Wireless battery-free wearable sweat sensor powered by human motion

Fully motion-powered wearable device that measures pH and sodium concentration from sweat

Technical Specifications

| Charging/Discharging cycle Time | 2.1 to 3.7 |

| Stator dimensions | 37.8 x 59.8 |

| Stator weight (one panel without PTFE coated) | 0.586 |

| Stator weight (one panel with PTFE coated) | 0.782 |

| Slider dimensions | 43.6 x 41.8 |

| Slider weight | 0.396 |

| Operating Frequencies | 0.5, 1.25, 3.3 |

| Maximum ISC | 8.39, 19.11, 42.25 |

| Maximum power output (1.5Hz, 4.7 megohms) | 0.94 mW / 416 mW |

| Sensor patch | |

| Ag/AgCl electrode material | polyvinyl butyral (PVB) |

| pH electrode material | electrodeposited polyaniline (PANI) |

| Na+ electrode material | Na+ ionophore X, PEDOT:SS |

| pH sensitivity (pH 4-8) | 56.28 |

| Na+ sensitivity (Na+ concentration 12.5 to 200 mM) | 58.63 |

| Low-Power Biosensing Circuitry | |

| Maximum Storage Capacity Voltage | 3.5 |

| Minimum Storage Capacity Voltage | 2.2 |

| Load/Output Voltage | 2.2 |

| BLE PSoC operation cycle | 510- |

| Watch Crystal Oscillator (WCO) | 32- |

| Deep Sleep/Maximum Startup Time | 500 |

Overview

Problem / Solution

Wireless wearable devices provide a noninvasive way of measuring physiological parameters in real-time and transmitting continuous data to a user device. Sweat is a readily available specimen containing a wide range of molecular biomarkers relevant to health status.

Current wearable sweat sensors, however, have battery, power, and consumption issues: bulky and rigid batteries, unreliable flexible batteries, and small coin-cell batteries, and the limited operating range of NFT-powered devices. One effective solution to the wearables' sustainable power problem is to generate energy through human motion that also produces sweat, which the biosensor detects.

Triboelectric nanogenerators (TENGs) can convert mechanical energy generated by human motion into electrical energy by coupling inductive and triboelectric effects to power the electronic circuitry. However, the majority of the current TENG-based devices have low power intensity, inefficient power management, and a lack of power continuity and longevity, rendering them unsuitable for continuous biosensing.

The FTENG-powered wearable sweat sensor system (FWS3) is a fully motion-powered wearable sweat sensor that includes a flexible and efficient freestanding triboelectric nanogenerator based on a printed circuit board (FPCB) (FTENG). During on-body human trials, the fully integrated battery-free triboelectrically driven system is able to power multiplexed sweat biosensors and wirelessly transmit data to the user interfaces through Bluetooth.

Design

The FWS3 is comprised of three major components that are seamlessly integrated onto a single flexible polyimide-based printed circuit board (FPCB) platform: a freestanding-mode TENG (FTENG), low-power wireless sensor circuitry, and a microfluidic sweat sensor patch.

Freestanding Triboelectric Nanogenerator (FTENG)

The FTENG is made up of an interdigital stator and a grating-patterned slider (Fig. 1D), both of which are made using commercial FPCB technology. The system generates electrical energy when the stator and slider physically rub against one other. Tribo-pairs of polytetrafluoroethylene (PTFE) and copper are used to achieve a strong electrification effect with optimized inter-electrode distance. The stator's circuit elements and interdigital electrode are fabricated using photolithography, while the slider's complementary grating structures are also fabricated using photolithography. PTFE is used to laminate the stator's electroless nickel/immersion gold (ENIG) surface finish on the electrode area.

The FTENG's operation is explained by the coupling effect of contact electrification and in-plane sliding-induced charge transfer. Electrons accumulate on PTFE during the sliding process because copper is more triboelectrically positive than PTFE. The charging flow between stator electrodes is caused by the unidirectional sliding process until the grating slider fully overlaps with the second stator electrode with reversed polarity.

