Ultra-thin and Flexible Smart Sensors for Early Detection of Leakages

Leaking fluids can wreak havoc if not detected at an early stage. This article showcases ultra-thin and flexible leak-detection solutions that can stick to any surface and immediately alert users in case of a leakage.

Continued research in materials has led to walls, containers, pipes and other surfaces becoming more resilient to leakages.[1] However, even with the best infrastructure, leakages eventually take place. Insurance companies pay out £1B annually on claims relating to water leak damage in the UK alone.[2] Claims related to leaks make up about 40% of all the claims presented to commercial insurers in the US each year.

In this article, we explain how buildings can “smartly” detect, even the smallest of leaks with the help of low-cost, ultra-thin and flexible printed sensors in real time. We’ll use the examples of water leak sensing products by LAIIER and OKdo to see how smart “Surface to Cloud” technologies are used in different areas to prevent damage by detecting leaks early. We’ll also have a look at the different cases where the technology has been successfully applied.

Conventional Methods for Detecting Water Leaks

Detecting water leakages typically requires installing a setup to check the flow of water within a pipe. The flow of water can be measured with the help of a turbine fitted installed inside the pipe. Whenever an abnormal flow of water is detected, the system alerts the users and cuts off the water supply. But since installing a turbine inside the pipe require obstructing the flow of water, companies have come up with ways to detect leaks using ultrasound and other non-invasive methods.

Unfortunately, these methods are not suitable for all applications because of limitations such as high cost, difficult installation process, size constraints, low accuracy, low sensitivity and slow response. Ultra-thin printed smart leak detection sensors overcome many of the common limitations associated with the existing water leak detection methods.

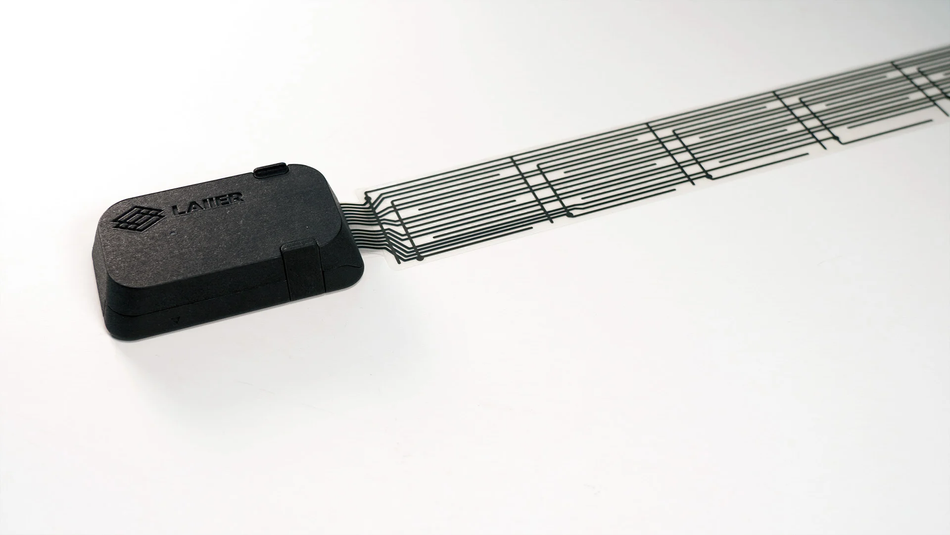

The Ultra-Thin Printed Smart Leak Detection Sensor

Smart leak detection sensors take an entirely different approach to detecting leakages. These sensors can stick to surfaces such as the exterior of pipes, below dishwashers/washing machines, over the ceiling, and in other places where the presence of water needs to be detected. For applications with an intermittent presence of water, the smart leak detection system can be customised to sync with the schedule and raise warnings only if water is detected at an unexpected time/place.

