3D printing for construction and architecture projects

Is 3D printing the future of construction? Can it really become an alternative to traditional construction techniques in the future? That’s what we are going to see!

architecture and 3D printing

Here is the ultimate guide of 3D printing in construction. We will tell you more about the benefits of 3D printing for the construction industry and we will see what are the different technologies developed in order to revolutionize this sector.

Is 3D printing the future of construction? Can it really become an alternative to traditional construction techniques in the future? That’s also what we are going to see! You will find some information about the first experiments of 3D printed houses or 3D printed buildings, but more importantly, we will see how additive manufacturing could be helpful for you and your projects. How could you use it at your scale? For which projects?

We hope you will be inspired by all these incredible architecture projects.

Why you should start using 3D software for architecture

The advantages of 3D printing start with the use of the right 3D software. Finding the right architecture software can be complicated, from ArchiCAD to Revit a lot of programs are dedicated to architecture and offer great toolsets.

Why are these software so useful? Even if you are not planning on using 3D printing, these programs can help you to get a better visualization of your projects, for you and your customers. You will be able to produce a photorealistic rendering, as well as do and re-do your 3D models until it matches your expectations.

Thanks to these advanced software, you can turn any of your ideas into detailed models and designs. Moreover, a 3D modeling software using the Cloud will offer you the opportunity to optimize the collaboration and communication in your team. Your work will be accessible to anybody, and you’ll all be able to work on the same model.

Benefits of 3D printing for construction

Now that you know a little about how it’s done, let’s discuss why we do it. One might think we have good technologies for building different structures, we make stable houses, apartments, and offices, is there still room for improvement? Oh yes. Rebuilding whole cities after a natural disaster, giving shelter to homeless people and generally building more sustainable habitats- those are only a few problems that 3D printing can help with.

Fast production

3D Printing in the construction industry means greatly reduced production time. That’s because the machines themselves are very fast, some of them are capable of manufacturing 600 to 800-square-foot (55 to 75-square-meter) home in just 24 hours. Sounds amazing, doesn’t it? 3D printers are also fully automated, which eliminates human error. The machine just needs to be monitored, but most of the production process doesn’t involve any human help. Also, 3D printers don’t use additional tooling. They have the construction programmed and they just produce it, there is no need for additional support, different materials, and other aspects to keep in mind that traditional methods require. https://hypepotamus.com/news/new-story-unveils-3d-printed-home/

Almost zero material waste

The main advantage of using 3D printing in the construction industry is saving a lot of production costs on material waste. That’s because a 3D printer, such as robotic arms, uses exactly the amount of material they need. Producing buildings layer by layer and with lattice structures inside allows for a huge cost reduction. Not only that, but they are also capable of using recycled materials. This factor also benefits the environment. 3D printing has a much smaller impact than traditional ways of manufacturing. An Italian company called WASP took 3D printing into a great development and designed one of the largest 3D printers in the world capable of producing homes out of local materials and using green energy (hydro, wind or solar power). This means much smaller emission, which is a big problem in today’s construction industry. Last year we talked about the first family to move into a 3D printed house. The house in question was produced in Nantes, France and is called the Yhnova project. It took only 54 hours to print the house and the overall cost was about 20% cheaper than building a traditional house. Additive Manufacturing can really help to build a better future for the construction industry.

Cost-effectiveness of 3D printing in the construction industry

As mentioned above, using Additive Manufacturing allows for less material usage and involves fewer people to work on construction. 3D printing is also a much faster technology. Those factors radically reduce the costs of building any 3D printed construction. While 3D printing structures, we use just the amount of material we need, therefore we are eco-friendly and save money. This aspect can really bring the costs down. 3D technologies also reduce supply costs. We can also save a lot of time, 3D printers don’t need to eat or sleep, their working hours are more adjustable and they are a lot faster than people. And the faster you build, the more money you save.

