Podcast: Self Repairing Corrosion Coating

In this episode, we talk about a breakthrough research project that resulted in a corrosion protection coating capable of similar performance as current state of the art, lower cost per application, ability to self heal, and illuminates cracks/pits in the coating for easier detection.

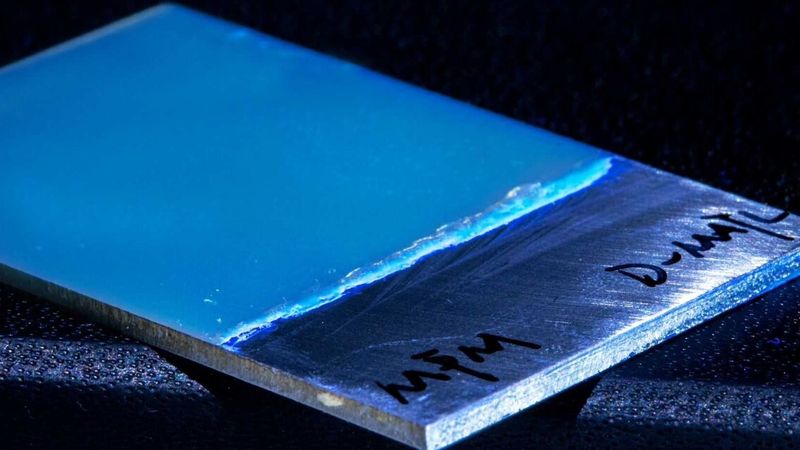

Fluorescent corrosion protection on a metal plate. (Photograph: Marco D’Elia / ETH Zurich)

In this episode, we talk about a breakthrough research project that resulted in a corrosion protection coating capable of similar performance as current state of the art, lower cost per application, ability to self heal, and illuminates cracks/pits in the coating for easier detection.

This podcast is sponsored by Mouser Electronics.

EPISODE NOTES

(3:26) - New corrosion protection that repairs itself

This episode was brought to you by Mouser, our favorite place to get electronics parts for any project, whether it be a hobby at home or a prototype for work. Click HERE to learn about how nanotechnology is being leveraged in the aerospace industry!

What's going on, folks? Welcome back to the NextByte Podcast. And this one, we're talking about an unsung hero of the corrosion world. PPM, the newest superhero in the nanomaterials realm. So, if material science is interesting to you, if you're curious about why we spent $4 trillion on a problem that we can't solve, and this is the episode for you, buckle up, let's get into it.

I'm Daniel, and I'm Farbod. And this is the NextByte Podcast. Every week, we explore interesting and impactful tech and engineering content from Wevolver.com and deliver it to you in bite sized episodes that are easy to understand, regardless of your background.

-----

Farbod: Okay, folks, as you heard, we're talking about materials, more specifically nanomaterials. But before we get down into the small scale, we're gonna go big, like very, very big, specifically, aerospace big, because today's sponsor is Mouser Electronics, you guys know, we love Mouser. If you're a fan of the podcast, you know that one of the reasons we love Mouser is because they're one of the world's biggest electronic suppliers. And what that means is that a lot of partners they work with, right. And through these partnerships, they get a little bit of insight into academia, latest trends in the industry, and then they write articles about what they know. So, the one that they wrote today that I thought was really interesting, and just generally applies, what we're gonna be talking about, is the potential for nanotechnology in the aerospace industry. So, we've done a bunch of like aerospace themed episodes, you know, that weight is very important, right? Because weight is going to determine how much fuel you're going to need to fly. If you're an airline, or even like someone that's delivering payloads to the International Space Station, in determines like, how cost effective it can be. So, the more weight you can save, the better. And this article, they talk about all these different lightweight lightweighting technologies that you can use and powered by nanotechnology. But they even go further than that. They talk about sensor systems that we can replace on, on aircraft because of nanotechnology. And one that I liked a lot was, there's all these architectures that we use on the modern aeroplane that can be replaced by very, very lightweight and novel NASA technology. And the one they talked about was graphene as a replacement for this heavy metallic structure that splits lightning as it hits an airplane. Pretty sick. And you know, you and I have a bias for our love of graphing, because that's the research we worked on. That's how we met each other. I think it's super dope. We're going to link in the in the show notes if you're interested in reading more. But, you know, if you're interested in how nanotechnologies can be applicable in your day-to-day life, you should definitely check this out

Daniel: On one of the things, I want to highlight from this article, right? It's called potential for nanotech in the aerospace industry. One of the big things they highlight is for protection against the elements, corrosion using nanotechnology. And that's actually the topic of today's episode. So, using nanotechnology to protect against corrosion. I think it's a perfect segue for us to start talking about this new superhero type corrosion protection that repairs itself.