Whenever the sensors detect a leakage, they relay the information to the supporting electronic hardware that ultimately pushes an alert to the users and/or a third party system which can cut off the water supply. The whole process is carried out by three components that make up the smart leak detection system. They are:

Ultra-Thin, Flexible Printed sensors

Printed sensors are the most fundamental building blocks of flexible IoT applications. Their ability to sense changes in resistance or capacitance around them makes them capable of detecting/measuring various physical quantities and phenomena –including water leakage. Printed sensors are extremely versatile and can be built to fit various surfaces.

Using a conductive ink made of carbon, structures are printed over a thin sheet of polyethene terephthalate (PET) material (also widely used for making bottles). These printed carbon structures act as electrodes, and when a drop of water falls over them, the resistance between them changes, which is used as a sign of a leak.

These sensors can achieve a sensitivity as high as 0.1 ml of water per metre square. The arrangement of electrodes over the flexible sensor also allows for the detection of false-positive alarms, i.e. the system can make out the difference between continuous leakage and a one-time spill.

The form factor of a printed sensor drives the functionality of the product. The printed sensors are much easier to customise compared to the other hardware. With a little alteration, printed sensors can be used to detect (and measure) the leakage of other substances apart from water.

Electronic hardware

The electronic hardware includes batteries, amplifiers, analogue-to-digital converters (ADC), connectors, a controller and other supporting circuitry required for the operation of the printed sensor. The collective purpose of the amplifiers and ADCs is to convert the readings of the printed sensor into a digital form and pass it to the controller for further processing. The controller passes the information to the connectivity module and triggers programmed events and alerts.

The connectivity module can make use of low-power communication protocols such as Long Range Wide Area Network (LoRaWAN) which is a wide-area networking protocol built on top of the Long Range (LoRa) radio modulation technique. It manages the connectivity between end devices and network gateways.

The hardware is made to be extremely energy efficient so that it can last for multiple years on a single charge.

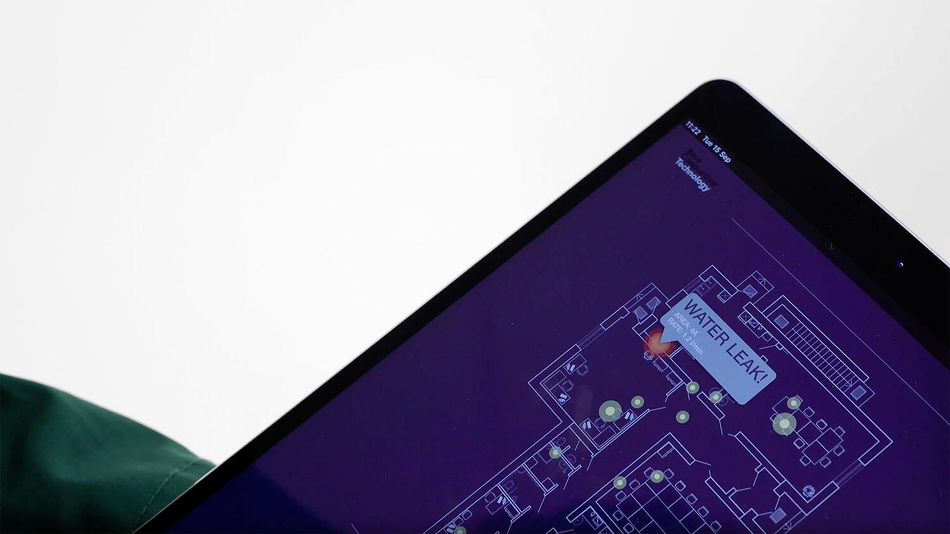

Surface to Cloud Connectivity and APIs

This is the application layer that can be customised for users. Hardware manufacturers provide a set of APIs that can be integrated with different IoT/cloud platforms to facilitate the collection and logging of data. It is possible to set up the system in such a way that it immediately sends alerts to users when a leak occurs and shuts down the appliance/water supply causing the leak. The possibilities are endless.

