Custom Cable Assemblies for Specialized Applications

How Molex and Sager Electronics turn complex interconnect requirements into streamlined, production-ready cable solutions.

Executive Summary

Connectivity requirements in modern systems are getting more specialized, driven by the need for higher speeds, increasing power demands, and mechanical constraints. Millions of off-the-shelf cable assemblies and interconnects are available in the market, but they are suitable only for prototyping and standard use cases. More complex applications require specific configurations to ensure they align with the system-level electrical, mechanical, and environmental needs.

The purpose of this white paper is to explain how Molex and Sager Electronics come together to offer a solution that streamlines the process of developing a custom cable assembly, supported by digital tools such as the Molex Custom Cable Creator. It presents an overview of the customization possibilities and explains how users can easily browse, configure, obtain quotes, and order samples for all their custom cable needs.

Introduction

Manufacturers are constantly trying to bring more features to their products. As electronic systems become more complex, engineers must ensure performance, reliability, and power efficiency remain unaffected and, if possible, improve with each generation.

The role of cable assemblies is shifting from acting as simple interconnects to being critical components that directly influence the system’s signal integrity, thermal behavior, and environmental resistance. This shift has given rise to the demand for interconnects that accurately align with the product’s electrical and mechanical requirements.

Challenges with Off-the-Shelf Cable Assemblies

Standard off-the-shelf cable assemblies are the preferred choice of design teams for early prototyping, standardized interfaces, and applications where connector pinout, orientation, wire gauge, performance, and shielding requirements comply with industry standards.

But there comes a time when system requirements start getting more specific, and off-the-shelf cable assemblies no longer fully align with them. At this point, it becomes impossible to proceed without compromises.

Practical challenges that commonly arise include:

Compatibility limitations: Off-the-shelf connectors may not always come with the required pin count or housing shape to match the custom PCB, enclosure, or equipment interface where they are supposed to be installed.

Rigid configurations: Cable lengths, wire gauges, and pin assignments come with preset lengths that limit the possibilities of routing the cables efficiently inside compact or irregularly shaped assemblies.

Electrical performance gaps: Off-the-shelf cables may not always support required current levels, voltage thresholds, impedance targets, or shielding needs.

Environmental exposure: Most catalog assemblies are not built to endure moisture, dust, vibration, or chemical exposure, and therefore are unsuitable for replacing custom sealed or IP-rated interconnects in harsh environments.

Mixed signal and power needs: Integrating low-voltage signaling and high-current paths in a unified assembly often requires a tailored design. Standard harnesses don’t typically support mixing signal and power interconnects.

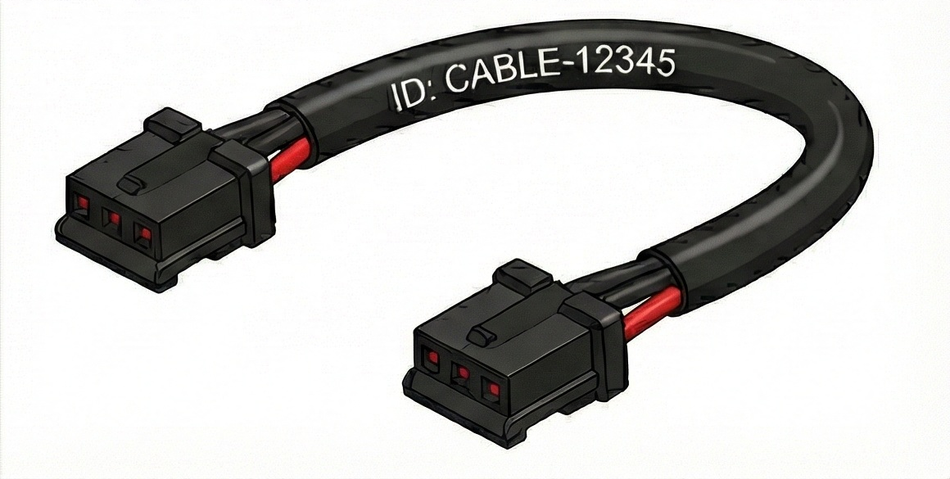

Labeling and cable management: Standard cable assemblies do offer a lot of color choices, but to effectively identify, trace, group, and organize cables, designers need to specify unique color codes and add printed labels to the cable jackets, which is only possible with custom cables.

Compliance assurance: Meeting industry-specific standards like ISO, IPC WHMA 620, IATF, or medical/HVAC requirements necessitates controlled manufacturing processes.

Streamlined Prototyping and Lead Times: If connectors, wires, and accessories are provided by different suppliers, the prototyping process may get complicated and lengthen lead times. In such situations, opting for custom assemblies built fully by a single supplier is preferred.

These are just some of the challenges that illustrate why engineering teams reach a point where standard cable assemblies are no longer sufficient. When performance, reliability, and integration demands increase, custom cable assemblies offer the required flexibility needed to align the characteristics of the interconnect with the final product.

Customization Possibilities with Molex

Molex offers vertically integrated capabilities that empower design teams to customize every feature of an interconnect to achieve this precision. When combined with Sager’s accessible customer engagement and support ecosystem, these capabilities help engineers swiftly move from concept to production.

