Ensuring EMC Through A Validation Ecosystem: Anechoic Chambers, Motor Bench, and Advanced Simulation

ROHM's R&D facilities integrate EMC testing, motor bench evaluation, and advanced simulation to tackle electromagnetic noise, efficiency, and thermal challenges. Together, they create a preventive validation ecosystem that accelerates development and ensures reliable, compliant electronic systems.

Introduction

The growing complexity of electronic systems is reshaping how engineers ensure reliability and compliance. Faster switching speeds and denser integration have made electromagnetic compatibility (EMC) one of the most critical design concerns, as noise issues discovered late in development often force costly redesigns. In addition, system-level demands, such as energy efficiency and accurate prediction of thermal behavior, are linked to EMC performance.

To address these interrelated challenges, ROHM has established an end-to-end validation ecosystem. By combining accredited EMC measurement chambers, advanced motor bench systems, and web-based simulation tools, ROHM enables customers worldwide to implement effective countermeasures early, achieving greater design confidence, compliance, and efficiency.

EMC Validation with In-House Anechoic Chambers

Electromagnetic noise is one of the most pervasive risks in modern electronics. When left unchecked, it can lead to malfunction, system instability, and even regulatory non-compliance. For IC designers and system engineers, tackling noise at an early stage is critical.

To support this, ROHM operates its own accredited EMC measurement facilities. Located at the Yokohama Technology Center, Japan, these facilities include:

3-meter anechoic chamber for precision emissions measurements.

Automotive EMC chamber, which replicates real vehicle wiring harnesses and mounting conditions to test immunity and emissions in application-relevant environments.

This in-house capability works strongly to the customer’s advantage. With ROHM’s process, EMC countermeasures are designed during the IC development stage, allowing the customer to proceed with their designs with greater confidence. This significantly reduces the risk of late-stage redesigns and is one of the key advantages of ROHM’s robust EMC validation ecosystem.

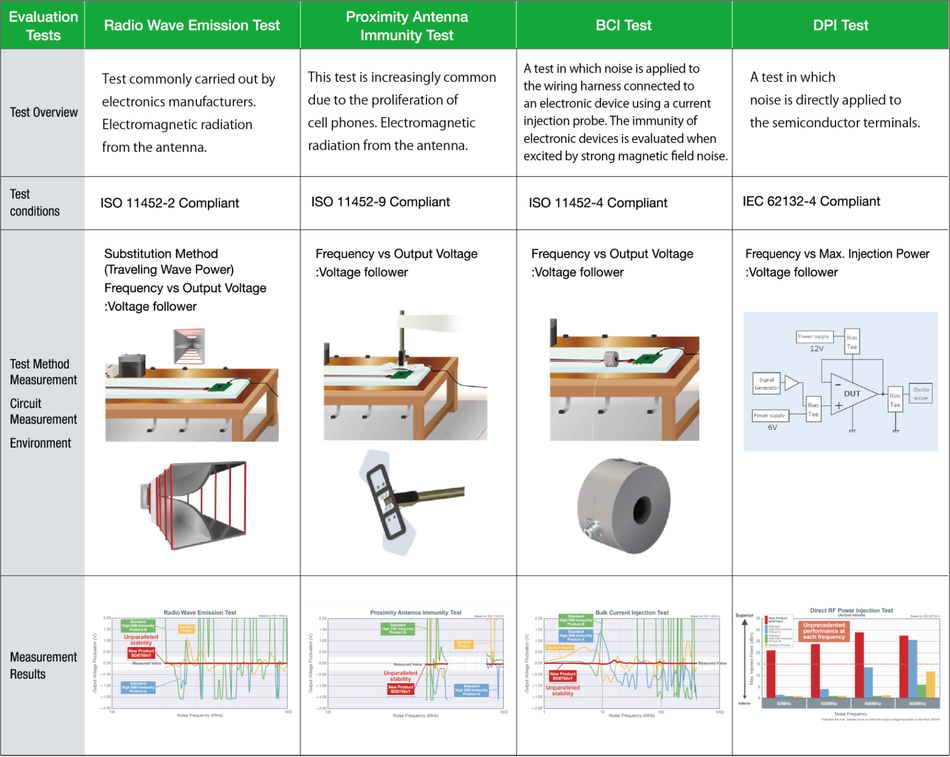

Table 1: Key EMC tests at ROHM

A notable example is the development of ROHM’s EMARMOUR™ operational amplifiers, which achieved industry-leading immunity to electromagnetic interference (EMI). This success came from iterative testing in the anechoic chambers, where circuit proposals were measured, refined, and validated until breakthrough performance was achieved.