The Installation Process

Smart leak detection sensors are installed like a second skin over flat, curved or even irregular surfaces. They are self-adhesive in nature and stick to surfaces just like a tape/sticker where leaks are expected to happen. The PET material that these sensors are made of is extremely robust, making the structure scratch and chemical-resistant. The stickers are field trimmable –they can not be torn by hand but be cut by a pair of scissors.

The printing processes are incredibly scalable. Once the leak detection system is set up, it's possible to increase its area coverage with a marginal cost increase. As the process improves, the cost per unit area keeps dropping.

Applications and Use Cases

Water leakages can take place anywhere at any time. Here are some examples of the most common places where printed leak detection sensors can prevent massive damage:

Dishwasher Leaks and Laundry

Because of busy schedules and long working hours, more people are turning to home appliances like smart dishwashers. A defect in the pump, supply/drain hose, door or any other part of the dishwasher can cause a leak which can be challenging to detect. Typically it would involve running the machine in the leaking state and manually inspecting for the defect. Such a leak harms not only the dishwasher but also the walls, floor and other appliances in close proximity.

Smart leak detection sensors can be applied around the dishwasher’s body to detect even the smallest of leaks at a very early stage. Smart leak detection sensors pinpoint the exact location of the leak and push the data to the cloud to notify the owners.

The same sensors used for detecting water leakage can also be used for measuring liquid levels. Commercial laundry companies make use of different liquid detergents for whitening, conditioning, disinfection or low-temperature service. The exact amount of detergent required for each wash is difficult to predict; hence manually dispensing the detergent incurs losses for laundry service. Having an accurate level sensor ensures the quantity of liquid detergent dispensed is optimum and the owners are aware of when new stock will be required.

Flat Roof Leaks

It’s a well-known fact that flat roofs are susceptible to leaks. Green roofs with a thin layer of soil and plants over them are even more susceptible compared to regular flat roofs. Leak detection sensors can be installed on the surface of the roofs or deep below the layers of the roof to get alerts about a leak. This way, leakages can be detected long before they cause damage to the building’s structure.

Exposed Pipe Leaks

No matter whether the pipes are made up of steel, copper or polyvinyl chloride (PVC), after they are installed, leakage issues get unavoidable a few years down the line. Burst/damaged pipes are probably the most common sources of leakage in both domestic and industrial spaces.

Leak detection sensors can be placed onto the pipes as tapes to continuously monitor the areas that may not be easily accessible. These devices provide a cost-effective and scalable solution for the early detection of leakage in pipes.

Under Sink and Tanked Water Heater Leaks

Water feeds, and drainage systems are both sources of potential leakage. In many cases, the performance of the sink remains unchanged even in case of leaks making it difficult to know when such an event occurs. It’s only when the effect of the leak spreads beyond the sink to walls, furniture and other items that one can visually detect it.

With the highly sensitive water leakage sensors, leakage of as small as just two drops can be detected in real-time. These water leakage sensing solutions can run off a tiny battery and still last for multiple years together, letting you avoid the risks of installing another live electrical supply in the bathroom.

Similar technology can be deployed to check leakages in tanked water heaters where the leakage is a common problem. In water heaters, leakages can take place in the water supply/drain line, water tank and valves. Detecting a leakage in the heater is possible with a flowmeter, but the solution is expensive and does not detect the leakage quickly. Hence, water leakage sensors can be used as better alternatives.

Marine Exhaust Scrubber Leaks

Leakages in ships can be life-threatening. Even with frequent manual inspections, there are chances of leakages in areas that are difficult to reach. A small missed leak can develop into a major incident jeopardising the safety of people onboard.

Multiple methods, such as temperature sensors, pressure sensors, flow meters, acoustic imaging, thermal imaging etc., are used to keep leakages in check. Alongside the existing arrangements, thin and flexible leakage sensors can be installed to detect issues in real-time.

Oil Leaks in Transformer and Wind Turbines

Transformers are the electrical machines used to step-up/step-down the voltage and current levels of electrical power. These machines enable efficient transmission and distribution of electrical energy through the grid. During operation, transformers generate heat which must be dissipated safely. For this purpose, these transformers are filled with mineral oil.

