How To Run An Effective And Successful In-House Maintenance System

The digital collection of maintenance data — a huge volume of data — is, along with advanced analytic capabilities, the basis for establishing a successful predictive maintenance system. Big Data, coming from IIoT devices and into CMMS software, is changing the way we do industrial maintenance.

Getting maintenance right is a tough challenge for any business, regardless of industry or size. It’s clearly important to do so since there are multiple benefits to having a good maintenance regime. Better asset retention and fewer machinery and process breakdowns help improve productivity, worker safety, and — of course — the financial bottom line.

Predictive maintenance (PdM) is the quintessential proactive maintenance regime for the modern facility. It is (or at least should be) the polar opposite of reactive maintenance — maintenance that, as its name denotes, only kicks in when things break down.

Predictive maintenance (EXTERNAL) has been defined as maintenance that uses data science, invariably based on artificial intelligence (AI), to provide analytics that can estimate or predict when machinery or equipment may fail. This enables maintenance measures to be taken prior to point of failure.

Predictive maintenance achieves this by using an underlying architecture that comprises data sets of considerable size, including their acquisition, storage, and transformation. Condition monitoring, evaluations of asset health, and prognostics are other important facets of the predictive maintenance model.

Fundamentally, operational data (EXTERNAL) will determine when an asset requires maintenance in advance and, ideally, with the least interference to production. Little wonder that it remains popular, with the predictive maintenance (EXTERNAL) market set to grow to $25 billion by 2025.

Now, this is all very well and very good — but how can one run an effective in-house predictive maintenance system using all that data? This article will answer just that question.

Big data in all its glory

Data has become exponentially more immense and complex in recent years. Big Data is the net result of this huge growth in data. The upside is that businesses have more access to machinery-related data than ever before. The downside is that all this data has become increasingly difficult to store and analyze.

This tsunami of data, collectively known as Big Data, means that facilities can make decisions based on hard, technical evidence, rather than intuition or endless calculations. But sense needs to be made of all this data, which is where the ‘3 Vs’ of data (GOOD) come into play.

Volume is an obvious way to define data. Currently, more than 2.5 quintillion bytes of data are produced every single day. That equates to 18 zeros. Big Data clearly needs huge volumes of data, with AI-driven data-processing capabilities to match. That is why it didn’t exist 20 years ago.

Velocity is also key to Big Data, since it requires a significant speed at which data can be generated, processed, and disseminated. High-speed data processing requires algorithmic tools and advanced analytics that make sense of the data in fractions of milliseconds.

Variety is also key to Big Data. Traditional data that once comprised the bulk of what businesses generated (such as spreadsheets and text) is relatively easy to store. Far more difficult are the data-intense, varied forms of unstructured data, such as video and audio, which are important in predictive maintenance. For example, the continuous heat imaging generated by a machine’s sensor is dense in data.

Predictive maintenance is clearly heavily dependent on data-gathering and analysis in all its ‘3Vs’ glory. An excellent, fairly inexpensive way of making sense of all that data is to use an AI-enhanced computerized maintenance management system (CMMS) software.

A CMMS can do everything from gathering and analyzing huge amounts of asset-related data, to managing maintenance schedules. A sound CMMS (EXTERNAL) can achieve much, including:

- reactive maintenance reduced by as much as 73.2%;

- downtime reduced by up to 32%

- productivity increased by 28%; and

- cost of components/parts reduced by 23%.

Together with a viable CMMS, predictive maintenance can achieve its core function: prognostic analytics (EXTERNAL). Machine learning (ML) models can identify the current ‘health’ of machinery and system processes so that machinery and system failures can be averted. And at the center of it all is data — a lot of data.

The importance of multi-channel asset data

For maintenance, it’s clear that one needs a large volume of asset information in order to predict asset-degradation events successfully. This is best achieved using a multitude of input channels — one of the ‘3Vs of data’ outlined above was variety.