Motor Bench Evaluation for Efficiency Testing

While EMC focuses on noise and compliance, efficiency must also be evaluated for a reliable system design. In electric vehicles (EVs) and industrial drives, energy savings translate directly into reduced operating costs, longer range, and higher overall performance. Yet validating efficiency is complex because it requires testing not just individual devices, but entire drive systems.

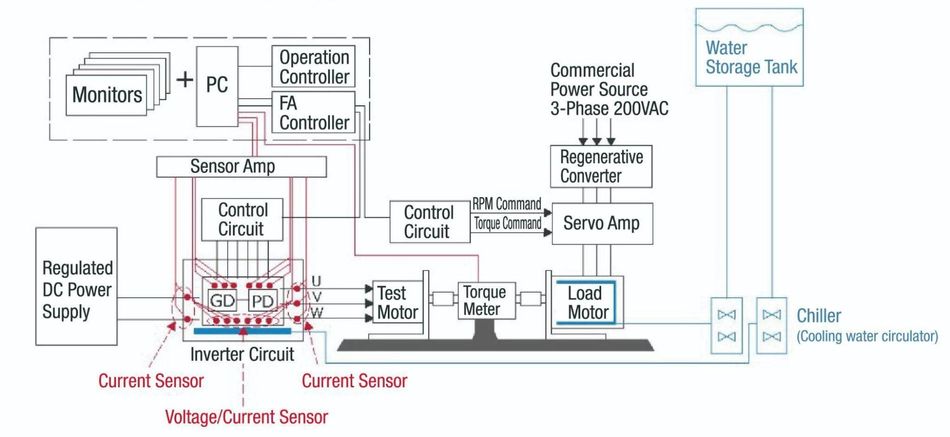

ROHM addresses this challenge with its motor bench evaluation environment, which reproduces real-world conditions for motors, gate drivers, and power devices. The setup includes a test motor and load motor configuration, regenerative converters, precision current and voltage sensors, and a dedicated control PC. This allows engineers to monitor efficiency and potential behavior under real operating conditions across a wide range of varying torque and rotational speed sequences.

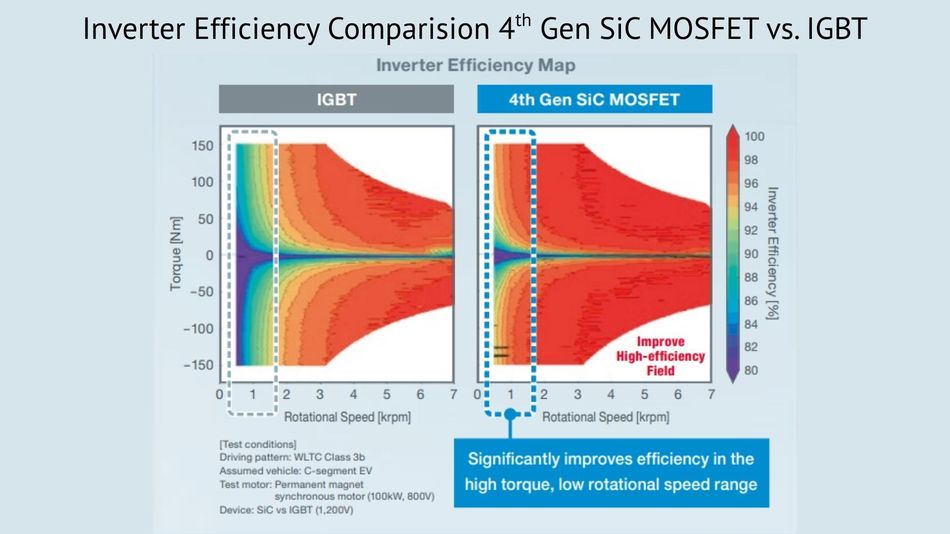

In comparative tests under Worldwide Harmonized Light Vehicle Test Cycle (WLTC) Class 3b conditions, inverters equipped with ROHM’s 4th Generation SiC MOSFETs achieved up to 10% lower electricity consumption compared to those using conventional IGBTs. This confirms that high-efficiency operation can be achieved while ensuring performance gains do not introduce excessive noise.

By enabling these detailed system-level measurements, customers gain early insight into energy savings, and overall reliability before moving to costly prototyping or large-scale production.

Simulation Tools for Virtual Validation

Even with advanced EMC facilities and motor bench testing, designers often need to validate performance much earlier in the development cycle. Prototyping is expensive, and datasheets alone cannot capture the complex thermal and electrical interactions that occur in real-world systems.