Farbod: Some would say it's a good primer. Yeah, right. Yeah, look at that. So like Dan just said, we're talking about corrosion protection. And this is coming out of ETH Zurich, the laboratory for multifunctional materials. And by now you should know I love a good story. And this has a great, great story. So, we got this laboratory. There's these two main researchers are working on it. It's Markus. I'm sorry if I butchered the last names, but Niederberger and Walter Caseri. And what they're trying to do about 10 years ago now is to synthesize nanoparticles, and they're using these very special organic solvents to do that, until it accidentally polymerizes when they're doing testing, that means it solidifies. They weren't really trying to do that, it just kind of happened. But once they started examining it, it had some very interesting properties like it had fluorescence, which means that it was glowing when all the material properties indicated that it should not be doing that. It also had really high thermal stability. So, at very high temperature ranges, material properties stayed the same. So, because of this, there were like, look, this there might be some potential here and they the name of the material is Poly(phenylene methylene), aka PPM.

Daniel: We'll stick with PPM because yeah, probably finally methylene is a bit of a tongue twister.

Farbod: It's a mouthful for sure. But they were like, look, there's probably some potential in this. Let's continue working on it. And they got this PhD student whose entire goal was to do improving the synthesis process. And then that PhD students successor, the one that kind of cracked crack the nut here was Marc D’Elia. And Marc's entire purpose was to find a good use case for PPM. Like they're like, hey, welcome to the program, find something useful that we can do with this.

Daniel: And I think, like, part of the context is interesting here. It was 10 years ago that they first discovered this PPM material. They've had a series of researchers, PhD students working on making a useful application for ppm for almost a decade. And what's crazy is when they first discovered it, and this is a quote directly from Niederberger, he said, this was unintentional and unwanted. And we don't know what to do with it at first. So, they're like, we didn't want to make this material. But turns out, it's actually kind of interesting. And it reminds me a lot of these other accidental discoveries that ended up revolutionising the way that we do things. So, penicillin was originally discovered, because the researcher was trying to do some research and left a petri dish, I think over for a couple of days. And then mold started growing. And then the bacteria cultures actually started dying around the mold. And he's like, wow, like that mold might be useful in pharmaceuticals one day to kill bacteria. The same way, Viagra was discovered, right?

Farbod: Heart medicine.

Daniel: Yeah, it was originally being studied as a heart medicine. And then one of the ones that's really, really interesting to me, is the microwave that appliance that all of us have in our kitchens these days, was actually originally discovered as, or it was originally intended as a way of transmitting wireless power. So, this researcher was trying to figure out how to shoot wireless power from one end of the room to the other, trying to be like the, you know, 100-year-old precursors to the Internet of Things, devices that we have today, using this microwave trying to send wireless power, he realized that I think he had like a chocolate bar in the desk, and the chocolate bar started to melt. And he's like, Wow, maybe this is a great way of maybe not a trans transmitting electrical energy, right. But maybe we can use it as a way to transmit thermal energy. All that being said, right, so we've got this team that accidentally discovered this. I think that one day, it's possible that we put PPM up there in the ranks of like these accidental discoveries with penicillin, Viagra with microwaves, because, and we'll talk about the application that Marc D’Elia ended up figuring out for this material and corrosion protection. I think it's really, really interesting. And it addresses a lot of the pain points that exist right now in the corrosion protection industry as a whole.

Farbod: And, you know, you're talking about the scale of this thing like penicillin. So, I think some context is required as to why you think that and know before we dive into the details of Marc's application to do this corrosion protective coating. Let's talk about the problem of corrosion. Yeah, exactly. I think it's such a passive like, Dude, you and I, we took like material science courses and stuff. Like we were engineering students for a couple years first, I didn't know corrosion was even that big of a problem until Dr. Noson, started reading the stats for us. And I think we both worked on a senior design project for corrosion, protection, robots to corrosion detection robots, and it became like, like, etched into my brain, because I was pitching it so many times as background. But the short takeaway is that imagine pretty much three and a half percent of the global GDP goes into corrosion solutions or addressing corrosion to some extent. And that's about 4 trillion US dollars a year. That's how big of a problem it is. And a lot of times, it's just like, you're not even preventing it. You're just keeping up with it.