Innovative design

The last, but just as important benefit of using 3D printing in the construction industry, is all the innovative solutions it brings. 3D technologies can improve your project planning as they can be used already at the design stage. Starting from CAD plans of the buildings, which are technical drawings with all the parameters. Based on those drawings, a 3D model of the construction can be made to meet the clients’ expectations and show them the best design solutions. Addressing the client’s issues and presenting the right answers to their questions is crucial. Additive Manufacturing helps here. As we just mentioned with 3D technologies, you can present your clients with 3D visualizations of the structure, but that 3D model can be 3D printed.

One of our clients, Valoptim, did just that! The family could imagine themselves already living in the house. These models allow for high personalization of the structure.

Moving on to large scale projects, Additive Manufacturing gives us new design freedom allowing for the production of new shapes and solutions to our needs. We have never had such a great possibility to customize structures. Not only the structures themselves but also the locations. It’s easier to set up a 3D printer somewhere for a few days than move all the workers there. Also, some of the machines don’t even need electricity as they run on green energy, which means that we can reach undeveloped areas easier.

What are the different technologies

To start talking about Additive Manufacturing applications for construction, we should first have a look at the available technologies, then we can discuss the advantages. Right now, we have a few options to use 3D printing in the construction industry.

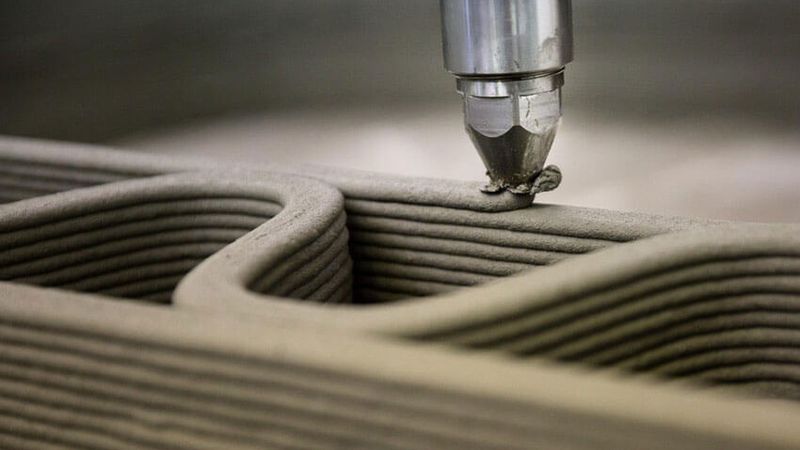

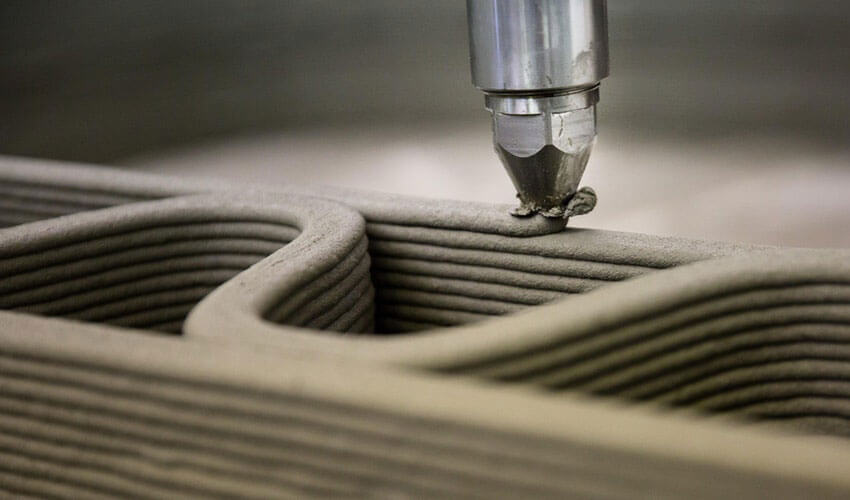

Robotic arm extruders

One of them is a robotic arm extruder, this technology is called contour crafting. It is fairly similar to how FDM desktop 3D printers work. The rails are arranged to let the robotic arm move; and within the limits of the rails, the arm will build the house layer by layer by extruding concrete material from the nozzle. This is the most popular 3D printing technology used to build XL structures.

