Hexagon CMM MAESTRO

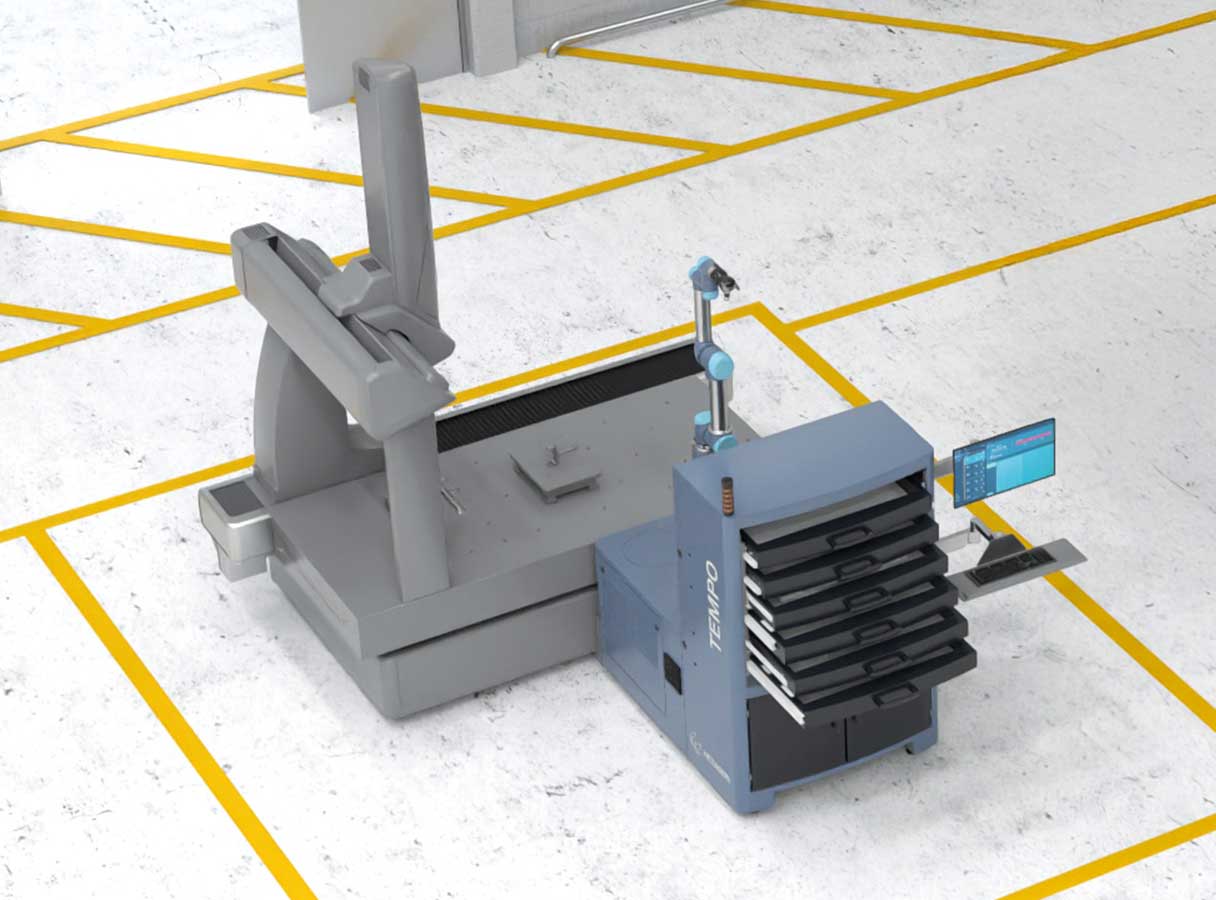

High-Speed, Multi-Sensor CMM System for Precision Metrology and Automation

General

| Product Type | Measurement & Testing Equipment |

| Applications | Manufacturing |

| Key Features | Metrology, CMM |

Technical Specifications

| Measuring System | METALLUR® Linear Scales, 0.0003 µm Resolution |

| RAM Counterbalance | Pneumatic, Adjustable |

| Maximum 3D Speed | Standard: 700 mm/s; With Throughput+: Up to 1,100 mm/s |

| Max 3D Acceleration | Up to 6,500 mm/s² (with Throughput+) |

| Sensors Supported | DTT B (Touch Trigger), DST 200 (Scanning), DSL 100 (Laser) |

| Power Supply | 100–240 V ±10%, 50/60 Hz, 0.5 kVA constant |

| Air Supply | ≥ 0.5 MPa, 90 Nl/min |

| Temperature Compensation | Extended T: 16 - 26 °C: Multi-Sensor Technology |

| Software | PC-DMIS, Metrology Mentor, Metrology Asset Manager, Metrology Reporting |