Machines and devices interconnected via the Internet of Things (IoT) are an important channel for disparate sources of data. It explains why IoT-connected devices (EXTERNAL) are projected to increase to 43 billion by 2023. IoT sensors, often in their hundreds or even thousands throughout a facility, can gather data from machines that have been installed or retrofitted for that purpose.

There is a wide variety of condition-monitoring techniques (EXTERNAL) that can stream ‘smart’ data into a facility’s predictive maintenance system, including those for:

- acoustic analysis

- electromagnetic measurements

- laser interferometry

- motor circuit analysis

- oil/lubrication analysis

- radiography/radiation analysis

- thermography readings

- ultrasonic analysis

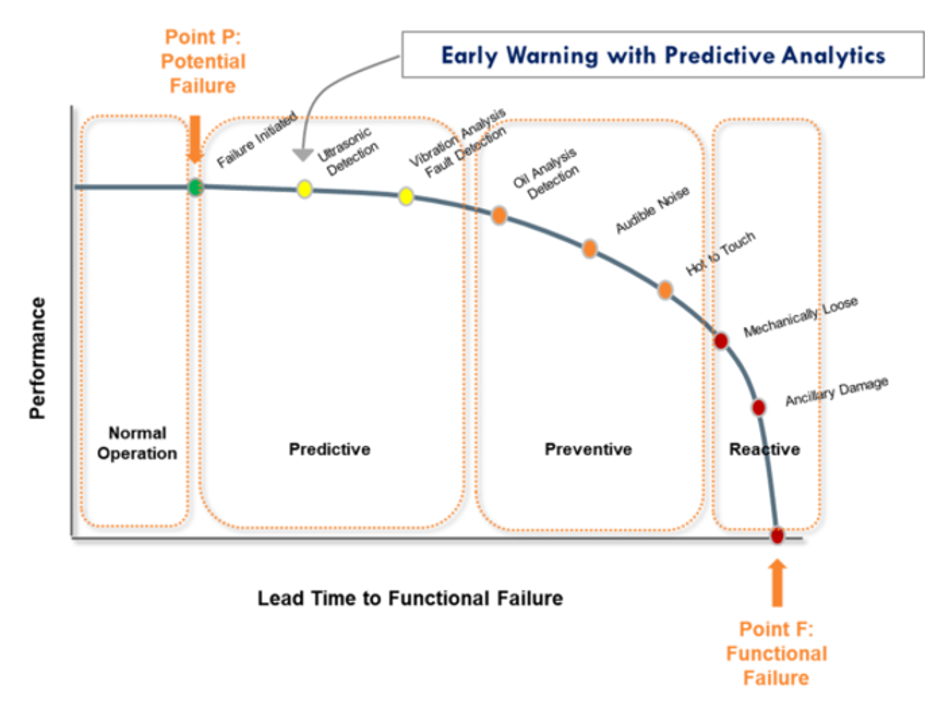

Ultimately, all the acquired and ‘crunched’ data must assist in ensuring a healthy system. This can be hypothesized by the use of a potential-functional failure curve (the P-F Curve), where the aim is to detect fault before failure occurs, i.e. a machine or process breaks down. The graph below illustrates how much more effective predictive maintenance is in preventing failure compared to other maintenance types:

Asset information that counts

Too much data is not a good thing, though. Or rather, data that doesn’t add value or lies dormant is especially problematic. ‘Data dumping’ in the context of maintenance cannot be ignored. This can result in large reservoirs of dumped data on a company’s servers or in the cloud, referred to as ‘data graveyards (EXTERNAL)’.

Excessive, unused data can be highly problematic (not to mention costly) in terms of both storage infrastructure and IT maintenance. The problem for industrial maintenance is that all this poor-quality data can dilute real-time data regarding the condition of machinery and process systems.

AI and ML may be very smart, but they still need good-quality data to be able to make decisive and precise diagnostic and prognostic analyses. The simple principle of GIGO applies here — garbage in, garbage out.