Daniel: Yeah. Yeah, that's what I was gonna say is skyscrapers, bridges, ships, airplanes, cars, pretty much everything that humans make, sooner or later starts to decay. And a big part of that is corrosion. We're spending $4 trillion a year trying to fix this, and we still can't keep up with it. So that that shows how important the problem is that shows how big of a problem it is that we can throw $4 trillion a year at it. And we're still not keeping up, we still haven't found a truly like silver bullet effective method of protecting metals with coatings that keep them from corroding with detecting where defects are in that corrosion protection and preventing further corrosion from happening. I think there are a couple of different pain points, which include coding, which include detecting, and then also repairing defects, all three of those, I would consider, really three big pain points in the corrosion space, that are all addressed accidentally, by this PPM coating.

Farbod: And the last two, the detection and doing something about it was the one that you know, the projects that we did, we're trying to address back in college detection is difficult because in a lot of cases, you literally just need a human being to go look at it, like physically look at the sites that are supposed to be corroded and tell you if it's bad, how bad is it and what solution to take, right? There's just no way around it.

Daniel: In the case of detection, right, just to show how much of a problem it is we were the you know, Department of Defense willing to sponsor teams of engineers to study these hundreds of 1000s of dollars every year to try and study this and figure out how can we make robots that accurately detect where there are defects? So, we know how and where and when to fix them. The fact that this is such a big problem that we're throwing hundreds of 1000s of dollars at it every year. And then again, well, I hate to keep, like alluding to the superpower that these this PPM coding has the fact that this PPM coating makes defect detection really, really easy, I think, you know, let's just dive into it now, because I like putting it out. But I think I think it's super interesting, right. So, this poly phenylene methylene PPM coating, what they do is they using it as a corrosion protection. They mix it with paint, and they spray it as a liquid, and then it eventually cures and becomes solid. That helps with the first of the three pain points, which was coating, right, you're actually able to get a thinner coating with the PPM that's more durable, lasts longer, and it's easier to do. So, lots of epoxy coatings that require multiple layers, they're really heavy, they're really, really expensive, because you're using a lot of material to coat something. This PPM coating is a lot thinner, a lot lighter, a lot less expensive, a lot less material. And it still performs as good or better than the industry standard epoxy coatings that we use on a lot of metal pipes.

Farbod: And by a lot thinner. Again, just for the scale, apparently a 1/10 layer, the thickness in comparison to the epoxy one results in the exact same durability. So that is I mean, again, think about material cost, think about weight. This is able to do 10 times more cover 10 times more surface than we currently can and to cozy, right and the labor to cope.

Daniel: Yeah, yeah. So that's again, that was our first of three-pain points coding. Let's talk about detection. How does PPM help us with detection? I think this one, this is the one that started me saying like, wow, this, this sounds like siding. It sounds like a comic book that I was reading a while ago with like a superhero that had this like, super strength, it was super thin. And also, he can glow in the dark, right? That's about wait, there's more I can do, right? Pretty much.

Farbod: So, you got this coating that like we talked about. It's it has fluorescence, but it does not shine, it does not fluoresce where there are cracks and pits, which is typically the sites where you have degradation caused by corrosion. And again, we talked about it and if you have a human inspecting these, they kind of have to like go up close inspect them one by one, which can be very painful. Now this even if you still have a human doing it, this can give you a little bit of insight of like, okay, this is probably where I should hone in on my focus. Or if you have a robotic solution, this makes the problem like 10 times easier, because now you know exactly where to localize and where to inspect them or do whatever.

