Streamlining Cobot Design with Digital Platforms and Online Resources

Digital platforms have profoundly transformed the design process for cobot motor drives, enabling engineers to streamline workflows, enhance precision, and rapidly adapt to the evolving demands of the industrial landscape.

Collaborative robots, or cobots as they're popularly known, have ushered in a new era of automation. Unlike traditional robots which operate in isolation, cobots are designed to work alongside humans in a variety of industrial settings. This collaboration offers numerous advantages – from increasing productivity and reducing errors to taking over repetitive tasks, allowing human workers to focus on more complex functions. Their increasing adoption signifies a transformative shift in the industry, as businesses continually search for avenues to optimize operations.

This article aims to shed light on the journey of cobot design, with a particular emphasis on the electrical drive design that powers these robotic systems. As with any technological marvel, the road to designing an effective cobot and its drives isn't without hurdles. However, the digital age brings forth a suite of online tools and resources that promise to revolutionize this process. From streamlining component selection to offering real-time analytics, these digital platforms play an instrumental role in accelerating the design process. By minimizing design iterations, they bridge the gap between a concept and its tangible realization, ensuring that the final product is both efficient and reliable. Join us as we explore how online tools and resources are shaping the future of cobot design.

Challenges in Cobot Design

In crafting the intricate cobot systems, engineers face challenges across various domains. Some of them are:

Mechanical Constraints: Mechanical design in cobots ensures the robustness and precision necessary for seamless operation. In many industrial settings, cobots need to be integrated with pre-existing machinery and systems. Ensuring this seamless integration without disrupting existing workflows presents a unique challenge.

Control Electronics and Software Integration: Acting as the cobot's nervous system, control electronics work alongside integrated software to interpret signals and coordinate precise movements. Challenges in this domain include developing systems that ensure smooth communication between sensors, actuators, and the processing core, while managing real-time data processing with minimal latency. Additionally, engineers are tasked with ensuring these systems adhere to rigorous safety and reliability standards essential for effective human-robot collaboration.

Power Electronics and Motor Drive Design/Selection: In the realm of cobot development, the domain of power electronics and motor drive design embodies a complex set of challenges that are central to the operational integrity of these advanced machines. The selection of components, effective heat management, and the integration of compact yet efficient cooling and packaging solutions are just the tip of the iceberg. Additionally, ensuring the electrical design is both efficient and adaptable to fluctuating power demands without sacrificing endurance, requires a nuanced approach.

The process of creating a cobot involves multiple stages beyond component selection, such as measurement, protection, gate driving, and signal processing. The role of the power electronics engineer is pivotal, focusing on the power stage of the drive while other teams may view the drive as a complete unit that meets specifications. These teams may not be familiar with semiconductor companies nor are they involved in selecting electronic components, which can be intricate. This highlights the importance of expertise from companies like Nexperia and Sense and Drive aiding power electronics engineers in their complex selection process.

While mechanical design establishes the essential structure, the complexity of control electronics, and the crucial nature of power electronics, along with the careful design/selection of motor drives, emerge as areas requiring specialized attention in our discussion. The upcoming case study will discuss these challenges and the innovative solutions applied in more detail.

The intricacies involved in cobot design also underline a pressing need for digital intervention. The traditional trial-and-error approach is not just cumbersome but also poses risks in terms of cost overruns and delays. In a rapidly evolving industrial landscape, such delays could translate into missed opportunities.

Online Tools: The Catalysts of Streamlined Design

Digital platforms have become critical in cobot design, transforming the way components are selected and evaluated. Engineers now leverage extensive digital databases for rapid searching and comparison, replacing time-consuming manual catalog reviews. Real-time analytics further enhance decision-making, providing deep insights into component synergy and performance, allowing for more informed and confident design choices.

These online tools also offer sophisticated simulation capabilities, enabling the prediction and troubleshooting of potential issues virtually, thereby reducing the need for physical prototypes. Interactive features like 3D visualizations and virtual testing create a comprehensive view of the cobot system, addressing spatial constraints and optimizing functionality. These innovations have elevated digital resources from useful aids to fundamental elements in efficient and precise cobot design.

