What Is Cloud Manufacturing? And Who Can Benefit From It?

Cloud manufacturing may not be a familiar term to everyone. But there are good reasons to get acquainted with it.

Michael Mandel’s Forbes article about manufacturing platforms brings out many perks of having manufacturing on the cloud. He sees it as the next step in the manufacturing industry.

How does it actually help the users and why is it considered the future of the manufacturing sector? Let’s see.

What Is Cloud Manufacturing?

If the term “cloud” gives you a headache, let’s try to define that.

The definition of “cloud computing” is the practice of using a network of remote servers hosted on the Internet to store, manage, and process data, rather than a local server or a personal computer.

The same principles of shared information are at use with cloud manufacturing. It is a service-oriented business model to share manufacturing capabilities and resources on a cloud platform.

In simple terms it means that people can visit a website to order their manufacturing, while the production is not limited to one company only. All the necessary info about manufacturers is available on the cloud.

This creates a model where several companies are sharing their capabilities with those website visitors.

At the same time, these platforms are not just mediation services. They offer possibilities to reduce environmental impacts and cut down costs by making intelligent decisions.

Today, we see such manufacturing platforms offering services for sheet metal fabrication, 3D printing, CNC machining, etc.

The Objectives

The main reason for the growing popularity and belief in cloud manufacturing is its sustainability.

Whereas the demands for lower environmental impacts and costs are growing, many are seeking for solutions in the realm of on-demand manufacturing. And cloud manufacturing’s aims align well with those needs:

- Enhanced efficiency

- Reduced production costs

- Optimal resource allocation

Features and Benefits of Cloud Manufacturing

How are these goals attained, though? For that, we shall take a closer look at the key characteristics of cloud manufacturing.

Flexibility

Depending on the manufacturing platform, cloud manufacturing offers a large variety of capabilities at one place.

The manufacturing of parts is assigned to the nearest manufacturer who has the expertise to execute the job. Thus, the supply chains are highly configurable and not fixed, minimising the reliance on certain connections and partnerships.

Also, the automated system’s capability of choosing a production partner based on those qualities accounts for achieving lower costs and lessened environmental impacts through shorter delivery distances.

Production Quality

Quality is one of the key aspects customers look for in manufacturing. Finding great suppliers is not always an easy task though.

Some cloud manufacturing platforms just try to get as many partners on board as possible. Others do their due diligence and send in a bunch of test orders first.

This helps to ensure great production quality without having to go through the pre-vetting process on your own.

Shared Accounts

The access to procurement information is available for anyone involved. While legacy workflows include back-and-forth emailing, the information is not readily available for every related person to see.

With manufacturing platforms, any involved party has an overview of progress. This lets a team of several members work on a project at once without the need for constantly keeping each other updated.

Instant Quotes

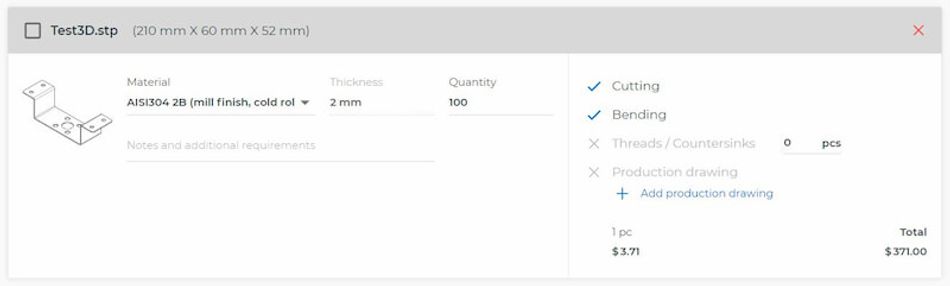

The ability to receive instant quotes for CAD models or drawings enhances efficiency and offers optimal resource allocation. Less time is now spent on communication and engineers can direct their efforts towards value-adding activities.

All the while these intelligent systems are accruing data to optimise the pricing process further.

Manufacturability

Giving out instant quotes needs a complicated system able to assess the uploaded files. This also means that the platform should not give out quotes to parts that are impossible to manufacture.

Assessing manufacturability takes the geometric dimensions into consideration. A price is displayed only if the assessment is positive.

At this stage of development, cloud manufacturing platforms still have some limitations. So the answer to the above-mentioned question may not always be final.

Combining the answers with logical thinking, a client can use this assessment for redesigning the parts if necessary.

Sharing the Load

Cloud manufacturing helps to keep the lead times low by distributing work evenly.

An example:

A person orders 1000 parts. Manufacturer A has the capabilities to perform it but the production is full for the moment.

The info about availability is on the cloud.