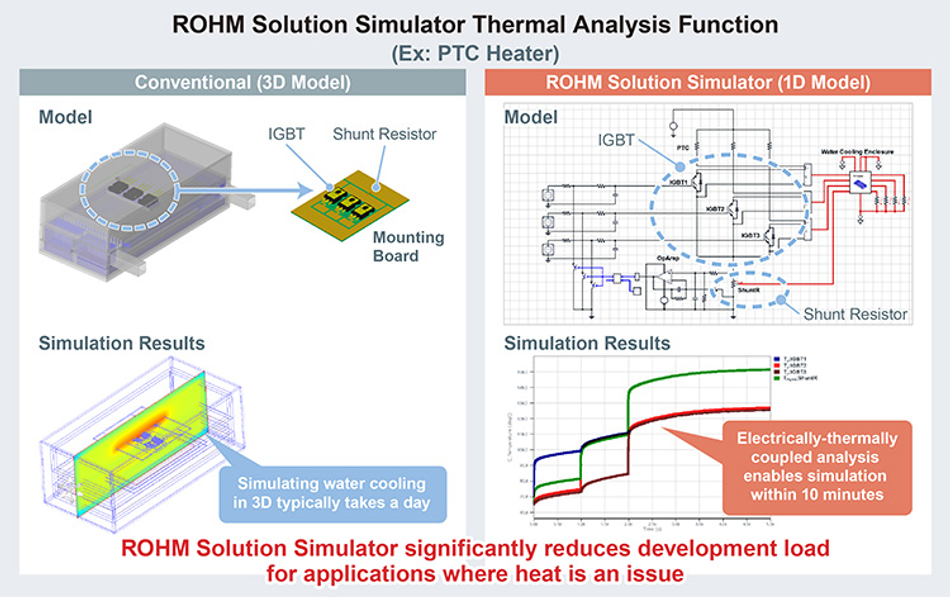

To help with this, ROHM offers the ROHM Solution Simulator, a free, web-based tool that enables engineers to evaluate devices and circuits under realistic application conditions. This tool is unique in the way it allows not only ICs but also entire circuits including discrete components such as transistors, diodes, resistors, and LEDs, and it also supports thermal design.

Another key feature is its electrical-thermal coupled analysis. What once required a full day of modelling and computation can now be completed in under ten minutes, making it approximately 100 times faster than conventional methods. Designers can quickly examine junction temperatures, pin-level heating, and thermal interference between components, gaining insights before hardware is even built.

The simulator also fits seamlessly into existing workflows. Engineers can select a solution circuit, choose specific ROHM devices, run simulations, and even order samples directly. For more advanced system-level validation, results can be exported into the Siemens EDA PartQuest environment.

Strengthening Competitiveness Through Validation

When viewed together, ROHM’s validation facilities form a comprehensive ecosystem. Each contributes to a different but equally critical dimension of design reliability:

State-of-the-art anechoic chambers ensure compliance with global EMC standards and protect against system malfunctions caused by noise.

Motor bench testing validates real-world efficiency and performance of drive systems in automotive and industrial applications.

Simulation tools accelerate development of the entire electrical circuit by identifying thermal, electrical, and heat-related issues before hardware prototyping.

For customers, the combined benefits are clear: development cycles become shorter, reducing time-to-market. Risk is lowered because potential issues are identified earlier, preventing costly redesigns. Compliance confidence is strengthened across international markets, ensuring smoother certification processes. And system-level performance is optimized, translating into energy savings, safety, and reliability.

Comprehensive design measures significantly enhance product reliability and safety while meeting customer expectations. This approach delivers exceptional value through both technical expertise and support systems, strengthening competitiveness in the global market.

ROHM’s Application and Technical Solution Center in Europe

While the tools and facilities discussed in this article are based at ROHM’s R&D center in Japan, customers in Europe also benefit from local expertise through the European Application and Technical Solution Center (ATSC) in Willich, Germany. To support users in their development efforts, the EU support team offers services that contribute to the quality of the customer's end product. The facilities in Germany are not only meant for low-voltage IC products: Through a modern lab ROHM also provides support for power devices (IGBTs, SiC MOSFETs) with voltage classes up to 2 kV since 2018.

The ATSC focuses on supporting engineers during their design-in phase, providing application boards, reference designs, and hands-on technical collaboration. By working closely with local development teams, the ATSC ensures that European customers receive support for integrating ROHM’s analog ICs, power devices, and system solutions. This way, ROHM combines cutting-edge R&D infrastructure with regional engineering support, delivering a balanced approach that strengthens customer competitiveness worldwide.

Conclusion

EMI, energy efficiency, and thermal management are often invisible yet decisive for reliable, compliant electronics. If overlooked, they can cause redesigns, certification delays, and performance losses.

ROHM’s R&D facilities employ anechoic chambers, motor bench evaluation, and simulation tools as part of a preventive validation ecosystem that helps customers detect issues early, apply effective countermeasures, and deliver designs that are globally compliant, efficient, safe, and reliable.

Explore further: Endless Struggle Against Invisible Noise | ROHM