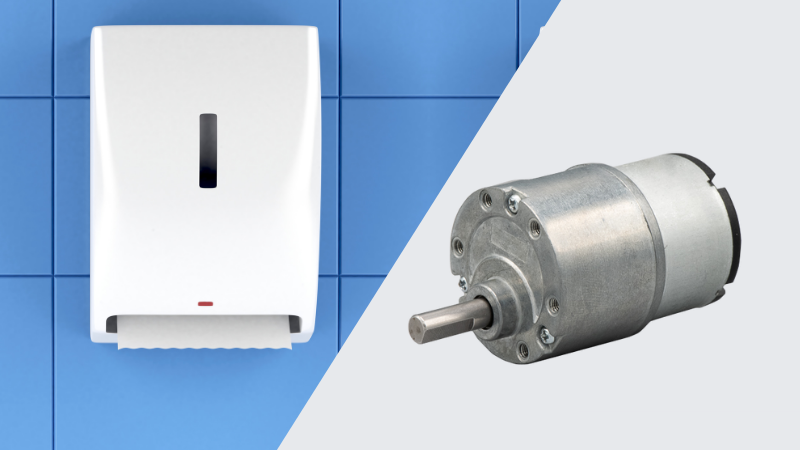

6V DC Spur Gear Motor for Hands-Free Products: Automated Paper Towel Dispenser

Low Current Draw Gear Motor Designed with Efficiency in Mind!

Low Current Draw Spur Gear Motor

This article was first published on

islproducts.comHands free products have become increasingly popular and even more important during the COVID-19 pandemic. Ranging from an automatic paper towel dispenser to soap and hand sanitizer dispensers, people expect these types of products to be available in public areas.

Typically, a touch-less paper towel dispenser is run by a 6V DC motor or gear motor. These applications are usually designed to run off of batteries. To maximize time between battery changes the motor must be extremely efficient.

ISL Products offers low current draw, high torque 6V DC motor and gear motors designed specifically for battery powered devices. These efficient motors are not exclusive to paper towel dispensers, they are also great additions to other 6V appliances like:

Soap Dispensers

Sanitizer Dispenser

Touch-less Faucets

Touch-less Sinks

Automatic Garbage Lid Openers

These efficiency-focused motors are available as both DC motors or DC gear motors, making them ideal for most applications.

Overview

A leading manufacturer of a battery-operated paper towel dispenser was experiencing shorter than desired battery life during product use. The dispenser was using a 6V DC spur gear motor that was drawing too much current, creating a significant drain on the product’s power bank of batteries.

Challenge

The customer tasked us with developing a direct drop-in replacement spur gear motor that would draw 25% – 50% less current than their existing motor.

During our investigation of the incumbent gear motor we found that the current draw was 800 – 850mA. Additional investigation of similar motors, from several manufacturers, showed a range of current draw under load from 800mA – 1400mA. The customer requested that we find a way to reduce that current down to 600mA or less.

Another issue we came across was that, over time, excessive brush and commutator wear escalated the current draw problem even further.

Solution

ISL Products International and our team of engineers tore down the incumbent motors and found a variety of factors that contributed to the higher current draw issue that our customer was experiencing. In addition to the excessive brush and commutator wear, in some cases we found foreign conductive material floating within the motor itself creating unwanted spikes in the current draw.

The ISL engineers and our factory’s engineering department agreed on a methodology for improving the motor quality and bringing the current draw in line with the customer’s expectations. The current draw was reduced by improvements to the armature windings, and the addition of high-quality brushes increased longevity and removed the wear problem. Our factory's good manufacturing practices guaranteed precision tolerances and high quality material sourcing, as well as preventing foreign conductive material from floating in the motor like that found in the incumbent motor.

Once the new motors were created they were tested and showed minimal wear patterns while having a current draw of 590mA.

Conclusion

After implementing the ISL motor in their contact-less paper towel dispenser the client achieved the desired battery life of the device. The client was able to avoid designing and implementing a new battery system by replacing a single part in their device. This dramatically reduced the cost of increasing battery life and reduced service time by the end user.

These motors have dispensed hundreds of thousands of paper towels in locations from airports to arenas and will continue to do so for a long time.

If you are facing a component challenge, reach out to ISL Products so that you can discover a value-added solution.