A CMMS database (EXTERNAL) can greatly enhance the quality of data that is analyzed for predictive maintenance purposes. It achieves this by sorting through the data streaming in, and ordering it according to different functions, such as:

Asset-related management

- Asset registry and availability

- Condition monitoring statistics

- Location and position of machinery

- Manufacturer details, such as model, serial number, and equipment class

- Reserve materials and equipment

Resource and labor management:

- Performance and downtime statistics

- Work order management

Industry 4.0 and maximizing predictive maintenance

Industry 4.0 has become fully admitted to the engineering verbiage. First introduced in Germany in 2011, Industry 4.0 is at the heart of the ‘Fourth Industrial Revolution,’ with its focus on ‘smart manufacturing’ predicated on interconnected machinery and processes. Big Data is clearly central to an Industry 4.0 facility.

However, it’s also becoming somewhat overused. Why? Because many companies, including top manufacturing companies, continue to lag in their uptake of this ‘revolution,’ which is already over a decade old. Too many companies are struggling to achieve the digital transformation needed. This was the principal finding of a 2022 survey (EXTERNAL) of 400 manufacturing executives in the United States and the United Kingdom.

A Swedish survey (EXTERNAL) of nine companies that provide overall equipment effectiveness (OEE) solutions in the Swedish and European markets was equally sobering. These solutions providers complained that most manufacturers continued to be highly conservative in their culture with a ‘we do as we have always done’ philosophy.

These companies also find that manufacturers are too stuck on the costs of digital transformation, and not its potential value creation.

Another important challenge for any Industry 4.0 regime is connectivity. A hyper-interconnected smart facility depends heavily on high-speed, low-latency connectivity. This affects predictive maintenance as well, with its reliance on 24/7, split-second data acquisition, formulation, and distribution.

This is especially concerning in critical facilities (EXTERNAL), such as power generation plants or healthcare facilities. As Flavio Caracas, Senior Director for Nokia’s Network Infrastructure Group puts it: “When there is a problem in these networks, the effect can go beyond the walls of the company into potentially life-threatening and macro-economic events.”

Predictive maintenance works hand-in-hand with Industry 4.0 and ‘smart factory’ principles, given that the latter concepts are themselves immersed in smart data. Modern Maintenance and Repair Operations (MROs) (BAD) are reliant on data-rich analytics. However, these maintenance objectives can only be objective if the ‘smart facility’ is indeed smart.

Think even bigger, perhaps?

Your organization may be sophisticated (or bold) enough to want to take maintenance beyond the predictive to the next level: the prescriptive. Essentially, prescriptive maintenance (RxM) offers solutions to diagnostic and prognostic data outcomes.

It may take predictive maintenance ‘to the next level,’ but prescriptive maintenance still needs predictive inputs as its foundation. It has been suggested that “prescriptive maintenance really means ‘predictive maintenance based on prescriptive analytics (EXTERNAL)’. It could also be considered predictive maintenance with recommended actions attached.

There is no denying the value of prescriptive maintenance. Being able to understand the ‘why’ behind a failure (EXTERNAL) is hugely beneficial, in that it ensures a truly proactive, solutions-driven response.

The benefits of prescriptive maintenance include maximizing the yield and longevity of assets, thereby extending service cycles, with resultant cost efficiencies and savings.

The use of industrial IoT (IIoT) in tandem with data-collecting technology — such as drones — is an example of solutions-focused maintenance. Drones can gather visual data at remote locations, such as substations, or even assist in discerning the needed maintenance of aging housing stock in a heavily built-up city such as Hong Kong (EXTERNAL).

In conclusion, there is no denying that data — or, more specifically, Big Data — will increasingly shape maintenance. It is already changing the field almost entirely in both focus and required competencies.

Predictive maintenance makes excellent use of asset-related data, both historical and real-time, allowing intelligent maintenance decisions to be made. This can be richly rewarding and valuable in terms of both asset management and resource and labor management.

Going forward, Industry 4.0 and the ongoing maturation of data-led maintenance should make prescriptive maintenance increasingly popular, even inevitable, albeit invariably on a foundation of predictive maintenance.