Oil leakages from transformers are potential fire hazards and hence, must be dealt with very carefully. Leak detection sensors can be adapted to sense oil leakage and provide a solution for instantaneously pinpointing the source of the leak and taking the transformer off the grid.

Oil is also used as a hydraulic fluid or a lubricant in turbines. Considering the cost of equipment used for building the turbines and the scale of operations, oil leaks here could be catastrophic. Specially designed printed sensors can turn the surfaces of the turbine smart to detect such an occurrence.

OKdo and LAIIER partner to build Ultra-thin and Flexible Smart Leak Detection Sensors

OKdo has announced a manufacturing and distribution partnership with LAIIER to incorporate intelligent sensing technology into equipments and buildings to predict, prevent, and manage water leaks. With printed electronics and cutting-edge IoT technologies, smart sensing solutions by OKdo and LAIIER offer cost-effective ways for commercial property insurers, facility management and other customers seeking to make surfaces that detect leakages early. The smart leak detection solutions can stick like tape almost anywhere and accurately detect as few as two drops of water.

The partnership between OKdo and LAIIER enables customers to collaborate with skilled engineers at OKdo to get customised hardware designs to suit different requirements. The tech brands combine their customer-centric approach by enhancing their leakage sensing solutions to detect more than just water. By making tweaks to the existing technologies, they can be functionalised to sense bulk solids such as grains, sugar, powder, hydrocarbons, as well as other liquids such as oils or fuels.

Surface to Cloud predictive maintenance and continuous monitoring solutions by LAIIER and OKdo can significantly reduce the cost of damages due to leakages in smart buildings and industries. For more details, visit: Connected Smart Building Solutions | Automation Systems & Technology | OKdo

Conclusion

It’s always good to know where to look for when there is water leakage; however, what’s better is to know in advance where it might occur. Smart leakage detection solutions like the ones developed by LAIIER and OKdo make it possible to detect and even predict leakages by picking up early signs.

The ultra-thin and flexible smart leak detection sensors can stick to surfaces around areas vulnerable to leaks and turn them smart. The resulting smart surface can then alert users in case of a leak. Just like every screen eventually became a touchscreen, every surface could end up becoming smart over the years to come.

The Rock Engineering Challenge

The Rock Engineering Challenge invites engineers, entrepreneurs, inventors, and developers to submit an idea for a part, product, or system that takes advantage of the ROCK single-board computers.

- The first 500 valid entries will receive a ROCK board of choice worth $45 - $159.

Simply tell us what you are working on, and we'll send you a piece of cutting-edge hardware to bring your ideas to life. - The most-cutting edge entry will be rewarded with a grand prize of a $50,000 partnership with electronics company OKdo to scale up their project idea.

The challenge is now open until April 12th, 2023.

READ MORE ON THE CHALLENGE HOMEPAGE!

About the Sponsor: OKdo

OKdo is a brand delivering a unique combination of hardware, software, development, and manufacturing services to help customers turn their innovative ideas into commercial realities. The company has been endorsed by technology giants such as Arm, NXP, Broadcom, Intel, and SEEED. OKdo partners with different brands to bring the latest and most innovative IoT and SBC products to people around the world.

References

[1] Innovation in Waterproofing Technologies, Constro Facilitator, [Online], Available from: https://constrofacilitator.com/innovation-in-waterproofing-technologies/

[2] IoT Enabled Water Leak Detection Equipment For Commercial Buildings, OKdo, [Online], Available from: https://www.okdo.com/smart-world/commercial-water-leak-detection/

[3] LoRaWAN World Expo 2022: Using Sticker Sensors to Connect to the Cloud - July 7, 2022, LoRa Alliance - YouTube, [Online], Available from: https://www.youtube.com/watch?v=v9zRoqsMwPY&ab_channel=LoRaAlliance