Daniel: I mean, that's part of the some of the projects we worked on in the past for robotic corrosion detection inside pipes was you were you were trying to use cameras to try and sense and detect the size and shape of different potential defects. I was trying to use electricity to try and characterize where there may or may not be defects. All this to say its people spend a lot of time and money trying to figure out where defects are trying to first detect them and then localize them to a specific area. And it turns out, you know, with this PPM coding, all you need is a UV light. And using this UV light, you can see where there are discontinuities in the coating and pinpoint exactly where defects are and exactly where repairs need to be made. And I think that's really, really interesting, because a lot of the times the coating may look uniform, even though there's a defect underneath if you're using your traditional epoxy paint. And that's why we needed to use these things like specialized cameras that are up close, or using electricity to try and characterize where there are defects in the metal. Yeah, but this, this allows you to do it non-invasively without scratching the coding, but you're able to pinpoint exactly where even though it may not be visible to the Blind Eye exactly where a defect might be in the coding.

Farbod: Right. So, what I was gonna say is even with all these solutions, I don't know how your solution panned out, actually. But with ours, when we're using the camera, it was possible to get a false positive because you there's so many factors, there's lighting going to take into account the color of the coating, so many things that can lead to like inaccurate results, and we try to filter as much as possible. But now that you have this, like very distinct, shining with fluorescence and not shining, it makes that process so much easier.

Daniel: And I 100% agree with what you're saying there's there may not be specificity of this indicator, right of UV light cracking, maybe 10% of the time, it's a false positive and find something that's not a defect because the fluorescence didn't work the way it's supposed to due to inconsistent sees in the coding or something like that. But it's a perfect opportunity to use this as a sort of sensor fusion alongside the rest of these robotic solutions that are using cameras that are using, you know, resistance monitoring, ultrasound, all these, you know, there's a full sensor array, this is something that I feel like it'd be a very high signal to noise ratio version to blend into these sensor arrays to try and get really, really accurate with where defects are detected. And I also liked the possibility for this to be used just by human operators walking around with a UV light sweeping for very, very large structures to try and detect where there might be major defects, not just minor ones that we need to monitor and maybe fix in the future, you can find major defects on structures like bridges and things like that, where it would be hard otherwise, to send a robot there to try and monitor it.

Farbod: I mean, we talked about filtering, and at least on our side, where we're doing image processing, so there's an algorithm taking care of that. But this can be thought of as like a built-in type of filtering, that's physical and it's agnostic to the system

Daniel: You’re using to in the ferrousing phenomenon, right? You're, you're measuring the UV light ferrousing, right, not trying to play around with what color something is or what the lighting is outside, or, you know, whether there's inconsistencies in the coding, I think it's really, really interesting. And that addresses pain. Point number two for us. So, we talked about pain. Point number one is coding pain. Point number two is detection. The third pain point in corrosion protection, that Farbod and I, wherever it now is reparation, repairing these defects. And, you know, this superhero PPM strikes again, with another superpower. It's also self-healing, which is insane to me, probably the

Farbod: most interesting, out of the three, for me, at least. So, they talk about the researchers in the article, they talk about how self-healing polymers are all the craze right now, right? I don't know if you know this, but like, the new electric BMW models have this, what I think is a very stupid design for a grill. But it has, it has a

Farbod: Yeah, I mean, I feel very strongly about my car designs, and they just, I'm not going to go on this tangent anyways, they have this plastic grille. And what's cool about it is, you know, like, it's definitely gonna get debris hit on it, it's probably over its lifetime gonna have some scratches that come up. This polymer when exposed to high heat, let's say from boiling water can just heal itself and those scratches will go away. And in a different light, like looking at the old world, I was scrolling through Twitter, and I saw this thread about how Roman concrete was different than modern day. It's pretty cool, man. For the folks that don't know, the old mixture that the Romans were using, they would incorporate limestone. So as cracks inevitably, inevitably happened in the concrete, water could flow through react with the lime, and then create calcium, calcium something.