Credit: XtreeE

Sand 3D printing

The next 3D technique is more similar to industrial 3D Printing such as SLS or Jet Fusion. The pioneer who tested it is the Italian architect Enrico Dini, who built his D-Shape 3D printer. The machine spreads a layer of sand powder, then hardens the shape of the structure with a binder. This is exactly how our metal 3D printers work too!

https://www.3dnatives.com/en/3d-printing-construction-310120184/

Metal technology

Last but not least, for structures such as bridges, which have to withstand more stress, Dutch company MX3D developed Wire Arc Additive Manufacturing (WAAM). The team described the technology: “we combined an industrial robot with a welding machine to turn it into a 3D printer that works with our own software”. The robot allows for 3D printing metal structures in 6-axes.

https://www.3dnatives.com/en/3d-printing-construction-310120184/

The best 3D printed construction projects

We talked a lot about the benefits that Additive Manufacturing brings into the construction industry. 3D printing opens new design possibilities, brings the costs down and produces sustainable construction projects with low environmental impact. We talked theory before, now let’s move on to how the advantages of AM are applied in reality!

We already told you about a family moving into a 3D printed house in France and many 3D printed houses projects. In the other real-life examples, we will introduce you to some stunning projects from the Netherlands, to Dubai’s 3D printed offices, to the first-ever 3D printed bridge. How about manufacturing a house in one day? Is it possible? Let’s see how far the 3D technologies for the construction industry have come.

Build a House in 24 hours?

Why not! Apis Cor is a Russian company specializing in 3D printers that can produce a contour-crafted home in just 24 hours. Not only that, but the machines can also work in winter, they just have to be covered. 3D printers can be easily transported to the building site and within 30 minutes it’s ready to build your future house! The concrete is a special mix that hardens fast, allowing the printer to work fast. The company wanted to showcase also that the shape of buildings doesn’t have to be square, we can open architecture to take new forms. With experiments like this one, we can see that additive manufacturing could become a serious solution to the housing crisis in the upcoming years.

3D printing a new life

New Story is a nonprofit organization whose mission is to bring homes to the poorest. They have built 850 houses worldwide in 3 years, but they knew they have to work faster. Brett Hagler, the CEO and co-founder of New Story, saw the potential of Additive Manufacturing. They developed new designs and construction solutions, enormously improving their building process and bringing the costs down. Thanks to 3D printing they were able to manufacture 100 contour crafted homes in just 8 months. That’s more than 12 houses per month, and for the organization, that means 12 families that finally received homes.

New Story was able to achieve so much thanks to a collaboration with Icon, who design the Vulcan mobile 3D printer. The machine can be easily moved to developing countries and can operate even without electricity. The printer is capable of building a 600 to 800 square foot house (55- 75 square meters) in just 24 hours. Thanks to 3D technologies the costs are established to be just 4 000$. This can truly change the future of housing and fighting homelessness.

https://www.artsy.net/article/artsy-editorial-inside-race-perfect-3d-printed

An innovative form of offices: building offices of the future

3D printing brings new forms into construction. Thanks to Additive Manufacturing the architects are no longer limited when it comes to abstract forms of the office building and Dubai’s new offices proved that. They produced new, futuristic structures, assembled in just 17 days by 17 professionals. They are equipped with energy-saving devices, which is very cost-efficient. But also using 3D printing for construction already brought the labor costs down by 50%! Utilizing Additive Manufacturing allowed for massive cost reduction and was much faster than the traditional building process.