Online tools have shifted from being mere conveniences to essential cornerstones in cobot design. They offer a bridge over traditional challenges, bringing in an era where design is not just faster but also more precise, efficient, and forward-thinking.

Component Selection with Online Simulators

Online simulators have revolutionized cobot component selection by replacing manual guesswork with precise virtual testing. These advanced tools allow engineers to assess how each component functions under simulated real-life conditions, streamlining the selection process by preempting the need for trial-and-error methods.

These simulators excel in emulating real-world dynamics, enabling engineers to modify conditions and observe component reactions. This insight is crucial for evaluating component durability and compatibility, leading to resilient and adaptable cobot designs. Furthermore, the iterative nature of simulators means designs can be refined continuously as new information or requirements arise, guaranteeing that each sensor, actuator, or processor is optimally integrated for peak efficiency and safety in human-robot interactions.

“Key factors in power device selection include dominant losses (conduction or switching), space, and price constraints. These are crucial for product market success, with power stage component selection being of utmost importance”. - Milan Darijevic, Sense and Drive

For example, the choice of sensors within the cobot's design is paramount; as in selecting the right torque sensor impacts the cobot's ability to interact safely and effectively with humans by accurately measuring and responding to applied force and pressure.

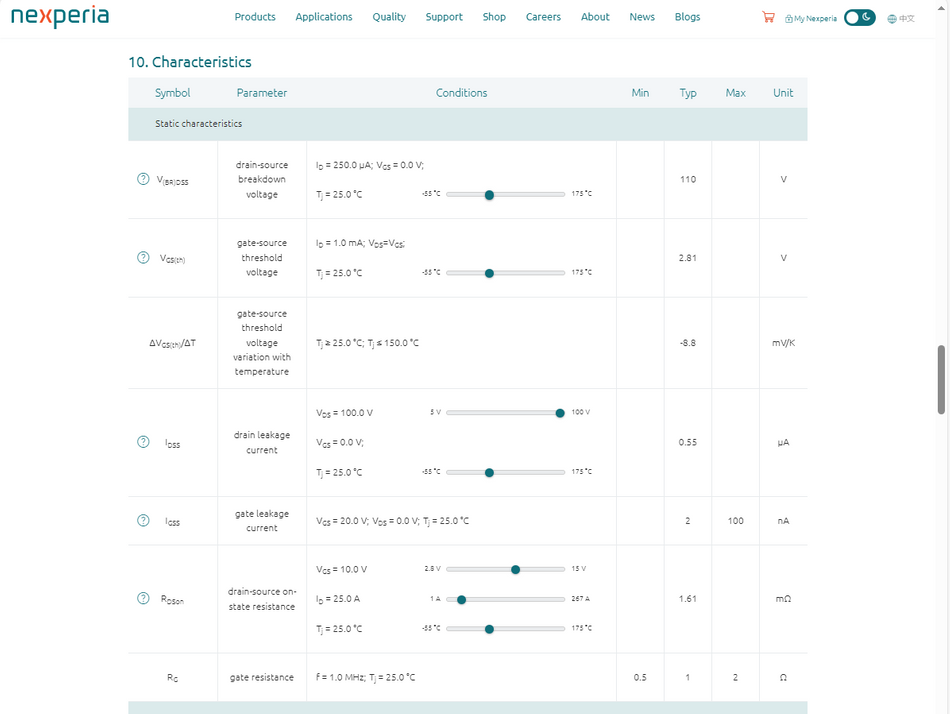

Understanding Dynamic Component Behavior with Interactive Datasheets

The age of static datasheets—mere documents providing a fixed snapshot of component specifications—is fading. As the complexities of modern cobot design unfold, there's an increasing need for tools that provide a more dynamic, interactive understanding of component behavior. Enter interactive datasheets.

Interactive datasheets are a leap ahead in the way engineers visualize and interpret component specifications. Unlike their static predecessors, these datasheets come to life, allowing users to modify conditions and observe how components respond. Whether it's altering voltage levels, tweaking temperature parameters, or adjusting load conditions, engineers can instantly see how a component would behave under different scenarios.