Molex provides the following customization options:

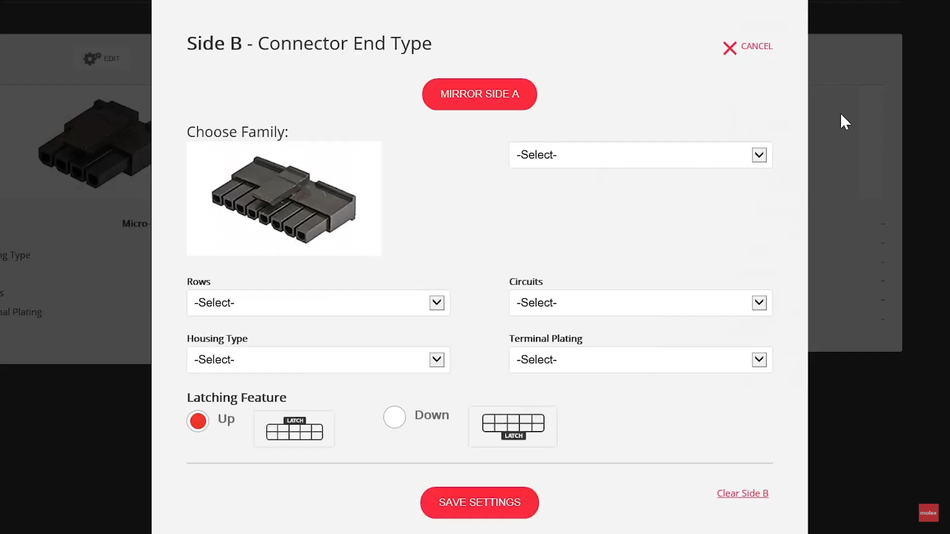

Connector Selection and Interface Design: Molex offers a broad range of connector families and interface options that let engineering teams define orientation, keying, pin count, terminal plating, locking features, and more to fit the constraints of their system.

Cable and Conductor Options: Customers can pick the conductor material, gauge, and insulation for their signal, power, or hybrid assemblies.

Overmolding and Sealing: For environmental sealing and managing strain, overmolding material options such as PVC, TPE, nylon, and PBT are available. Sealed variants achieve IP ratings needed for operation in harsh conditions.

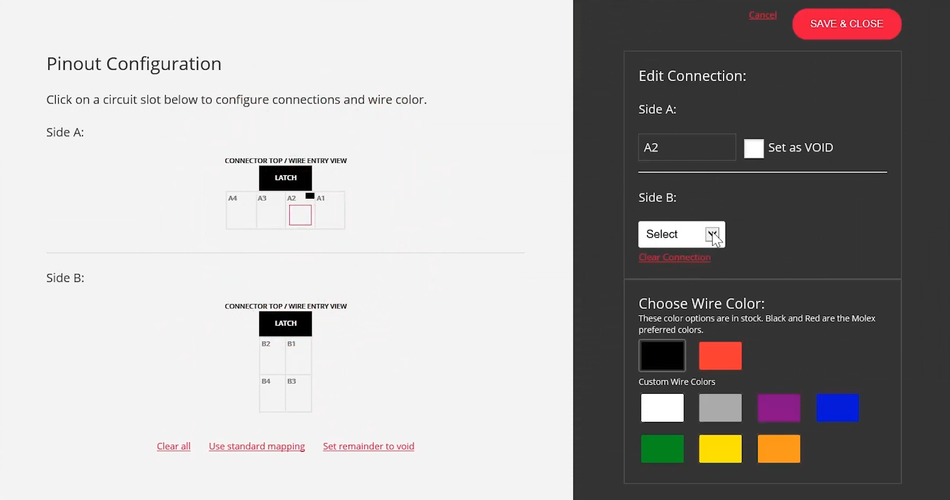

Electrical and Mechanical Configuration: Everything from pin mapping to shielding can be customized so that the custom cable assemblies support high-speed or high-power designs. The interconnects can be branched and routed as per the requirements to refine integration within the product enclosures.