Overview

The MAESTRO CMM system is an all-digital, fully connected CMM system, purpose-built for metrology and modern manufacturing applications. It features micromachined anodized light alloy extrusions for the X and Z axes, and integral dovetail guideways machined into the table for the Y axis. The system utilizes air bearings on all axes for sliding motion and METALLUR linear scales with a 0.0003 μm resolution for measurement.

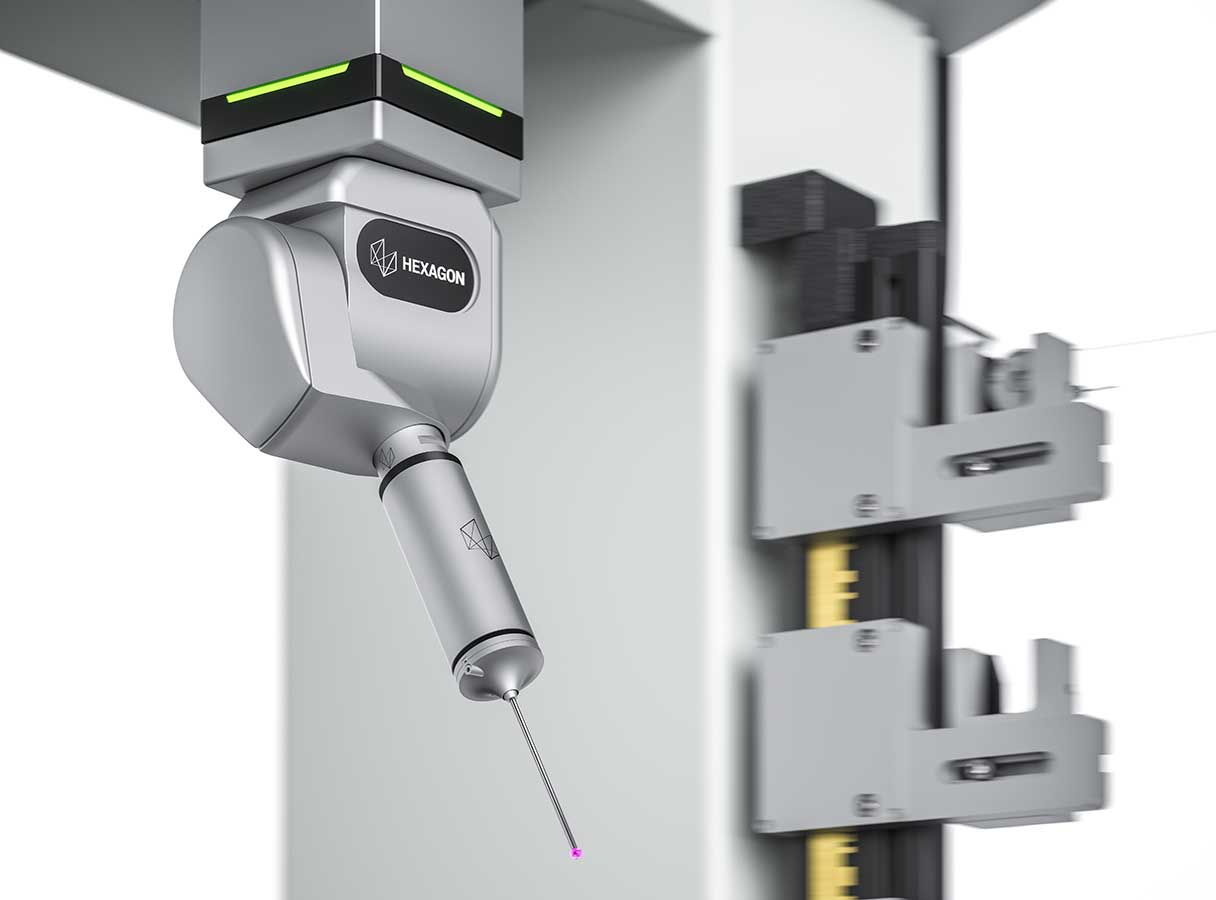

MAESTRO offers various configurations, including MAESTRO Touch+, MAESTRO Scan+, and MAESTRO Speed. These configurations integrate digital sensors, including the DW 2.5 digital wrist, DTT B digital touch trigger probe, DST 200 digital scanning probe, and DSL 100 digital laser scanner. The integrated controller eliminates the need for an external cabinet, and the system is designed for field upgrades, supporting future feature expansion and extended equipment life.

Hexagon MI CMM MAESTRO Features

No matter what you’re inspecting, MAESTRO empowers users to measure faster, collaborate smarter, and unlock real-time quality insights — all within a scalable, future-ready platform. Let’s explore its features in detail:

Hardware Highlights & Architecture

The MAESTRO CMM system operates as an all-digital, IIoT-enabled measuring device, designed for integration within connected manufacturing environments. Its architecture features an integrated controller located at the rear of the system, which reduces external cabling and simplifies setup.

Smart Machine Eye (SME)

The system supports seamless connectivity with major industrial automation ecosystems via an Ethernet-based Metrology Communication Interface, enabling the exchange of data and the remote triggering of measuring operations. A built-in camera system, Smart Machine Eye (SME), provides remote visual access for collision monitoring and enhanced troubleshooting. Status LEDs on the Z-tower and sensor interface, along with a display, provide operational status and detailed warnings.

Measurement Performance & Sensor Technology

The MAESTRO CMM offers volumetric length measurement errors (E0/E150) as low as 1.2+L/350μm at 22°C and a repeatability range (RO) of 1.0 μm for specific configurations. It achieves maximum 3D speeds of up to 1100 mm/s and maximum 3D accelerations of up to 6500 mm/s2 with the Throughput+ option. Sensor options include the DW 2.5 digital wrist, which provides infinite 360° B-axis rotation with 2.5° angular steps, resulting in 12,240 unique positions.