This immediate visual feedback is a boon for design accuracy. Instead of laborious manual calculations or estimations, engineers receive real-time insights. For instance, with interactive MOSFET datasheets, engineers can immediately determine how the device’s efficiency is affected by temperature fluctuations or how its power consumption changes with workload variations.

Furthermore, this dynamic representation helps in bridging the gap between theory and application. Engineers can confidently make design choices, armed with the knowledge of how components will operate not just in ideal conditions, but in the multifaceted environments they're destined for.

In the broader context of cobot design, the role of these datasheets becomes even more pivotal. As cobots are required to function seamlessly alongside humans in diverse industrial settings, understanding the nuances of each component's behavior is crucial.

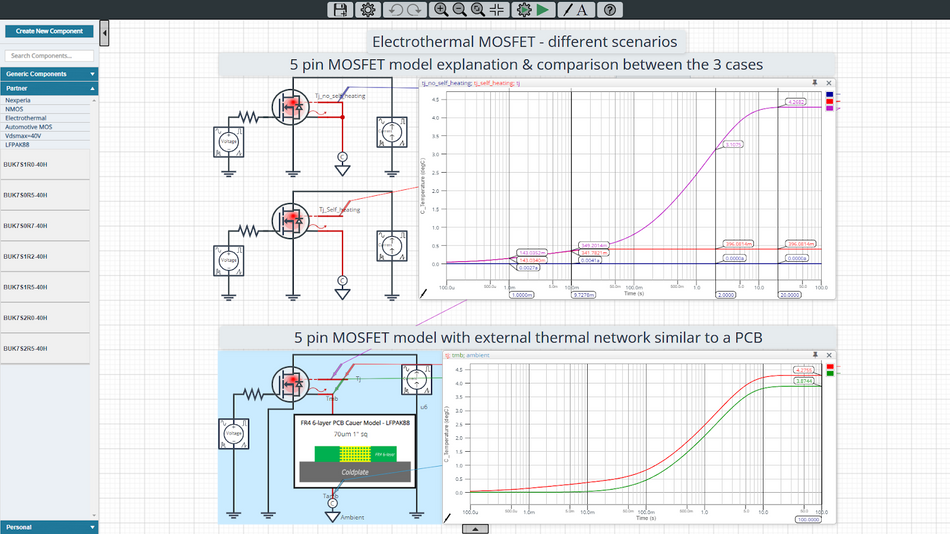

Accurate Preliminary Validation with Electrothermal Component Models

The drive to innovate and produce cutting-edge cobots comes with its set of challenges, and one such challenge is ensuring the components function optimally in real-world conditions. Here, Electrothermal models play an invaluable role, serving as a linchpin in the early stages of design validation.

Electrothermal models go beyond traditional electrical simulations by factoring in the interplay between electrical operations and thermal behaviors. This dual consideration ensures that components not only perform as expected electrically but also maintain their functionality and safety when exposed to varying temperature conditions. Electrothermal models fuse electrical and thermal simulations, delivering a holistic view of component behavior in multiple ways such as:

Integrated Simulations: Unlike separate electrical or thermal simulations, Electrothermal models provide simultaneous insights. They factor in the mutual interactions of current flow, voltage drop, and thermal dissipation, which are all intertwined in real-world scenarios.

Identification of Hotspots: By simulating the thermal distribution alongside electrical activity, these models can reveal the temperature performance of a device. This insight is crucial for engineers to make informed decisions that prevent premature failures by ensuring the entire device operates within its thermal limits, thereby averting issues due to excessive heat.

Optimizing Heat Management: With an accurate understanding of where and how heat is generated, engineers can devise more effective heat management strategies, be it through improved layout design or the addition of thermal management components like heat sinks.

Ensuring EMI (Electromagnetic Interference) compliance and EMC (Electromagnetic Compatibility): Electrothermal simulations can be paramount in preempting EMI and ensuring EMC. By observing how components behave electrically within their thermal operating ranges, potential sources of interference can be identified and mitigated.

By embracing Electrothermal component models, engineers are not just making a choice for better component validation; they are opting for a comprehensive, multi-faceted approach to design. This ensures that the resultant cobots are not only functionally proficient but are also robust enough to handle the demanding environments they operate in.