The FWS3 is conformally laminated on the side torso with waterproof medical tape to maximize the potential for energy harvesting. The maximum power output of the FTENG is 0.94 mW or 416 mW m2, with a load resistance of 4.7 megohms and a working frequency of 1.5 Hz.

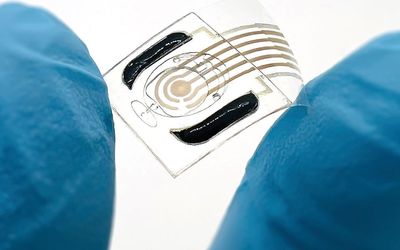

Microfluidic Sweat Sensor Patch

The ion-selective electrodes are the basis of the dual biosensor array used for sweat analyte analysis (ISEs). For controlled and automated on-body sweat sampling, laser-engraved microfluidic channels are assembled between two layers of polyethylene terephthalate (PET) sensor substrate.

The Ag/AgCl reference electrode is polyvinyl butyral (PVB) coated to maintain a constant potential for potentiometric measurements of various electrolytes despite the sweat's ionic strength. An electrodeposited polyaniline (PANI) layer for pH analysis is used to measure the deprotonation of H+ atoms on the layer's surface as an indicator of bulk H+ concentration. A thin ion-selective membrane sandwiched between the gold electrode layer and the sodium ion-selective membrane acts as an ion-electron transducer, reducing the biosensor's potential drift. A Na+ ionophore X and a poly (3,4-ethylenedioxythiophene) (PEDOT):poly(sodium 4-styrenesulfonate) (PSS) layer are used in these ion-selective membranes.

In physiologically relevant pH levels of 4 to 8, the pH sensors have sensitivities of 56.28 mV per decade concentration. While in physiologically relevant Na+ concentrations of 12.5 to 200 mM, the Na+ sensors have sensitivities of 58.63 mV per decade concentration. The pH and Na+ sensors exhibit high selectivity, reproducibility, and long-term stability. The measurements of the flexible sensors remain stable under different physiological temperatures, can conform to human skin, and demonstrate excellent mechanical stability in rigorous bending tests. As a result, it is suitable for wearable continuous monitoring in a variety of physical activities.

Low-Power Biosensing Circuitry

The low-power biosensing circuitry of the FWS3 is made up of a power management integrated circuit (PMIC), a low-dropout voltage regulator, two low-power instrumentation amplifiers, and Bluetooth low energy (BLE) programmed system on a chip (PSoC) module.

A commercial energy harvesting PMIC is used to manage the FTENG's power with minimal power waste. The high voltage AC generated by the FTENG is converted by a bridge rectifier into a DC signal. The PMIC then stores the FTENG generated power in two parallel capacitors (220 and 22 F). The capacitor accumulates the energy. When the storage capacitors’ voltage reaches 3.5V, the capacitors supply energy to the load to power a single measurement event. When storage capacitors’ voltage reaches the threshold voltage of 2.2V, the control unit of PMIC disconnects the capacitor from the load until it reaches 3.5V again. A voltage regulator sets the load/output voltage to 2.2V to provide a stable voltage for precise measurement.

The BLE PSoC module starts one ~510-ms operation cycle whenever the storage capacitor is charged to 3.5 V. The PSoC pulls a general-purpose input/output (GPIO) pin high after starting the main processor to wake up the two instrumentation amplifiers from sleep. The PSoC's embedded 12-bit ADC (analog-to-digital converter) samples following instrumentation amplifier initialization. An average of 32 potentiometric measurements are acquired via the instrumentation amplifiers. After ADC measurements, the instrumentation amplifiers are turned off to reduce power consumption. Then the 32-kHz watch crystal oscillator (WCO) starts and goes into deep sleep for 500 ms, consuming ~2 μA for accurate operation. The BLE stack is then initialized, and the ADC measurements are transmitted to the BLE observer user device. The integrated Bluetooth Low Energy (BLE) module allows sensor data to be easily transmitted to a mobile interface for tracking health status during exercise. The circuit only consumes an average of 330 μA over ~510 ms (168 μC) when powered with 2.2V.

References

A research paper describing the challenge, design, and outcome of the research