Then we have manufacturers B and C who are also partners. Although neither of them has the capacity to perform the job on their own, the order will be divided between the two.

This way the order can be sent to production without waiting for manufacturer A to finish his current job.

Such work would be tedious manually but simple for an always-informed manufacturing platform.

Service Oriented Manufacturing

Manufacturing is usually production oriented. This means that the companies providing the services are only focusing on one aspect of the process.

Cloud manufacturing is looking to change that by offering resources and capabilities at the same place. Also, many manufacturing platforms take care of the delivery of the goods instead of leaving that to the customer.

Such a step forward leads to a more compact and easier-to-manage solution.

Volumes as Leverage

Cloud manufacturing platforms can accumulate large numbers of orders, making them valuable partners for production companies.

Such volumes make a great leverage in bargaining cheaper prices.

Manufacturing platforms often use pay-as-you-go model for profiting, adding an extra % to the final cost. Still, with their initial discounts, the final price for the customer is better than they could negotiate on their own. And this applies to cases where they could find a similarly-priced manufacturer in the first place.

Often, small orders are also accumulated to make up a large one for better material usage. Less scrap is another way to achieve better prices.

Capabilities

Extensive partner networks ensure the possibility to produce a large variety of parts.

Gathering a lot of manufacturers with different expertise and machinery under one name, the customer can get hold of the best equipment without much hassle.

Cloud manufacturing platforms have the data about possibilities and limitations. Thus, they can direct jobs to relevant partners only.

Less Points of Failure

As stated before, cloud manufacturing encompasses all steps from quoting to delivery. Therefore, there is only one point of contact.

This means that the responsibility also lies with one company and dealing with reclamations, delays, etc. is that much easier.

Short Go-To-Market Times

Having the possibility to quote and send parts to production without first establishing connections in the industry makes short go-to-market times possible.

For prototyping, iterations and first full products, cloud manufacturing is the perfect answer.

The same applies to on-demand manufacturing.

Only for large-scale production, it makes sense to really push for a large procurement department with the sole responsibility of securing the best deals. Volume is the key here and gives the possibility of negotiating even better prices on your own.

Keeping the Focus

The key cloud manufacturing provides, is the one unlocking more resources.

At SMEs, the responsibility of finding manufacturers often rests with design engineers. Outsourcing this obligation to a 3rd party leaves more time for the engineers to provide better solutions.

Who Is Cloud Manufacturing For?

Cloud manufacturing may sound intimidating because it’s new. Our experience with constantly growing complexity in tech creates associations with steep learning curves.

With cloud manufacturing, the contrary is true. The systems are very easy to navigate and make sense of.

Therefore, it does not need a lot of resources even in the first steps. The simplicity makes it suitable for a variety of people in need of manufacturing services.

Businesses

This is especially true for SMEs. Large corporations with high volumes can probably get greater discounts working on their own.

For SMEs, outsourcing this job makes a lot of sense. They don’t have the production volumes to negotiate for lower prices. Manufacturing platforms can use this leverage for them.

Bespoke solutions are the not the future any more, they are the present. With each job requiring new prices, it can amount to a lot of work. Instant pricing helps these companies to stay competitive with cost-efficient procurement processes.

Also, prototyping a few parts can be difficult because many manufacturers just reject such jobs. Cloud manufacturing platforms add those parts to larger orders, thus keeping the final price lower.

Starting Entrepreneurs

As we talked before, cloud manufacturing clearly reduces the go-to-market times.

Someone with an idea can now bring it to life without having any previous industry connections. They can still find their way to the best pre-vetted manufacturers nearby or faraway, depending on the final delivery destination.

This also makes it possible to, for example, start selling your products world-wide from the get-go. Setting up an online shop is the easy part. Now there is no need to build up a large stock and start transporting those things from the warehouse.

Make them nearby your customer and give up on renting a warehouse. This already covers the slightly higher costs of lower-volume production while mitigating the risk of holding large quantities in stock.

Engineers

So of course this applies to engineers who have to take care of manufacturing outsourcing working at the aforementioned businesses.

But there’s another side to it.

Any engineer who focuses on providing great results with low costs can now apply the pay-as-you-go system without “going anywhere”. The quoting system is free to use and helps them optimise the design for cost when comparing materials, thicknesses and different layouts.

Hobbyists

Hobbyists find pretty much the same perks with cloud manufacturing as starting entrepreneurs. Many need only a few pieces for a model plane, a new outdoors BBQ or a doghouse.

They can now turn to someone who can definitely assure quality for only a small one-time order.

We hope this was usefull to you. If you are interested in testing such a platform, you can sign up for free on our website and start uploading your files for instant pricing.