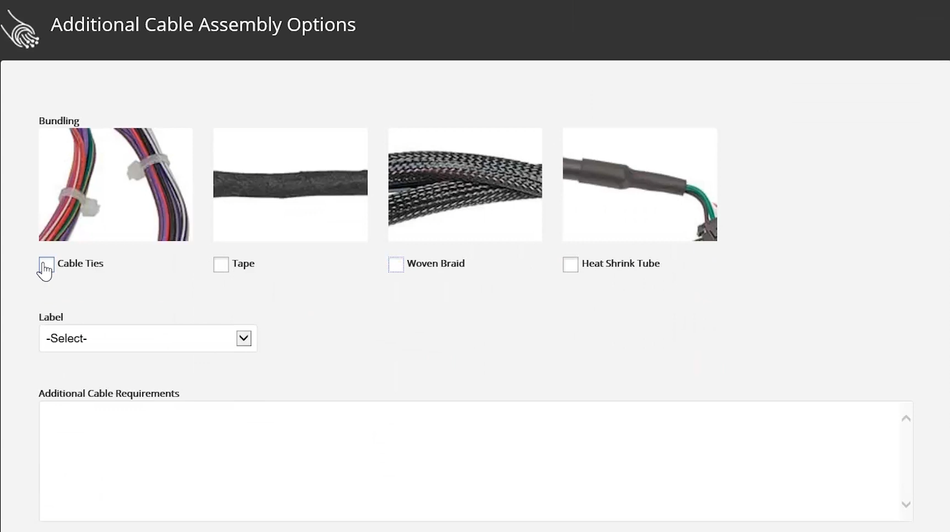

Labeling, Bundling, and Finishing: Whether it is custom labeling, color coding, or bundling options, customers can pick whichever suits them the best. For bundling, heat-shrink tubing, woven sleeves, cloth tape, or cable ties are also available.

Testing, Validation, and Compliance: Custom assemblies at Molex undergo automation testing for continuity, insulation resistance, and structural integrity. Molex ensures compliance with various international standards such as ISO 9001, IATF 16949, and IPC WHMA 620, helping ensure consistent quality and compliance.

When paired with Sager’s prompt communication, regional logistics, and support during early design stages, engineering teams receive cable assemblies that perfectly match the demands of their applications.

Molex Custom Cable Assembly Solutions Portfolio

Molex offers a portfolio of cable assemblies that cater to a wide range of electrical, mechanical, and environmental requirements. These product lines act as a foundation for custom designs, giving engineering teams a starting point and the building blocks to solve the unique challenges of their specialized applications.