Quick Learning Videos and Interactive Application Notes: The Learning Curve Redefined

In today's fast-paced technological landscape, rapid knowledge acquisition and application are paramount. To cater to this, companies like Nexperia have introduced a suite of educational resources: Quick Learning Videos and Interactive Application Notes. These tools are designed not only to disseminate knowledge but also to instill a deep understanding of complex component behaviors and their applications.

Quick Learning Videos: These concise yet comprehensive videos are designed to provide engineers with bite-sized insights into key component features, applications, and best practices. Instead of trawling through lengthy documents or attending exhaustive seminars, engineers can quickly grasp essential concepts, ensuring they're always equipped with up-to-date knowledge that's relevant to their design challenges.

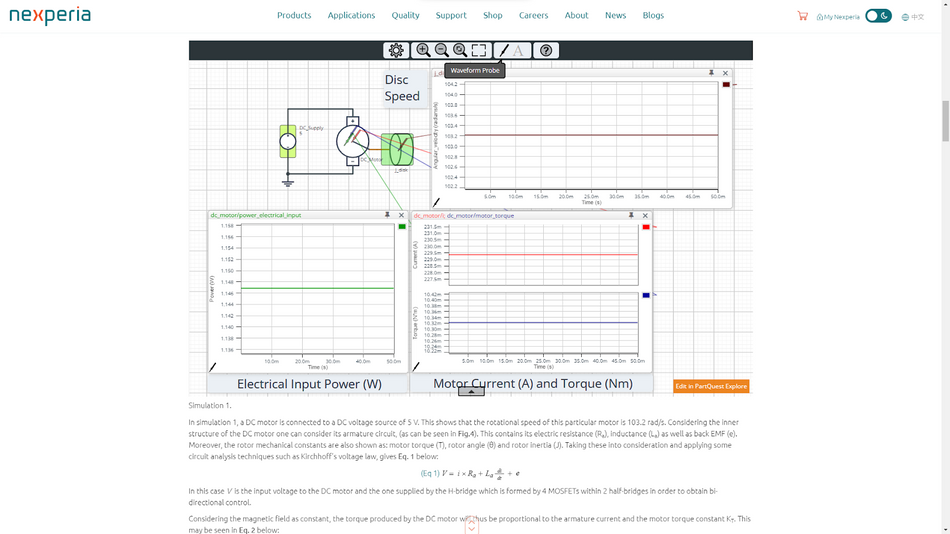

Interactive Application Notes: Traditional application notes offer static insights, which, while valuable, might not cater to every unique scenario an engineer faces. Nexperia's interactive version elevates this by allowing engineers to tweak parameters, observe results, and thus, gain a hands-on understanding of component behaviors and applications. This interactive approach ensures engineers not only know the "what" but also the "why" and "how" behind component functionalities.

Combined, these tools form a potent knowledge base, empowering engineers to delve deeper into their designs. They facilitate not just theoretical understanding, but a practical, hands-on grasp of how components function, how they can be optimized, and how they fit into the larger cobot design framework.

Designing Power Electronics Systems and Drives for Cobots: A Case Study

When an application engineer sets out to design a power electronics drive for a cobot, they embark on a complex and multidisciplinary task. The design flow often begins with a clear understanding of the hardware design requirements derived from the application level, leading to the selection of motor types and defining the drive's ratings. The following sections outline the methodologies and challenges application engineers face, highlighting how collaborations with semiconductor leaders like Nexperia and the expertise of power electronics innovators at Sense and Drive aid in overcoming these hurdles.

Defining Specifications

The engineer starts by determining critical drive specifications, such as DC-link voltage, peak and nominal power, drive ambient temperature ratings, and maximum phase current fundamental frequency. These parameters help ascertain control and switching frequencies, temperature, and current ratings for power devices.

Challenge of Component Selection

One of the first hurdles is selecting the appropriate power device. The choice is influenced by the expected dominance of conduction versus switching losses, space constraints, and budgetary considerations. For low-voltage motor drives, silicon FETs have been identified as the most suitable due to their performance and cost-effectiveness.