https://inhabitat.com/dubai-debuts-worlds-first-fully-3d-printed-building/

Stunning and marine-inspired facade

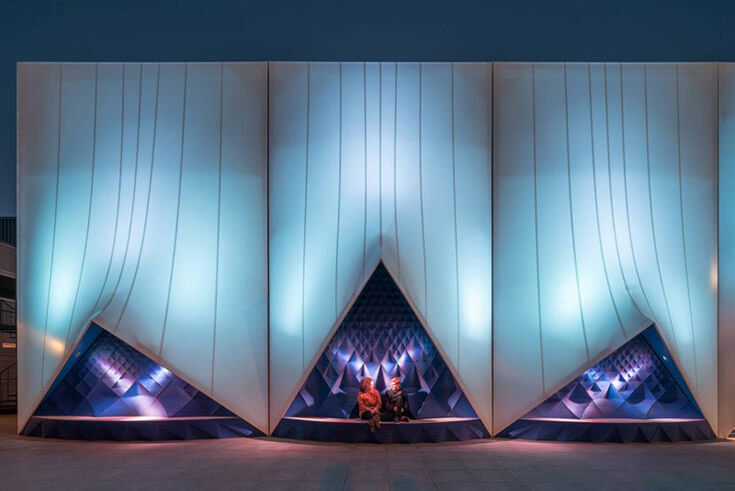

In 2016 the Netherlands was holding the Presidency of the Council of the European Union and to celebrate such important leadership a new facility was built for the politicians to gather. It was not just an ordinary, boring building. Given new design freedom by 3D printing, the architects built the extravagant facade, closely resembling a sail stretched over the building.

The curtain-like slits uncover blue benches which were 3D modeled geometrically and manufactured locally with a construction 3D printer. This innovative structure was produced with bioplastic, which was developed especially for this occasion. When the Dutch EU Presidency came to an end, the building was taken apart and the bioplastic was recycled to be reused for future 3D printing projects, which promotes and proves that the construction industry can have low environmental impact thanks to 3D technologies.

https://www.detail-online.com/blog-article/3d-printed-europe-building-by-dus-architects-26804/

3D printed bridges

Additive Manufacturing in the construction industry is not just about buildings. Applications of 3D printing can also be highly beneficial to manufacture bridges. Thanks to the ability to create some really complex structures, but also build strong, durable constrictions. We actually just wrote about the longest 3D printed bridge in the world printed recently in China!

But it wasn’t the first pedestrian bridge ever. The pioneers in 3D printed bridges were the Netherlands. The construction in question was built for cyclists. It could handle the weight of 40 trucks and thanks to Additive Manufacturing is sustainable! The Netherlands seems to really see the potential of 3D technologies as the next project is also Dutch.

This bridge came to life with 3D technologies and was designed by MX3D. The company developed a special robotic arm that was capable of 3D printing with steel. This impressive construction has an abstract and bio-inspired design and the bridge basically builds itself thanks to 3D software the engineers elaborated.

3D printing homes with rice?

Additive Manufacturing is a great way to bring more sustainable architecture to life. Wasp, an Italian 3D printers manufacturer, developed the Gaia project. They manufacture contour crafted buildings with almost no material waste. The material used is raw earth and rice waste, both of which we have plenty. The structure of the walls allows for thermal insulation and natural ventilation. This project perfectly showcases that eco-friendly and fully functional architecture is totally possible thanks to 3D printing.

Concrete 3D printing

Eindhoven is known for its many 3D printing concrete experiments. But do you know that a project of 3D printed concrete houses is planned in Eindhoven? This project will start to be 3D printed in the Eindhoven University, using concrete 3D printers, and move progressively on the construction site. The goal here is to allow the construction of fine architectural designs while keeping in mind some sustainability aspects by avoiding material waste and CO2 emissions.

What is the future of 3D printing for architecture?

As you can see there are plenty of benefits to using 3D printing in the construction industry and the companies using it already are very successful. 3D technologies help to manage the whole production process, from the early stages of the project to produce it. Structures are being 3D printed at a fraction of the regular cost and time, they are much more eco-friendly thanks to almost zero material waste.

But besides these incredible experiments pushing the boundaries of the technology, you can access some amazing technologies such as SLS to create your next architectural models and rethink the way you develop your mockups and construction projects.

Innovations that Additive Manufacturing bring are available not only in the construction industry but you can also improve your production today, with us. We offer you different 3D printing technologies, from plastic 3D printing to resin 3D printing and metal. Don’t wait for your competitors to do it, bring this cutting-edge technology to your business today.