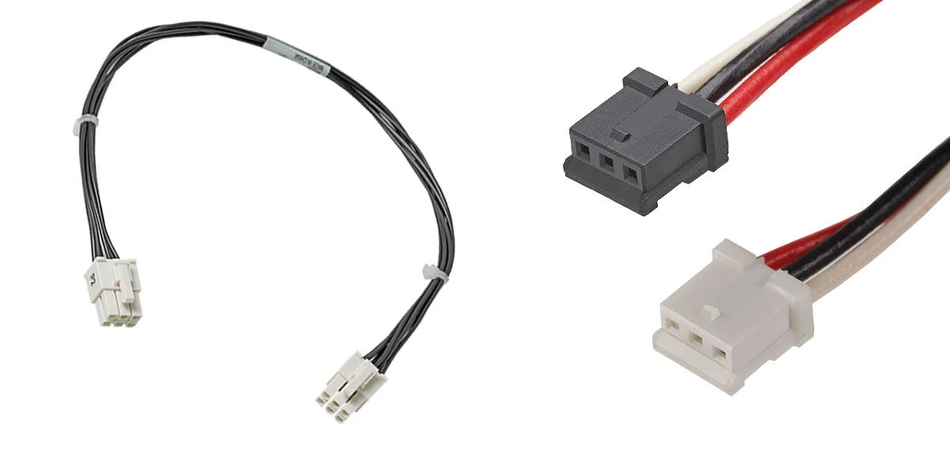

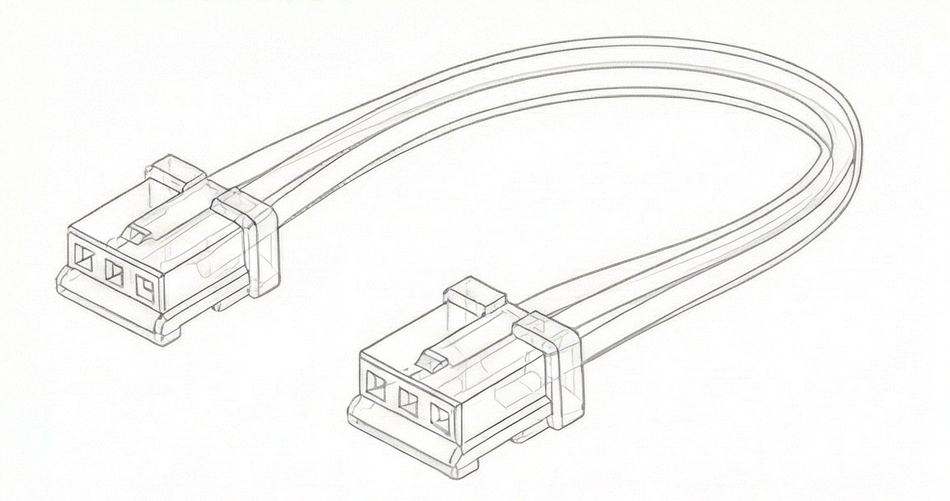

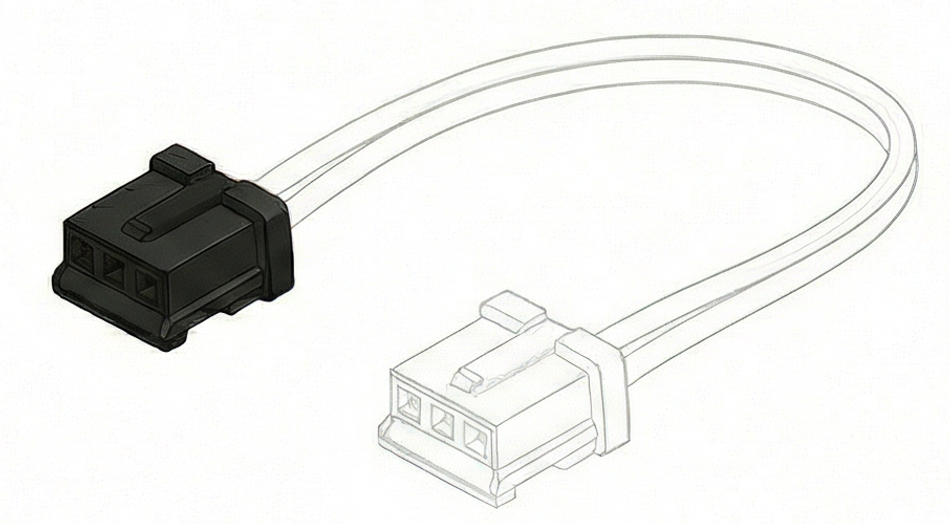

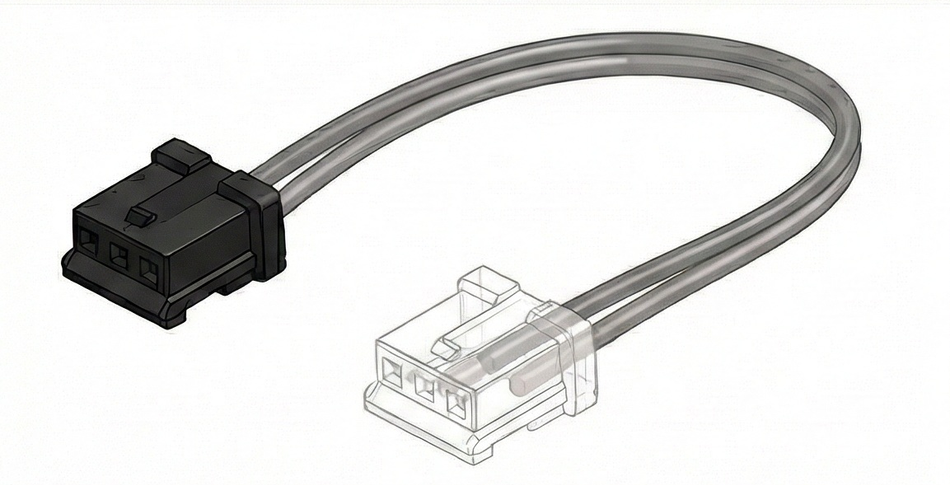

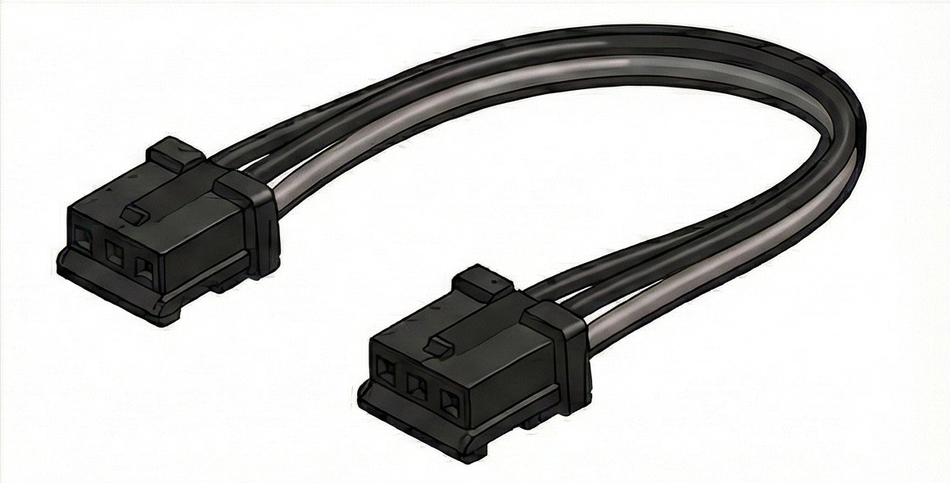

| Discrete Wire Assemblies Customizing the routing is often the most basic requirement for any custom cable assembly. These assemblies offer just that. Users can decide between single- or dual-ended connections, straight or branched orientations, and the ability to incorporate twisted pairs, ferrite cores, labels, and dressings. Discrete wire assemblies are extensively used in consumer products, industrial equipment, and automotive modules due to their simplicity and broad compatibility. |