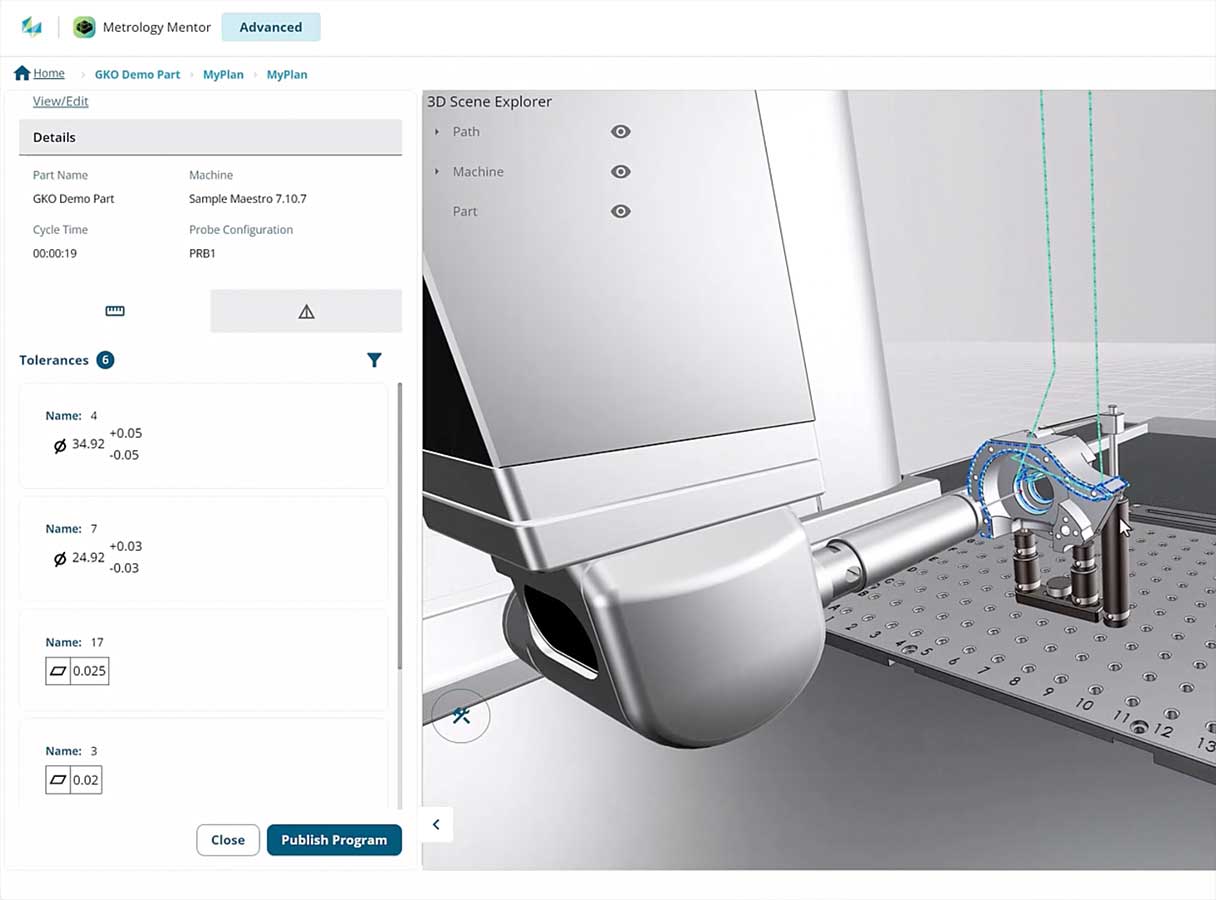

Digital Changer Rack

Probes such as the DTT B digital touch-trigger probe, DST 200 digital scanning probe (with <0.1μm resolution and 2 mm measuring range), and DSL 100 digital laser scanner (Class 2, 300 Hz scanning frequency, 600,000 pts/sec data rate) are supported. The automated sensor exchange is facilitated by a digital changer rack that integrates with a digital twin for real-time monitoring of port status and occupancy.

Software Ecosystem & Functionality

The system leverages a comprehensive software suite for metrology operations. PC-DMIS serves as the primary metrology software, offering programming capabilities for routine creation and execution, adhering to ASME Y14.5 and ISO 1101 standards.