Daniel: Yeah, it basically reclassify. So, like the same house, you see when you, you know, stuff turns white in your shower because of the hard water. That's because there's a lot of calcium, a lot of minerals in the water. They basically built these minerals into their concrete knowing that if this cracked, right, these minerals could again mix in with the water and then cause calcium deposits to happen and fill those cracks. You know, 1000s of years old, we had self-healing concrete from the Romans. Pretty sweet. And I honestly think that this PPM coating is a lot more like the Roman concrete than it is like our state-of-the-art BMW front facia grill, right because the front facia grill on the BMW requires an external stimulus requires an external intervention with you pouring a pot of hot boiling water on it to fix it, which that alone is really cool. But I honestly admire even more what the Roman concrete was able to do because at ambient conditions without anyone intervening, it was it's able to repair minor defects in itself just by failing. And that's something that happens here with this PPM coding. So basically, the long and short of it is this PPM coding has some chemicals built into it that when the coating fractures, right when the coating cracks when there's a defect and it comes into contact with the raw moto raw metal, it reacts with that metal and heats up enough so that it starts to heat up the local area around the defect, and it melts the PPM coating, and then it really cools and hardens itself to cover that patch. And you know, the way I like to think of it is very similarly to that Roman concrete right where there was a crack, there was a chemical reaction that happened which caused new material to deposit there and harden and fill the crack. I don't think this is going to repair major defects like someone you know, taking a major chip off of the PPM coating, but for a lot of the minor cracks and defects that happened from things like settling that happened from things like weathering and erosion over time. I think that this can help increase not just the longevity of the coding, right, it's able to last a lot longer. But there's also a lot lower risk and having to try and detect the minor defects because they're healing themselves. So, you can focus again, on the detection aspect, you can focus on major defects, knowing that the minor defects are largely going to be healing themselves. So, you don't need to spend a lot of time fixing things that look tiny now thinking that they may grow into a major defect in the future.

Farbod: You’re absolutely right. And I think it's worth noting that the analogy with the Roman concrete doesn't even stop there. You know, we talked about the three main issues that current protective solutions for corrosion have, there's a vote wait, there's more Yeah, moment with PPM here. And that's environmental friendliness. One of the ones that I want to touch on that relates to the concrete is that they talked about how polymers that self here right and self-heal right now have like extra chemical additives, and these can leach out and go into our oceans and environment. Obviously, that's not great. They also note that, you know, you're never going to have a synthetic solution that's gonna be completely perfect, but you can design it to be as good as possible. PPM does not have any other extra chemical additives that can leach it is just innate to itself that it can do the self-healing thing, much like the limestone being incorporated and calcifying over time,

Daniel: Going further down your, your rabbit hole here with environmental friendliness, I said this is almost qualifying as pain point number four, which is the fact that we have a hard Trump hard time disposing of current coding. So, say, you know, I, I coat this pipe with epoxy coating, because I want it to be really protected from corrosion. Over time, it starts to break down, I scrape off all this coating. And it's annoying because I've got 10 times more coating than I would have I'd use ppm in the first point. But you know, by the end, I've got this huge dumpster full of this epoxy coating.

Farbod: What do you do with it?

Daniel: I've got no way to dispose of it. Similar polymers that are used for coding today, right, these epoxy coating, stuff like that. There's only two major ways of dispersion what disposal one throwing it into a landfill what you're saying that that can leach into our water supply leach into the ground. Or we can incinerate them. So, we can burn them and put those chemicals into the atmosphere and breathe it in those sounds like a great answer to either drink and E or to breathe. These chemicals that these harsh chemicals that we're using to coat things. The PPM it's what 95% recyclable?

Farbod: Yep, and we've talked about recycling in the past with polymers, right? The issue has always been that every time you recycle, you degrade material properties. It's 95% recyclable without losing any of the special or functional properties

Daniel: I think they said they can do it up to six times, right, they're able to, to reuse the same material again and again and again, with minimal loss, and then the properties and then the function. Again, like, I keep going back to the scenario, this sounds like

Farbod: We're fangirling but there's a reason like, you know, it's like

Daniel: It's super thin, it's super strong glows in the dark, it can heal itself, and then it can rejuvenate. It can regenerate itself. It's got multiple lives. This sounds like things that I would have, you know, properties that I would have attributed to my favorite superhero as a kid. Like, this is the super new superhero incursion coatings.

Farbod: Marvel should just give up we have their new hero; we know what phase I don't even know what phase are on phase four. Phase Five is gonna look like and it's gonna be all about PPM.

Daniel: Yeah. I mean, they should talk to this team from ETH Zurich and see if they can borrow some, you know, maybe the origin story is some guy falls into a vat PPM and turns into super PPM man, I don't know.

Farbod: PPM man. Yeah, that works.