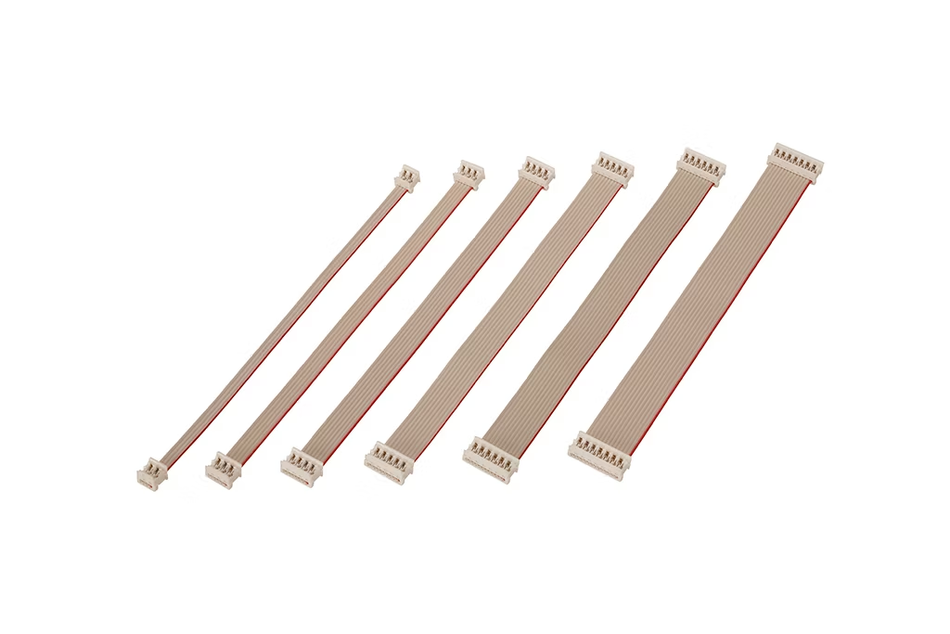

| Ribbon Cable Assemblies These cable assemblies excel in applications where movement is involved. Molex offers ribbon cable assemblies using insulation displacement termination (IDT) in various lengths and circuit sizes. |

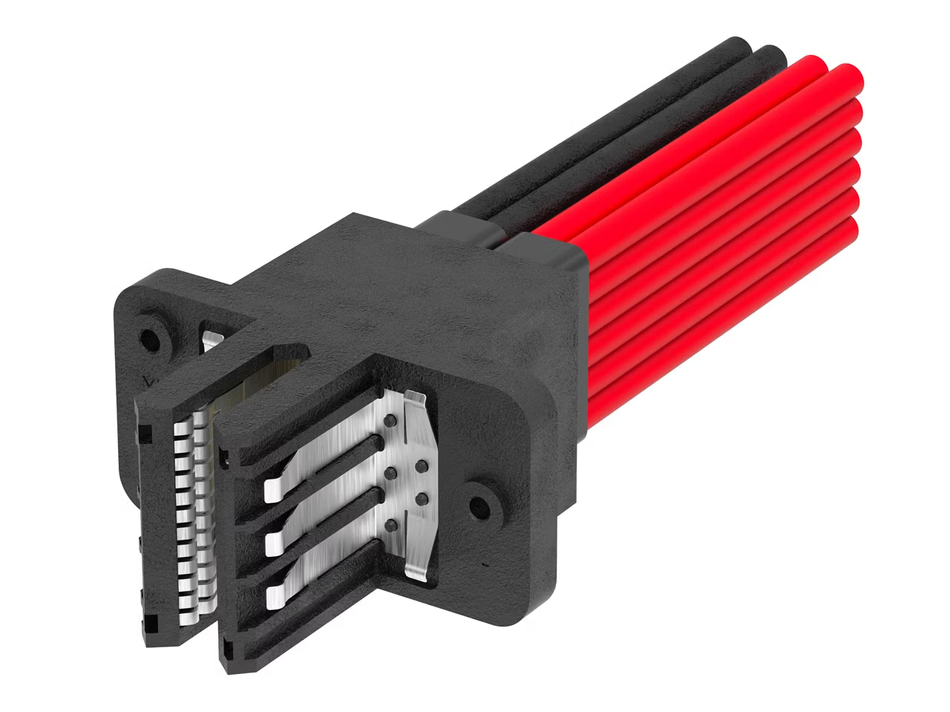

| High-Power Assemblies Molex offers high-power assemblies that use 6-12 AWG wire to handle current levels ranging from 30-80A. These can be constructed in discrete or overmolded forms and are compatible with Mega-Fit Connectors, EXTreme Ten60 High-Power Connectors, and EXTreme Guardian Systems, among others. |

| Overmolded Assemblies In environments where the interconnects are subjected to excessive stress and wear, Molex offers overmolded cable assemblies with enhanced mechanical strength and environmental protection at the connector-cable interface. Materials like PVC, TPC, nylon, and PBT are used to provide strain relief. |

| Sealed Plug and Socket Assemblies For outdoor environments and conditions where there is a risk of ingress, Molex offers sealed plug and socket assemblies that come with strong seals and gaskets. These custom assemblies offer high resistance to dust, water, and vibrations by meeting stringent protection ratings of IP67/IP69. |