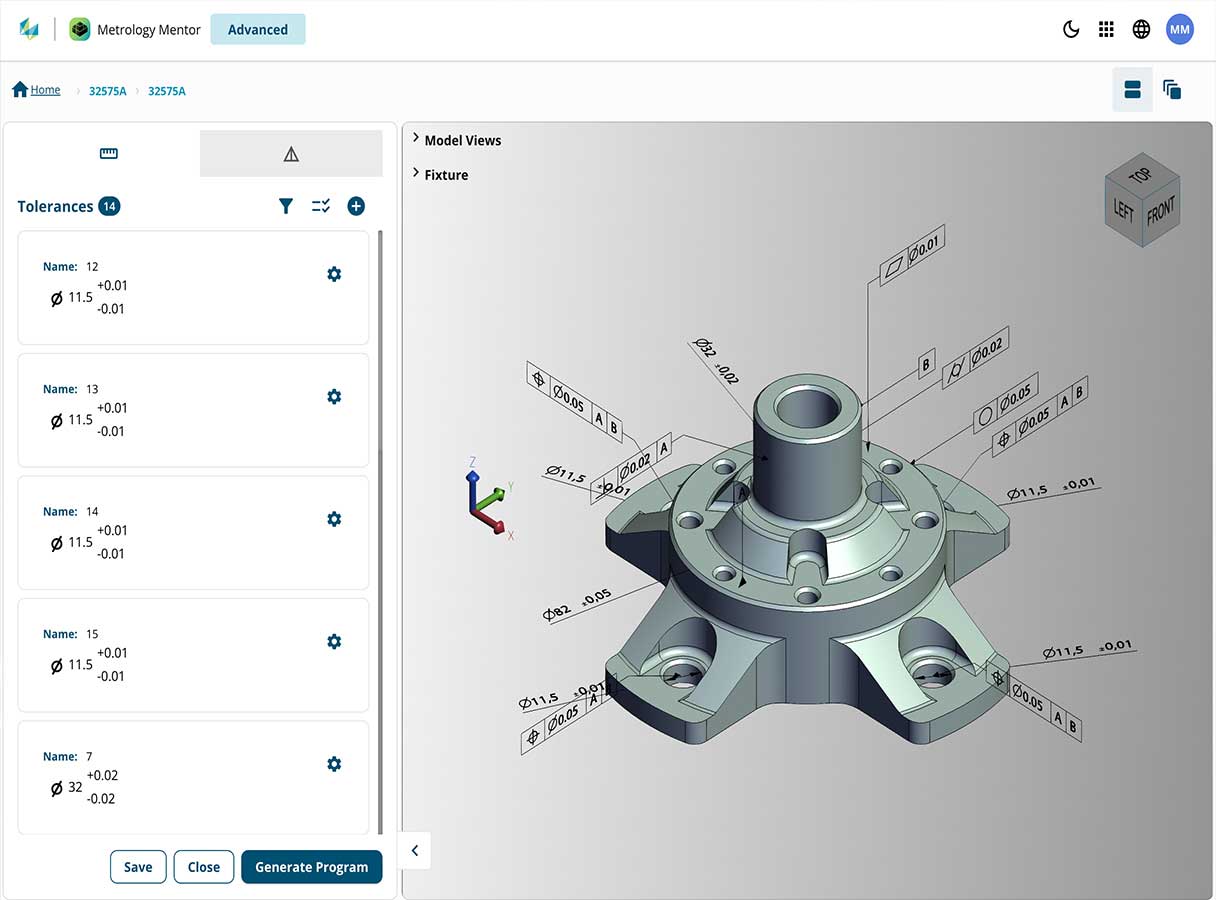

Metrology Mentor

Metrology Mentor automates CMM programming, generating collision-free programs from PMI data with minimal user input.

Environment Builder

Environment Builder, an embedded software component, manages the digital twin of the machine environment, supporting the creation, calibration, and alignment of probes.

FastCal Calibration

FastCal Calibration reduces calibration time by determining multiple probe angles and head positions in a single automated operation.

Metrology Communication Interface

Metrology Communication Interface seamlessly connects MAESTRO to ERP, MES, and PLC systems, enabling real-time data exchange and remote control for easy integration and automation.

Mechanical & Environmental Specifications

MAESTRO CMMs are available in various frame sizes. The mechanical frame consists of micromachined anodized light alloy extrusions for X and Z axes, with integral dovetail guideways machined into the Y-axis table. Air bearings are used on all axes for the sliding system.

Measurement is performed using METALLUR linear scales with an overall system resolution of 0.0003μm. Temperature compensation is extended to ambient temperatures ranging from 6°C to 26°C using multi-sensor technology. Electrical power requirements are 100−120/220−240 V±10, with a constant consumption below 0.5 kVA. Air supply requires ≥0.5 MPa (5 bar) with consumption less than 70 Nl/min (for 05.07.05 and 07.10.07 sizes) or 90 Nl/min (for 09.YY.08 size).

Models and Configurations

1. MAESTRO Touch+

MAESTRO Touch+

General-purpose measurements of size features with highly repeatable touch-trigger probing.

DTT B digital touch trigger probe

PC-DMIS CAD metrology software

2. MAESTRO Scan+

MAESTRO Scan+

General-purpose measurements of size and form features with high-performance tactile scanning.

DST 200 digital scanning probe

PC-DMIS CAD++ metrology software

Scan Pilot for improved scanning performance

3. MAESTRO Speed

MAESTRO Speed

High-throughput measurements of complete part surfaces with high measuring point density.

Digital scanning laser sensor DSL

PC-DMIS CAD++ metrology software

Scan Pilot for improved scanning performance, DR Digital Rack, including modules for DSL

The MAESTRO system remains in top condition for lasting performance and peace of mind with the MyCare service program by Hexagon.

Where to find it

Hexagon

Shaping Reality