Daniel: It is super interesting to me. And again, I love hearing about these material properties that kind of feel like they're on the boundary of what we know to be real, like self-healing, like going in the dark, like being truly recyclable. And, you know, showing super strength thanks to the nanotechnology involved. It to me, brings me a lot of joy makes me feel like I'm a kid again learning about superheroes and their different powers. But at the same time, it scratches this itch to me, which is I'm a huge material science geek. I love that couldn't tell honestly, I love that them being able to innovate at the forefront of materials, right trying to generate new material properties, has directly trickled down into real world applications that can solve real world problems. And in this case, it's a $4 trillion a year problem. It's a big deal. And it's something that again, you said you can't tell, but we're really excited about it.

Farbod: But that's, that brings up a good question. So, like they made this discovery. It's great. There's a big problem, it can address it. So, what the so what here is that they actually the team has a patent pending, which is great. And as of now they're looking for industry partners so that they can commercialize this thing. Their eyes seem to be set on getting this thing out to the commercial partners and deploying it in the real world. They said that there's formulations that they gotta get right once they found the right partner, but they're taking the steps. Again, not keep this in a laboratory, but make sure it's being used and utilizing its full effects in our day to day lives.

Daniel: I mean, that is a testament to the leadership team that's involved in this laboratory, Markus Niederberger and Walter Caseri, Walter Khesari, the fact that they've had PhD students and postdoc researchers working on making this thing useful in the real world for 10 years, and they finally cracked it, they found something that works, I appreciate that they're, they're not doing this thing that I usually have a pet peeve with academia, which is like, wow, we discovered this cool thing, we write a paper about it, and we put it on the shelf, because we there's no immediately present real application for it, the fact that they were able to work on it, and this team, you know, big kudos to Marco D’Elia, for figuring out a way to use this in corrosion protection. Absolutely. I would love to see this get commercialized, I would love to see this be, you know, a really competitive alternative to epoxy coatings and all these other things that we've got us state of the art today. And we'll see superhero PPM coatings out in the real world.

Farbod: I'm looking forward to that. But before we wrap up, I think we got to give a quick rundown and TLDR, Eli five, what we just talked about, so I'm gonna give it a go. We have this huge problem in the world, about three and a half percent of the global GDP, about $4 trillion is spent every year to address corrosion. And that doesn't even mean like solving it. It's just trying to keep up with it. Big, big reason that that's the reason that we're spending so much money is because of the coatings that we use the coatings, they're very thick, because they have to be or else, they can't actually do their job well. They, they don't do a good job of showing us where the actual corrosion is. And even if we find it, fixing, it is not very easy. And after we're done with the coatings, getting rid of it causes either pollution or lungs, or pollution to our environment. So, these folks, they discovered this new polymer by accident, it's called PPM. It has natural fluorescence. And the reason that that's important in context of corrosion is where there are cracks where there are holes, it will not fluoresce. That's the right word. Right? Yes. Okay, great. And that'll make it easier for people to see, in addition to that, a layer that's about 1/10 of the thickness of our current coatings will result in the exact same durability, which means, you know, it's easier to deploy. And it's recyclable. It's self-healing, it reacts with the metal underneath it to some extent to make sure that, you know, as it degrades, it's trying to keep up with it. And in this self, I mean, the environmental friendliness aspect, you can reuse up to 95% of it six times without losing any of its core functional properties. Is a good summary, is that wrapping up?

Daniel: That's like, that's the superhero story. I want to be reading in a comic book at some point.

Farbod: Maybe that's something we gotta start taking up. We love materials. We talk them all about a lot about them a lot. We got to start writing comics, but comic books about them. Maybe the NextByte universe that doesn't have doesn't roll off the tongue. Right.

Daniel: We'll work on it. We'll work on it.

Farbod: Alright, that's the episode. Everyone, Thank you so much for listening. Did we trend anywhere last week? I did not look it up for the check. All right, well, we'll let you know if we missed it this episode, but thank you. Thank you, guys, for listening, and we'll catch you the next one.

Daniel: Yep, Peace. Out.

-----

That's all for today The NextByte Podcast is produced by Wevolver, and to learn more about the topics with discussed today visit Wevolver.com.

If you enjoyed this episode, please review and subscribe, via Apple podcasts Spotify or one of your favorite platforms. I'm Farbod and I'm Daniel. Thank you for listening and we'll see you in the next episode.