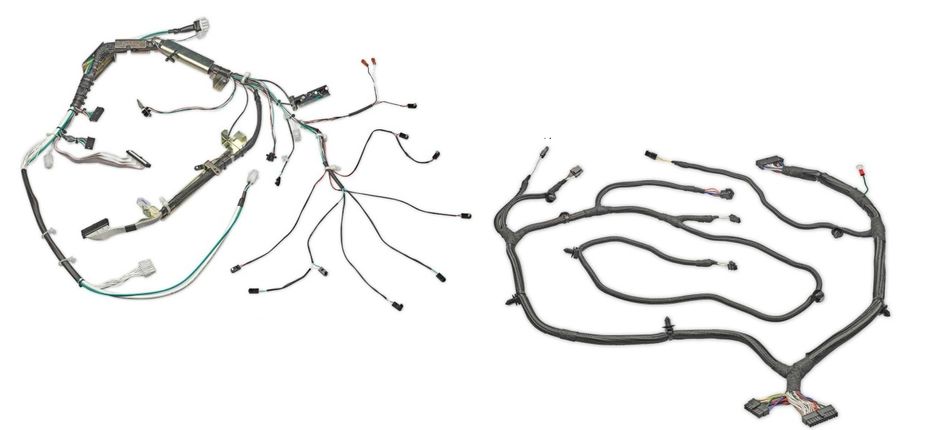

| Complex Multi-Breakout Assemblies When systems require multiple connectors, mixing of signals, or branching, complex cable assemblies from Molex offer flexibility through a variety of different methods. These assemblies can include overmolded sections, multiple breakout points, or mixed power and signal pathways, enabling a complete solution from a single vendor. |

| Sensor Cable Assemblies A specialized offering by Molex enables customers to build cable assemblies with just about any sensor. These products can be ruggedized with different types of sealing options. |

Whether it is a simple point-to-point connection or a highly complex multi-harness design, Molex provides a solid platform for building custom cable assemblies that get the job done.

Molex Custom Cable Creator: Step-by-Step Guide

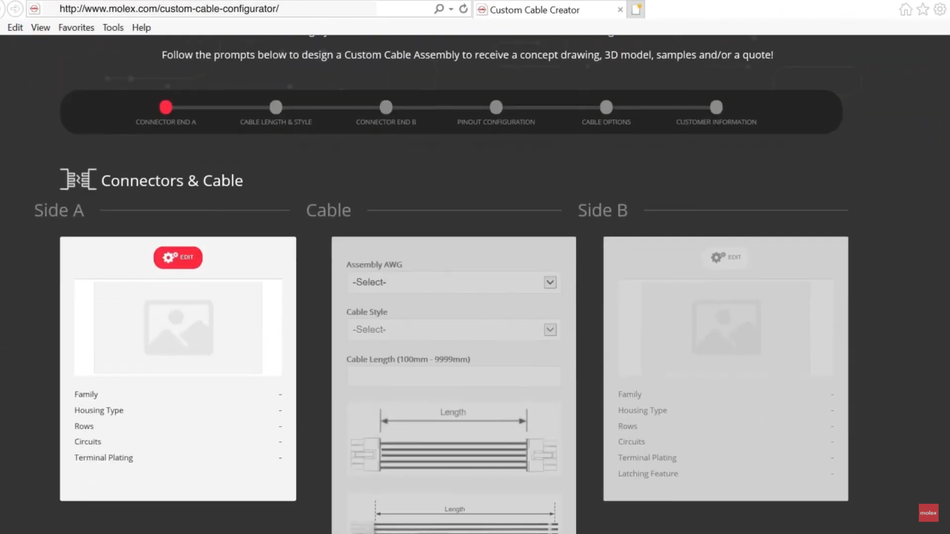

The Molex Custom Cable Creator simplifies the whole process of configuring a custom cable assembly from scratch. Instead of finding out and specifying each and every parameter, customers can make use of a clean, point-and-click interface to go from concept to validated design.

The software includes a comprehensive component library that automatically generates drawings and quotes, enabling engineers to build application-specific assemblies quickly. The configuration workflow typically follows these steps:

| Getting startedThe user logs in to the custom cable creator. |

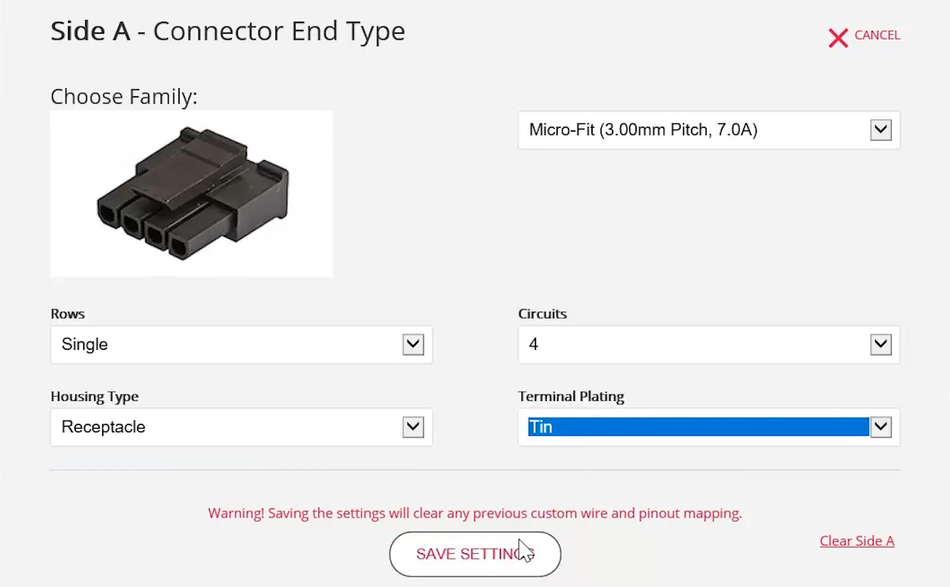

| Configure Side AThe process begins by defining specifications for one end of the cable. The user selects the connector style, circuit size, orientation, and related parameters for Side A. |