Customizing for Cobot Dynamics

Cobot drives differ from standard industrial drives, especially in terms of power cycling. Cobot drives require a unique approach to power management. They need to be designed to cope with fluctuating power demands based on the dynamics of the system. Typically, a cobot will have a normal operating power level and a peak power level that can be twice or even three times as high. These peak power levels occur briefly, for instance, a cobot may run at 1 kW for 1 millisecond, and then surge up to 2.5 kW for just 0.3 milliseconds during intensive tasks.

The electronic components that control power, specifically the Field-Effect Transistors (FETs), must be capable of handling these very brief, yet intense, power spikes without failing. Moreover, they need to maintain this performance consistently over time, as cobots are expected to operate non-stop in conditions that can reach up to 100°C, often without the benefit of cooling systems like fans. This continuous power cycling challenges the design to ensure that there is no overheating that would compromise the cobot's operation.

Tackling Electrical and Thermal Constraints Together

Modern cobot drives incorporate surface-mounted device (SMD) components, which presents a unique challenge as electrical and thermal constraints are on the same plane—the PCB surface. High power density and spatial limitations dictate stringent requirements for FET package selection and cooling strategies.

When selecting power devices, understanding the trade-off between device geometry and its impact on conduction and switching losses is crucial. The geometry of a power device dictates the relationship between conduction losses, characterized by on-resistance (RDS(on)), and the parameters critical for switching losses, such as switch capacitances and voltage thresholds. This relationship should guide the selection process based on the application's specific requirements.

For instance, in a 2 kW high-speed medium voltage drive, a higher RDS(on) might be acceptable. This is because the phase current amplitudes are lower, which means the drive can afford to prioritize FETs with superior switching characteristics over lower conduction losses. High switching frequencies are essential here to reduce phase current harmonics and DC-link voltage ripple.

Conversely, in a 24 V drive handling 60 A of phase current, the scenario changes. The machine inductance likely permits the use of a very low switching frequency, which makes conduction losses the primary concern. In this case, selecting FETs with the lowest possible RDS(on) is crucial to efficiency.

Additionally, in systems where conduction losses are significant, like the 24 V, 60 A drive, paralleling FETs may be beneficial to further reduce these losses. However, paralleling necessitates meticulous attention to the FET package and cooling design to prevent temperature-induced variations in RDS(on). These variations can lead to uneven current sharing among the FETs, undermining the benefits of parallelization. Therefore, ensuring that FETs in parallel operate at uniform temperatures is vital to maintain the integrity of the parallel configuration and the overall efficiency of the drive.

Mitigating Switching Losses

In high-speed drive applications, a fast control loop is essential, necessitating a high switching frequency. For motor drives utilizing power MOSFETs, the typical switching frequency ranges from 25 kHz to 50 kHz. However, drives equipped with GaN FETs can operate at much higher frequencies, up to 400 kHz, enabling even faster control responses.

The drive's design must take into account the parasitics introduced by PCB layout, which can affect FET switching performance, leading to higher switching losses and reduced efficiency. Striking a balance between electrical and mechanical constraints is crucial, and sometimes, compromises are necessary to meet system-level requirements like cost and volume.

Leveraging Advanced Component Solutions and Services

To address these challenges, companies like Nexperia provide FETs with robust switching performance that are less sensitive to PCB parasitics. This allows for more flexible gate driving circuit placement and the integration of custom heatsink adapters to efficiently transfer heat from the power stage to larger cooling elements. Their LFPAK package design facilitates heat transfer to both the heatsink and the PCB, offering mechanical flexibility.

In the specialized landscape of cobot drive development, manufacturers typically seek out expert partners to furnish custom power electronics that align with their unique requirements. Nexperia and Sense and Drive stand out in this niche, offering bespoke solutions that blend cutting-edge technology with extensive industry experience. Their approach not only provides cobot manufacturers with tailored components and drives that enhance performance and efficiency but also ensures complete transfer of intellectual property. This strategic collaboration facilitates manufacturers' autonomy over the production and ongoing enhancement of their products, positioning them at the forefront of innovation in the dynamic cobot ecosystem.

