHM, "There is still potential to enhance IGBT performance. For products launched after 2026, the device structure itself is likely to undergo a significant transformation. We will progressively incorporate these technological developments into our products."

Moving forward, it is highly probable that IGBT products will be introduced to the market that maintain advantages such as "relatively low cost," "high reliability," and "high usability" while offering improved performance.

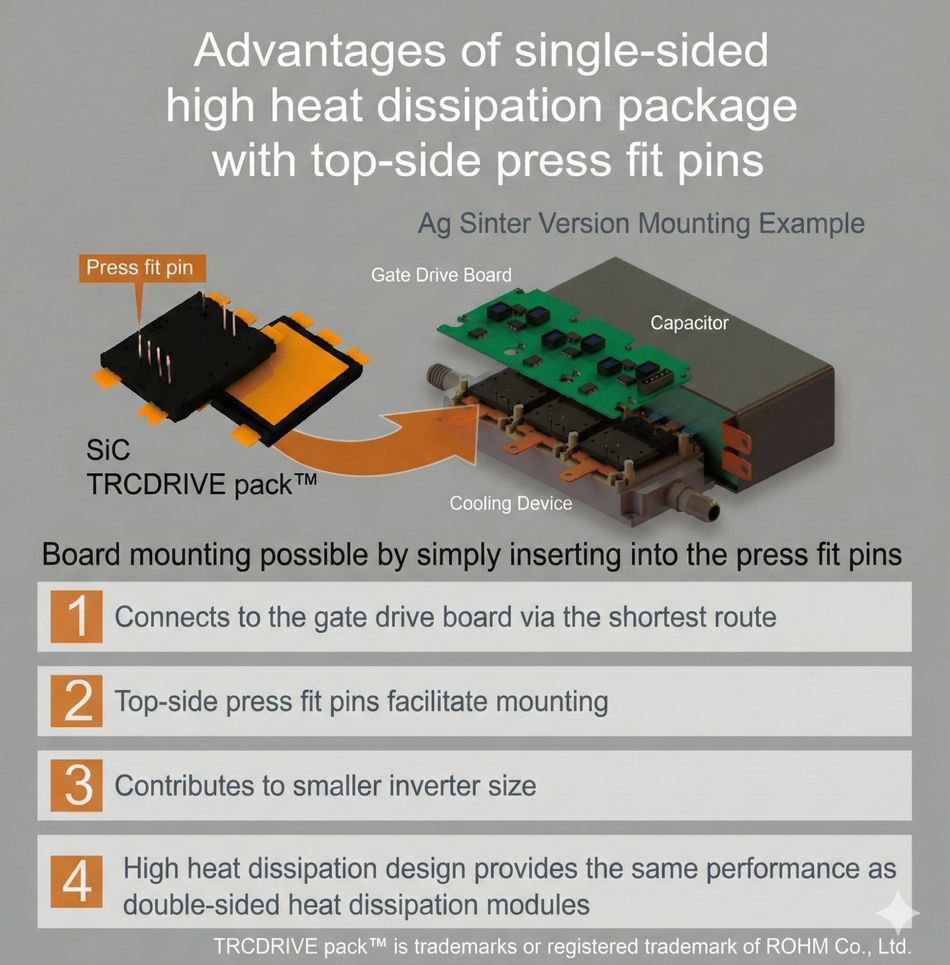

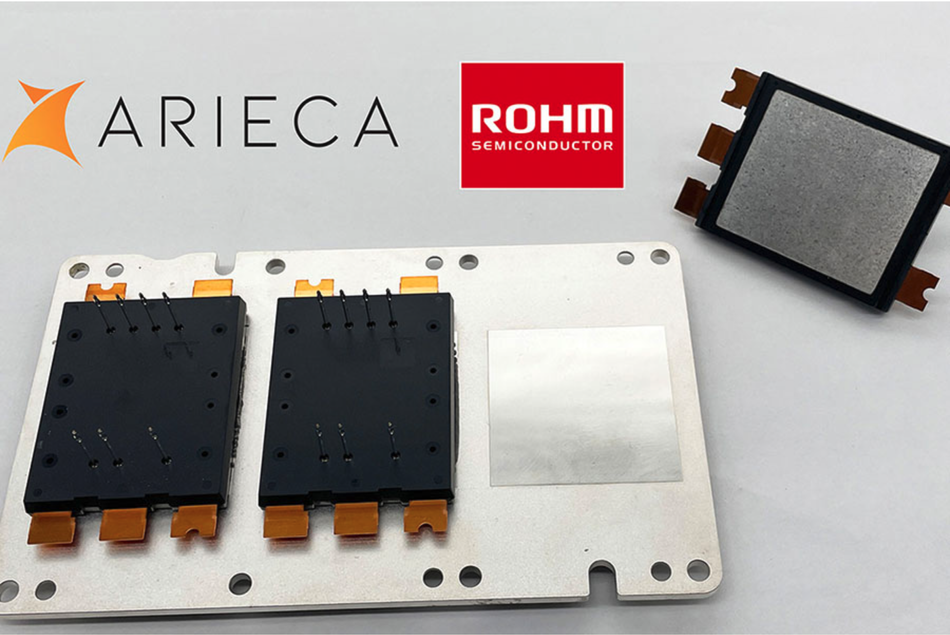

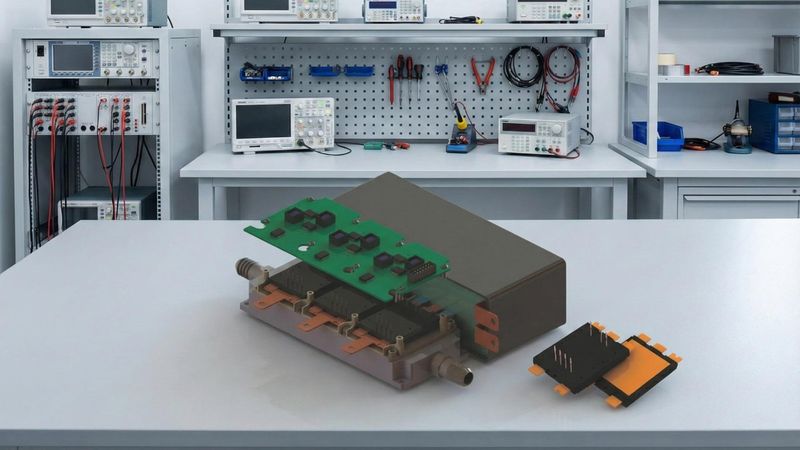

Further technological advancements are also anticipated for power modules incorporating multiple IGBTs. Currently, ROHM has commercialized the TRCDRIVE packTM, a power module featuring high current density and excellent heat dissipation characteristics (Figure 1). The power devices currently employed are the company's fourth-generation SiC power MOSFETs.

This power module features two major characteristics. First, its optimized internal layout minimizes inductance, reducing switching losses. Second, it achieves thermal performance equivalent to competing products despite its compact size, using single-sided heat dissipation.

The implementation methods are as follows: The interface between the chip (power device) and the lead frame inside the module employs silver (Ag) sintering technology, which bonds at high temperature and pressure. This enhances both the reliability of the bond and the power density.

ROHM intends to apply this technology to IGBTs in the near future

In addition, at the interface between the module and the external heat sink, a low-temperature bonding technology using Liquid Metal Embedded Elastomer (LMEE), jointly developed with Arieca Corporation, was established. This technology achieves thermal resistance comparable to Ag sintering bonding, but at lower temperatures and pressures. Consequently, it enhances heat dissipation efficiency while maximizing the module's electrical performance.

A Stable Option in Evolving Power Electronics

Wide-bandgap devices are expanding the options available to power designers, but IGBTs continue to offer a reliable and cost-efficient choice in many systems. Their mature supply chain, established reliability, and ongoing technical improvements ensure they remain a practical solution where the advantages of SiC or GaN provide limited added value.