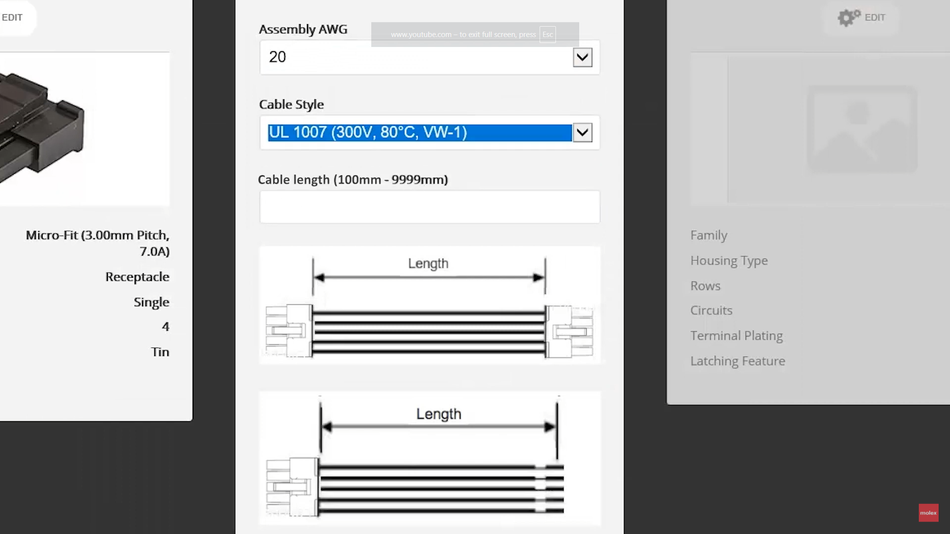

| Specify cable parametersThe user then defines cable attributes like the wire gauge, cable style, UL type, and overall length. |

| Configure Side BNext, the user configures Side B, which can mirror Side A, use a different connector family, or be configured without a connector as a single-ended cable with stripped leads. |

| Configure PinoutIn this step, the user can apply standard or custom pin mapping. They can also set wire color assignments and void positions. |

| Select additional options as neededCable ties, braid, tape, heat-shrink tubes, and custom-printed labels can be added to support routing, assembly, or service needs. |

| Review and samplingOnce the design is ready, users need to enter contact information, project details, and additional notes to receive auto-generated 3D models and PDF drawings. This makes it easier to validate mechanical fit and reduce design ambiguity. Quotes are typically made available to users within one to two business days, and samples can be produced within approximately one week. |

Having a simple and efficient tool for the process improves design accuracy, reduces rework, and accelerates the transition from requirement to prototype.

Diverse Application Examples

Cable assemblies play a key functional role in all electrical systems. The combined capabilities of Molex and Sager support projects across multiple industries, enabling assemblies that align tightly with application-specific constraints. Examples of the industries benefiting from these solutions include:

| Data Centers: To maintain signal integrity in systems where data is transferred in large amounts, high-bandwidth interconnects with controlled impedance, optimized shielding, and robust connector-cable transitions are required. Custom interconnects ensure predictable performance across high-speed links, power distribution units, and server infrastructure. |

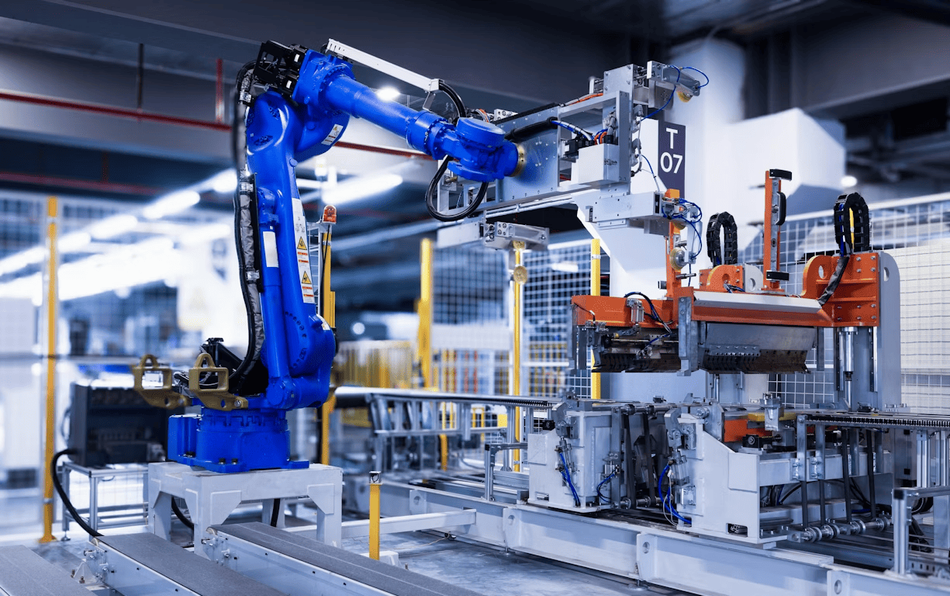

| Industrial Automation: In factories, robotic systems operate in environments with extreme vibration, dust, and mechanical stress. Custom-designed rugged harnesses, overmolding, and sealing techniques help users build systems that withstand these harsh conditions while supporting reliable signal and power routing. |