Nexperia’s Advanced Design Tools: Pioneering the Future of Cobot Design

Nexperia stands at the forefront of technological advancements in cobot design, with its suite of advanced design tools reflecting a dedication to pushing the boundaries of what's possible. These tools are not mere add-ons but integral components that elevate the entire design process. They offer several advantages such as:

Unified Design Environment: Nexperia's platform offers a cohesive environment where engineers can seamlessly transition between simulations, datasheets, and learning resources. This unified approach fosters efficiency, ensuring that engineers have everything they need at their fingertips.

Intelligent Recommendations: Nexperia's tools can proactively suggest optimal components and design tweaks based on user inputs and past successful designs. This approach minimizes guesswork, ensuring designs that are both innovative and reliable.

Collaborative Features: In an era where teamwork is essential, Nexperia's tools support collaborative design. Engineers can share their designs, get feedback, and iteratively refine their work, all within the platform. This collaborative framework ensures that the resultant cobots are a product of collective expertise.

Real-time Component Availability and Sourcing: Beyond just design, Nexperia's platform offers real-time insights into component availability, lead times, and even potential alternatives. This ensures that once a design is finalized, the transition to production is swift and hiccup-free.

Remote Accessibility: With readily available online tools, engineers can access Nexperia’s design tools from anywhere, be it the office, home, or on the go. This flexibility ensures that the design process is uninterrupted, fostering faster turnarounds.

By integrating these advanced features into their platform, Nexperia is not merely offering a toolset but is shaping the future of cobot design. It's a vision where rigorous design methodologies meet cutting-edge technology, culminating in cobots that are adept, efficient, and ready to meet the dynamic demands of the modern industrial landscape.

Find out more about Nexperia’s advanced support tools here: Advanced Support Tools - Nexperia. And to find out more about Nexperia’s product solutions for your motor drive design in a cobot application click here: Ensuring reliability for cobot designs.

Conclusion

The trajectory of cobot design is on an upward swing, becoming ever more integral in the fabric of industrial automation. The necessity for advanced design tools and methodologies is paramount in meeting the demands of this evolving field.

This article highlighted the significant edge that comprehensive digital resources offer to engineers. Moreover, the specialized expertise of industry veterans like Nexperia, with their insights into MOSFET applications, and the tailored, innovative power electronics solutions from Sense and Drive, greatly enhance the cobot design process.

By leveraging such expert collaborations, the industry is poised not only to fulfill but to exceed the current and future requirements of cobot technology, crafting solutions with unmatched precision, efficiency, and foresight.

About Sense and Drive

Sense and Drive DOO is a company based in Belgrade, Serbia, with focus on innovative technologies in the field of power electronics, such as integration of wide-bandgap semiconductors, complex converter topologies, state of the art measurement, driving and control techniques into new, market-ready solutions. Our team consists of experts with broad experience, gained worldwide in leading industrial and academic R&D groups. Our main mission is to optimize and boost productivity in power electronics research and development, helping our customers to integrate new concepts and technologies into next generation products, as well as to optimize the development cost and time to market.

Based on past projects, our experts gained wide experience in the fields of integrated motion control drives for robotic applications, wireless charging for medium-power industrial and low-power medical products, as well as in high-power traction automotive applications. Very important aspect in all these areas is careful component selection, with special focus on power stage components, i.e. power switching devices (Si, SiC and GaN FETs), gate drivers, as well as measurement circuits. With more than 10 years of experience on average, our team has developed specialized tools for critical component selection, which leads to optimal solutions regarding space, cost, efficiency and power density.

More about our partnerships and past projects can be found on our website, sensendrive.com.

About the sponsor: Nexperia

Headquartered in the Netherlands, Nexperia is a global semiconductor company with a rich European history and over 15,000 employees across Europe, Asia, and the United States. As a leading expert in the development and production of essential semiconductors, Nexperia’s components enable the basic functionality of virtually every electronic design in the world – from automotive and industrial to mobile and consumer applications.

The company serves a global customer base, shipping more than 100 billion products annually. These products are recognized as benchmarks in efficiency – in process, size, power, and performance. Nexperia's commitment to innovation, efficiency, sustainability, and stringent industry requirements are evident in its extensive IP portfolio, its expanding product range, and its certification to IATF 16949, ISO 9001, ISO 14001, and ISO 45001 standards.

Ensuring reliability for your cobot design