| Automotive and Electric Vehicles (EVs): The complexity of onboard electronic systems in automobiles is increasing, driven by the widespread adoption of EVs and software-defined vehicles (SDVs). Custom cable assemblies are required in components such as chargers, battery management systems, motor control drives, and other automotive electronic systems. These systems are regularly exposed to vibrations, temperature fluctuations, and fluids and require different custom cable assemblies that support mixed signals and high power and come with sealed, vibration-resistant harnesses. |

| Medical and HVAC: Applications driven by sensing benefit from assemblies that integrate thermistors, Hall-effect sensors, or other detection elements. Medical instruments often include a lot of moving parts, which need flexible cables. With custom cables, engineers can ensure precise routing, insulation, and connector design for extra reliability in monitoring, control, and diagnostic equipment. |

| Consumer Electronics and Appliances: Consumer electronics is a broad segment that covers major home appliances, kitchen appliances, personal devices, gaming consoles, and more. For optimizing the products and getting them ready for production, a number of different custom cable assemblies are used. |

Case Study: Thermistor Cable Design

Monitoring temperature is a key aspect in many heating, ventilation, and air conditioning (HVAC) and thermal-control systems. Engineering teams working in this area often require sensor-integrated cable assemblies that give out accurate readings across defined temperature ranges while meeting the mechanical constraints of the equipment. This example illustrates how an HVAC engineer leveraged Molex tools and Sager’s support to develop a thermistor-based cable assembly.

The design process started with the selection of the sensing element. Using the Molex NTC Thermistor Calculator, the engineer defined the required resistance-temperature profile by entering the Beta value, nominal resistance at 25°C, and target temperature range. The tool recommended a suitable thermistor based on the input parameters. With the help of a resistance curve, the engineer could confirm the suitability of the chosen thermistor for the target application. Once the sensing characteristics were validated, the engineer configured the physical assembly.

The connector family, wire gauge, insulation material, and cable length were selected based on installation requirements. The engineer had a choice to set thermistor leads to terminate, overmold, or seal, depending on environmental exposure. Side A and Side B configurations were defined, followed by pin mapping and bundling selections.

After submitting the design, the engineer received a 3D model and drawing to verify the fit. Sager coordinated the quoting and sample delivery steps and enabled rapid iteration to accommodate the minor adjustments that were needed afterwards.

With the end-to-end custom cable assembly solution by Molex and Sager, the engineer could build a validated, application-specific thermistor cable that perfectly met both sensing and mechanical requirements of the intended application. This streamlined workflow, reduced engineering time, minimized rework, and provided a predictable path from concept to prototype.

The Molex-Sager Collaboration Model

Molex and Sager Electronics share a common goal: making it easier for engineering teams to move from initial requirements to production-ready cable assemblies with clarity, speed, and confidence. Instead of a transactional supplier-distributor relationship, the collaboration between Sager and Molex operates as an integrated workflow that combines the engineering depth of Molex with Sager’s customer accessibility and responsiveness.

Molex offers comprehensive design and manufacturing expertise for custom cable solutions with global facilities. This sophisticated infrastructure enables consistent quality, traceability, and scalability across both low-volume prototypes and high-volume production projects. Molex engineers also support users with application reviews, manufacturability assessments, and design refinements to make sure that each assembly meets the required electrical and mechanical constraints.

Sager complements Molex by offering support throughout the quoting, design, and fulfillment stages. Sager teams help clarify requirements, coordinate communication, and ensure that customer feedback is incorporated quickly. Sager integrates directly with the Molex Custom Cable Creator workflow to provide fast turnaround on pricing, design adjustments, and sample requests, effectively reducing friction during development.

Together, Molex and Sager create an end-to-end process that moves through the following stages:

Concept

Configuration using digital tools

Quote generation

Prototype manufacturing

Production launch

This model helps engineering teams reduce development cycles and align design intent with manufacturability. By offering both deep technical capability and accessible customer engagement, the Molex-Sager relationship provides a reliable pathway to build cable assemblies optimized for specific applications.

Conclusion

Cable assemblies are responsible for carrying electrical power and signals from one point to another. As performance and mechanical design constraints grow, design teams need solutions that may not always be available as standard catalog offerings from suppliers.

To match the exact needs of the application, engineers can make use of custom cable assembly solutions by Molex and Sager that provide a straightforward path from concept to production. By offering top-of-the-line performance, consistent quality, and predictable lead times, engineers can avoid making compromises by picking off-the-shelf solutions.

To begin configuring a custom cable assembly, explore the Molex Custom Cable Creator or contact the technical team at Sager Electronics via this short form for application-specific support.